From raw materials to the final product, this video walks you through each crucial step, revealing how a custom lipo battery is made.

What is a Custom Lipo Battery?

Battery customization is a technologically driven process that begins with assessing the specific needs of each customer to design a new battery model. Unlike traditional standardized cylindrical batteries, such as 18650 or 21700 cells, customization requires careful consideration of the manufacturing process, material quality control, and the manufacturer’s experience with similar projects. Typically, a custom battery is designed based on key requirements provided by the customer.

Lipo Battery Manufacturing Phase 1: Electrodes

1. Slurry Mixing

Slurry mixing marks the initial step in battery manufacturing, similar to preparing batter for a cake. In this stage, a vacuum mixer is used to combine active materials—such as lithium cobalt oxide or lithium manganese oxide for the cathode, and graphite for the anode—with conductive additives like carbon black and binders such as PVDF. A solvent, either NMP or a water-based alternative, is added in carefully measured amounts to create a homogeneous slurry with a precise viscosity, ready for coating onto the electrode substrate.

Role in the battery manufacturing process:

Ensures uniform distribution of active materials and additives, which is critical for consistent electrochemical performance across the electrode.

Controls the viscosity and flow properties of the slurry, allowing smooth and even coating onto current collectors.

Promotes strong adhesion between the active material and the current collector, preventing delamination during cycling.

Contributes to the overall energy density and performance of the battery by creating electrodes with optimal microstructure and porosity.

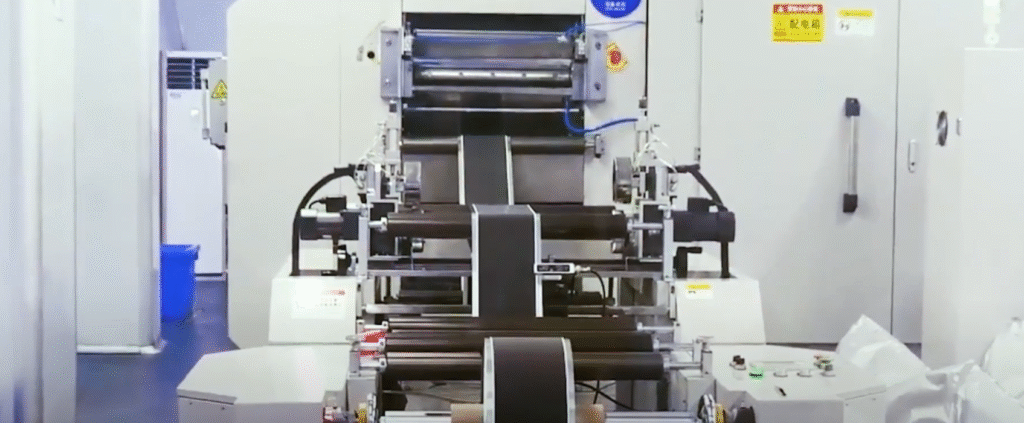

2. Coating

The prepared slurry is evenly applied onto a metal current collector using a precision coating machine. For the cathode, the slurry is coated onto aluminum foil, while the anode slurry is applied to copper foil. This step ensures a consistent layer thickness and uniform material distribution, which are critical for the battery’s performance.

Role in the battery manufacturing process:

Creates a uniform electrode layer: Ensures even distribution of active materials across the current collector, which is essential for consistent electrochemical performance.

Controls electrode thickness and loading: Precise coating determines the amount of active material per unit area, directly affecting the battery’s capacity and energy density.

Promotes adhesion: Helps the active material bond securely to the current collector, preventing peeling or delamination during cycling.

Influences battery efficiency and lifespan: A well-coated electrode reduces internal resistance and enhances overall battery stability and durability.

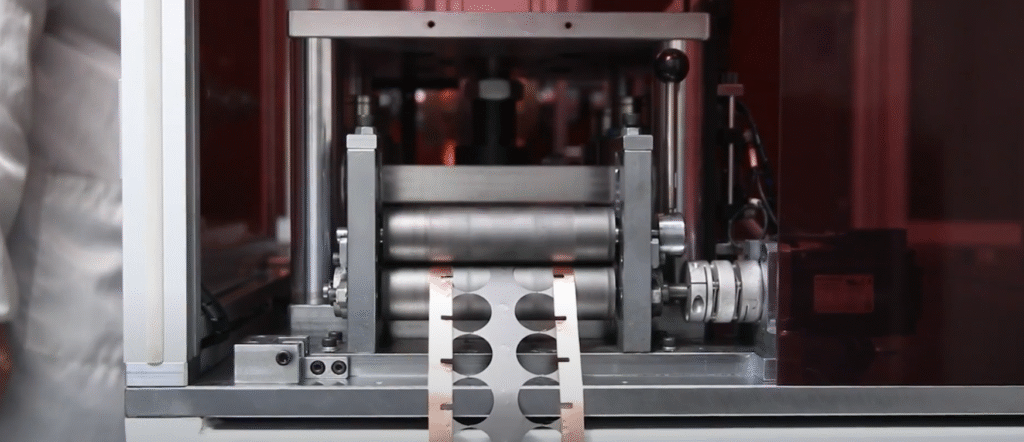

3. Calendering

After the electrode sheets are dried, they are fed through a pair of high-precision rollers in a process known as calendering. This step compresses the electrode coating, increasing the packing density of the active material and improving the mechanical integrity of the electrode.

