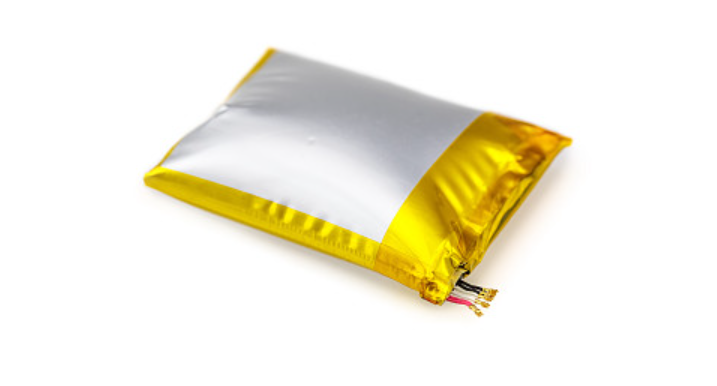

Dispose of swollen lithium batteries properly can mitigate fire hazards, environmental harm, and costly damage. As a cornerstone of modern technology, lithium batteries power everything from medical devices to renewable energy systems. However, when they swell due to internal failures, they become ticking time bombs. This guide explains why swelling occurs, its dangers, step-by-step disposal protocols, and innovations to prevent future risks—equipping you with the knowledge to handle swollen lithium batteries responsibly.

Why Do Lithium Batteries Swell?

Lithium batteries may swell for several reasons. Typically, the swelling is caused by internal gas buildup due to chemical reactions. Over time, factors such as overcharging, exposure to high temperatures, and manufacturing defects can accelerate these reactions. In some cases, using a charger that supplies an incorrect voltage or current can also contribute to battery degradation. Understanding these causes is key to preventing future occurrences.

The Dangers of Swollen Lithium Batteries

Swollen lithium batteries are not just unsightly—they pose significant safety risks. The main dangers include:

- Fire and Explosion Hazards: The internal chemical reactions can become uncontrollable, potentially leading to fires or explosions.

- Chemical Leakage: Damaged batteries may leak toxic chemicals, which can be harmful to both humans and the environment.

- Device Damage: Continued use of a swollen battery can damage your device’s internal components and may void warranties.

These hazards underscore the importance of proper lithium battery disposal. It is crucial to handle swollen batteries with care and to follow recommended safety procedures.

How to Safely Dispose of Swollen Lithium Batteries: Protocols for Industry Professionals

For engineers, facility managers, and hazardous waste specialists, knowing how to dispose of swollen lithium batteries is not just a precaution—it’s a regulatory and operational imperative. Swollen lithium-ion batteries pose significant risks of thermal runaway, toxic chemical release, and regulatory non-compliance. Below is a technical framework aligned with OSHA, NFPA, and IEC standards to ensure safe handling and disposal.

Step 1: Immediate Isolation and Risk Assessment

- De-energize and Quarantine

-

Disconnect the battery from devices using insulated tools (e.g., ceramic-tipped pliers).

-

Place the battery in a UN-certified fireproof container (e.g., Li-ion fire containment bags) filled with inert materials like vermiculite or sand to suppress potential ignition.

-

Label the container with hazard symbols (e.g., “Class 9 Hazard”) per DOT/UN 3480/3481 guidelines.

-

- Risk Evaluation

-

Assess swelling severity using non-invasive methods (e.g., thermal imaging to detect hotspots or gas sensors to monitor off-gassing).

-

Document the battery’s state, including voltage readings (if safe to measure) and physical deformities, for compliance reporting.

-

Step 2: Personal Protective Equipment (PPE) and Containment

-

Mandatory PPE:

- Flame-resistant (FR) clothing (NFPA 2112/2113 compliant).

- Chemical-resistant gloves (nitrile or neoprene) and face shields with side protection.

- Respirators with organic vapor cartridges if electrolyte leakage is suspected.

-

Secondary Containment:

- Store quarantined batteries in ventilated, temperature-controlled cabinets (≤25°C) away from oxidizers or combustibles.

- For large-scale storage (e.g., EV battery packs), use explosion-proof battery cabinets with integrated gas venting systems.

Step 3: Professional Transport and Recycling

- Certified Logistics

- Engage transporters licensed under RCRA Subtitle C for hazardous waste.

