“Batteries in series vs parallel” is a fundamental concept for anyone designing or optimizing custom energy systems. Whether you’re powering an electric vehicle, a solar farm, or a portable device, understanding these configurations ensures optimal performance, safety, and cost-efficiency.

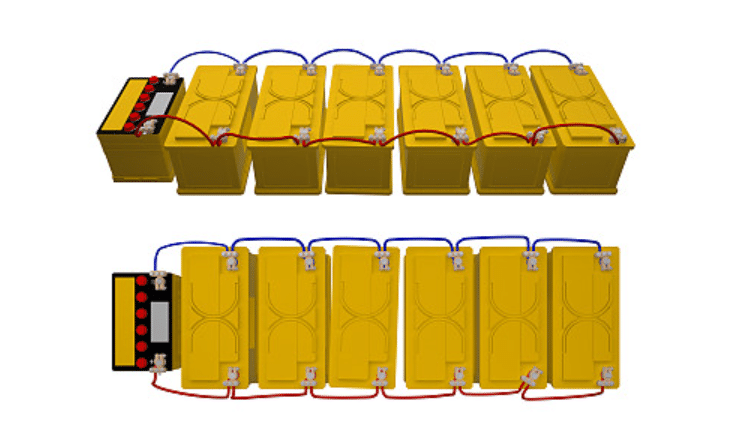

Series Connection of Batteries

In a series connection, the positive terminal of one battery is connected to the negative terminal of the next. This configuration results in a higher total voltage, which is the sum of each individual battery’s voltage, while the capacity (Ah) remains the same as a single battery.

Advantages of Series Connection

-

Higher Voltage for High-Power Applications

- Devices requiring higher voltage, such as electric vehicles (EVs), power tools, and solar energy storage, benefit from a series connection because it allows them to operate efficiently without excessive current draw.

-

Reduced Current Load on Wires and Components

- By increasing the voltage instead of the current, a series connection helps reduce energy losses due to resistance in wires and components, which improves overall efficiency in a power system.

-

Efficient Charging in High-Voltage Applications

- Many charging systems, such as EV chargers and large-scale battery management systems, are optimized for high-voltage battery packs, making series configurations more suitable.

-

Better Power Distribution in Large-Scale Applications

- Series configurations allow for balanced power distribution, ensuring each battery in the system contributes equally to the total power output.

Disadvantages of Series Connection

-

Battery Imbalance Issues

- Over time, individual batteries may develop slight capacity variations, causing some to reach full charge before others. This imbalance can lead to overcharging or deep discharging, potentially shortening battery lifespan if not managed properly with a battery management system.

-

Complete System Failure if One Battery Fails

- If one battery in the series fails or becomes disconnected, the entire circuit is broken, causing the system to stop working unless a bypass circuit is in place.

-

Increased Complexity in Charging

- Charging a series-connected battery pack requires a balanced charging system to prevent individual cells from being overcharged or undercharged, which can be challenging in large battery setups.

-

Higher Internal Resistance

- The internal resistance of each battery adds up in a series connection, which can result in higher heat generation and energy loss if not properly managed.

Parallel Connection of Batteries

In a parallel configuration, the positive terminals of all batteries are connected together, and the negative terminals are also connected together. This setup maintains the same voltage as a single battery but increases the capacity (Ah) by summing up the capacities of all connected batteries.

Advantages of Parallel Connection

-

Increased Battery Capacity for Longer Runtime

- Since the capacity (Ah) is additive, a parallel battery pack can provide longer-lasting power, making it ideal for devices requiring extended battery life, such as backup power systems (UPS), solar power storage, and portable electronics.

-

Improved System Redundancy and Reliability

- Unlike a series connection, if one battery fails in a parallel configuration, the system can still function, drawing power from the remaining operational batteries. This enhances reliability in critical applications like medical devices and emergency power backups.

-

Lower Current Draw per Battery

- Since the total current is distributed among multiple batteries, each individual battery experiences less current draw, reducing heat generation and stress on the cells, which prolongs battery lifespan.

-

Simpler Charging Process

- Charging a parallel battery setup is generally easier and safer, as the voltage remains the same as a single cell. Standard chargers can be used without needing complex balancing circuits like those required in series configurations.

Disadvantages of Parallel Connection

-

Limited Voltage Output

- Since parallel connections do not increase voltage, applications that require high-voltage power supplies may not be suitable for a pure parallel setup without additional circuitry.

-

Unequal Current Distribution Among Batteries

- If batteries have different internal resistances or are at different charge levels, they may unevenly share the load, leading to some batteries discharging or charging faster than others, which can cause premature degradation.

-

Potential for Overcurrent Issues

- If one battery in a parallel setup has a short circuit, it can cause a high current draw from the other batteries, potentially damaging the entire system unless proper fuses or protection circuits are in place.

-

More Wiring and Space Requirements

- While parallel configurations improve battery life, they require more connections and physical space due to the need for additional batteries to achieve the desired capacity.

Differences Between Series and Parallel Battery Configurations

When choosing between series and parallel battery configurations, it’s crucial to understand how they impact voltage, current, capacity, efficiency, performance, and safety. Below is a detailed comparison of the key differences:

1. Voltage Output

-

Series Connection:

- The voltage increases as batteries are connected in series.

- The total voltage is the sum of the individual cell voltages.