- Use UN-approved packaging (e.g., UN 4G/X fiberboard boxes with inner liner bags) and ground shipping only—air transport is prohibited for swollen batteries.

- Recycling Compliance

- Partner with R2v3- or e-Stewards-certified recyclers to ensure full traceability and compliance with EPA’s Resource Conservation and Recovery Act (RCRA).

- Prioritize facilities with hydrometallurgical recycling systems, which recover >95% of lithium, cobalt, and nickel with minimal environmental impact.

Step 4: Documentation and Incident Reporting

-

Maintain records of:

- Battery origin (manufacturer, batch number).

-

Hazard assessment reports (swelling cause, voltage decay data).

DIY Guide for Disposing of Swollen Lithium Batteries

Step 1: Recognize the Warning Signs

Act immediately if you notice:

-

Visible bulging: The battery casing appears warped or pushes against the device cover.

-

Device malfunction: Sudden shutdowns, failure to charge, or overheating.

-

Odors: A sweet or metallic smell (indicating electrolyte leakage).

Step 2: Power Down and Isolate the Battery

-

Turn off the device: Unplug it and press the power button until it shuts down.

- Remove the battery (if possible):

- Use plastic tools (e.g., guitar picks or credit cards) to avoid metal contact.

- For non-removable batteries (e.g., smartphones): Place the entire device in a safe container.

- Avoid sparks: Do not charge or attempt to use the device again.

Step 3: Prepare a Safe Storage Container

Materials you’ll need:

- A metal bucket with a lid (or thick plastic container rated for chemicals).

-

Inert absorbent material: Sand, cat litter, or baking soda (to neutralize leaks).

-

Heavy-duty gloves (rubber or nitrile) and safety goggles.

Instructions:

- Line the container with 2–3 inches of absorbent material.

- Place the battery (or device) in the center, ensuring no contact with metal surfaces.

- Cover with another layer of absorbent material and seal the lid.

-

Label the container clearly: “Swollen Lithium Battery—Do Not Open.”

Pro Tip:

Store the container in a cool, dry place like a garage or shed—never in living areas or near heat sources.

Step 4: Transport to a Recycling Center

Do NOT throw swollen batteries in the trash or regular recycling bins.

- Find a certified drop-off location:

-

Use Call2Recycle’s locator tool or check with local electronics retailers (e.g., Best Buy, Home Depot).

-

- Prepare for transport:

- Keep the sealed container upright and secure it in your vehicle’s trunk or cargo area.

-

Avoid extreme temperatures (e.g., don’t leave it in a hot car).

How to Avoid Lithium Battery Swelling

Prevention is always better than cure. Here are some practical tips to avoid battery swelling:

- Use Manufacturer-Approved Chargers: Always charge your devices using the recommended charger to prevent overcharging.

- Avoid Extreme Temperatures: Keep your batteries away from direct sunlight and avoid leaving devices in hot environments.

- Regular Inspections: Periodically check your batteries for any signs of damage or swelling.

- Proper Storage: If you’re storing a device for a long period, ensure the battery is charged to around 40-60% and stored in a cool, dry place.

- Update Firmware: Some modern devices have smart charging features. Ensure your device’s firmware is up-to-date to benefit from these safety enhancements.

Frequently Asked Questions (FAQs)

-

What causes lithium batteries to swell?

Lithium batteries swell primarily due to internal gas buildup caused by overcharging, high temperatures, or manufacturing defects. -

Are swollen lithium batteries dangerous?

Yes, they are. Swollen batteries can lead to fires, explosions, and chemical leaks, posing risks to both personal safety and the environment. -

What are the best practices to avoid battery swelling?

Use approved chargers, avoid extreme temperatures, regularly inspect batteries, and store them properly to prevent swelling. -

How is battery recycling improving?

Advances in recycling technology are focusing on more efficient recovery of materials and reducing environmental impact, making recycling processes safer and more sustainable.

Conclusion

Dealing with a swollen lithium battery requires careful attention and adherence to safety protocols. Whether you choose to handle the disposal yourself or seek professional help, understanding the causes, risks, and best practices is essential. By following the guidelines provided in this article, you can ensure safe battery handling and contribute to a greener, more sustainable future.