- Formula: Vtotal=V1+V2+V3+…+Vn

- Example: Connecting four 3.7V lithium-ion batteries in series results in a 14.8V pack.

- Best for: Applications requiring higher voltage such as electric vehicles (EVs), power tools, and industrial equipment.

-

Parallel Connection:

- The voltage remains the same as a single cell regardless of how many batteries are connected.

- Formula: Vtotal=Vsingle battery

- Example: Connecting four 3.7V batteries in parallel still results in 3.7V output.

- Best for: Applications where high capacity and longer runtime are needed, such as power banks, solar energy storage, and medical devices.

2. Current Capacity (Amperage)

-

Series Connection:

- The current remains the same as a single battery.

- Formula: Itotal=Isingle battery

- Example: If each battery provides 2Ah, the total capacity remains 2Ah in a series connection.

- Limitation: Since the total current does not increase, high-power applications may require thicker wires or more efficient circuit designs to handle the power demand.

-

Parallel Connection:

- The total current capacity increases, as the capacities of all connected batteries are added together.

- Formula: Itotal=I1+I2+I3+…+In

- Example: If four 2Ah batteries are connected in parallel, the total capacity becomes 8Ah, allowing longer operation.

- Best for: Devices requiring long runtime without increasing voltage, such as laptops, tablets, and renewable energy storage systems.

3. Battery Capacity (Ah) and Runtime

-

Series Connection:

- The total capacity (Ah) remains the same as a single battery.

- Formula: Ctotal=Csingle battery

- Impact: The runtime of the system does not increase significantly, unless voltage conversion (such as using a DC-DC converter) is used to optimize efficiency.

-

Parallel Connection:

- The capacity (Ah) increases, meaning longer battery life before recharging is needed.

- Formula: Ctotal=C1+C2+C3+…+Cn

- Impact: Higher capacity means longer runtime, which is especially useful for backup power systems, medical equipment, and communication devices.

4. Internal Resistance and Efficiency

-

Series Connection:

- The internal resistance adds up, which can reduce efficiency and generate more heat.

- Higher resistance leads to energy losses during power transmission, especially in high-voltage applications.

- Efficiency can be improved with proper battery management systems (BMS) and equalization circuits.

-

Parallel Connection:

- The internal resistance decreases, making power delivery more efficient with lower heat generation.

- Less energy is lost, which is beneficial for high-efficiency systems like solar energy storage.

- Requires balanced charging circuits to avoid uneven current distribution.

5. Charging Characteristics

-

Series Connection:

- Requires a balanced charger to ensure all batteries charge evenly.

- If one battery becomes overcharged or undercharged, it can degrade faster, reducing overall pack life.

- More complex battery management system is needed to monitor and regulate charging.

-

Parallel Connection:

- Easier to charge because all batteries share the same voltage.

- However, current imbalances may occur if batteries have different internal resistances.

- If one battery is weaker, the others may overcompensate, leading to uneven wear.

6. Safety Considerations

-

Series Connection:

- If one battery fails or degrades, it can affect the entire pack, leading to potential voltage instability.

- Higher voltages can increase the risk of electric shock or thermal runaway if not properly managed.

- Needs a Battery Management System to protect against overcharging, overheating, and voltage imbalances.

-

Parallel Connection:

- A failed battery in a parallel setup does not disrupt the entire system, increasing overall reliability.

- Risk of overcurrent if one battery shorts out, requiring fuses or current-limiting circuits to prevent damage.

- More space is needed for extra wiring and protection circuits.

7. Common Applications

| Configuration | Best Used For | Example Applications |

|---|---|---|

| Series | High voltage applications | Electric vehicles (EVs), power tools, drones, industrial machinery |

| Parallel | Long runtime and high capacity | Solar storage, power banks, UPS (Uninterruptible Power Supplies), medical equipment |

| Series-Parallel | Balanced voltage and capacity | Hybrid energy storage systems, large-scale battery packs, grid backup power |

Which Configuration Should You Choose?

Choose Series if:

✅ You need higher voltage (e.g., 24V, 48V systems).

✅ Your application requires high power output with a lower current.

✅ You are using DC motors, industrial equipment, or high-voltage battery packs.

Choose Parallel if:

✅ You need longer battery life and high capacity.

✅ You want more reliable operation, even if one battery fails.

✅ Your application includes solar storage, backup power, or portable devices.

Choose Series-Parallel if:

✅ You need both higher voltage and increased capacity.

✅ Your system requires balanced power and runtime efficiency.

✅ You are building custom battery solutions for applications like electric motorcycles, hybrid energy systems, or grid backup.

Common FAQs

-

Can I mix different types of batteries in series or parallel?

It’s not recommended to mix different types, capacities, or ages of batteries, as this can lead to imbalance, reduced performance, and potential safety hazards.

-

What happens if one battery in a series configuration fails?

A failed battery can disrupt the entire circuit, leading to reduced performance or complete failure of the device.

-

Is battery balancing necessary for parallel configurations?

While parallel configurations naturally balance to some extent, significant differences in cell voltages or capacities can cause issues, making monitoring important.

-

How does temperature affect series and parallel battery configurations?

Extreme temperatures can impact battery performance and lifespan in both configurations. It’s crucial to operate batteries within their specified temperature ranges.

-

Can I add more batteries to an existing series or parallel setup?

Adding batteries to an existing setup should be done cautiously, ensuring compatibility in terms of type, capacity, and age to prevent imbalance and potential damage.