Role in the battery manufacturing process:

Enhances energy density: By increasing the packing density of active materials, more electrochemically active material can fit into the same electrode volume, directly boosting the battery’s capacity.

Improves electrode uniformity: Rolling ensures a consistent thickness and surface smoothness, which is critical for stable electrochemical performance and efficient ion transport.

Strengthens mechanical stability: Compacted electrodes are less prone to cracking, delamination, or deformation during assembly and cycling.

Optimizes battery efficiency: Proper calendering reduces internal resistance and supports uniform current distribution, contributing to longer battery life and better performance.

4. Slitting

The large master roll of electrode sheet is slit into narrower rolls that match the specified cell width. At the same time, welding tabs are precisely stamped or laser-cut according to the battery’s design dimensions, ensuring accurate alignment and reliable connections for the next assembly steps.

Lipo Battery Manufacturing Phase 2: Assembling the Cell

5. Stacking(Lamination)

This step highlights a key feature that sets lithium-polymer (LiPo) batteries apart from traditional cylindrical lithium-ion cells. In this process, automated equipment—or in some cases skilled technicians—carefully layer the positive electrode, separator, negative electrode, and another separator in a precise “sandwich” configuration. The separator serves as an electrical insulator, preventing direct contact and short circuits between the electrodes while still allowing lithium ions to flow freely during charge and discharge.

Role in the battery manufacturing process:

Defines cell architecture: Accurate stacking determines the internal structure of the pouch cell, directly influencing energy density and overall capacity.

Ensures safety and reliability: Proper alignment of electrodes and separators minimizes the risk of internal short circuits and thermal runaway.

Supports high-performance cycling: Uniform layering promotes even current distribution and consistent ion transport, which improves cycle life and reduces capacity fade.

Enables flexible form factors: Because sheets can be stacked to varying thicknesses and shapes, this method supports the thin, lightweight designs typical of LiPo batteries used in drones, wearables, and other compact devices.

6. Welding

All positive electrode tabs from the stacked cell are joined to create the cell’s positive terminal, while all negative tabs are similarly welded to form the negative terminal. High-precision techniques such as ultrasonic or laser welding are typically used to ensure strong, low-resistance connections that maintain electrical conductivity and mechanical stability throughout the battery’s life cycle.

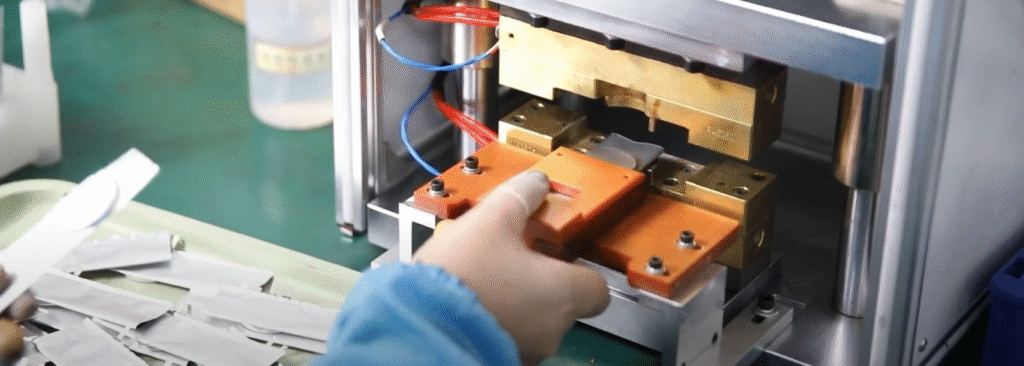

7. Pouch Forming & Sealing

The welded cell tabs are carefully inserted into a pre-formed aluminum-laminate pouch. Using a heat-sealing process, the pouch is then sealed along the top and side edges, leaving a single opening that will later be used for electrolyte filling. This step protects the cell stack from contamination and prepares it for the electrolyte injection stage.

Lipo Battery Manufacturing Phase 3: Activation and Testing

8. Electrolyte Injection

Inside a glove box or dry room where humidity is tightly controlled, a carefully measured volume of electrolyte is introduced into the baked cell through the remaining open port of the pouch. The electrolyte serves as the critical medium that enables lithium ions to move between the cathode and anode during charging and discharging, ensuring efficient electrochemical performance.

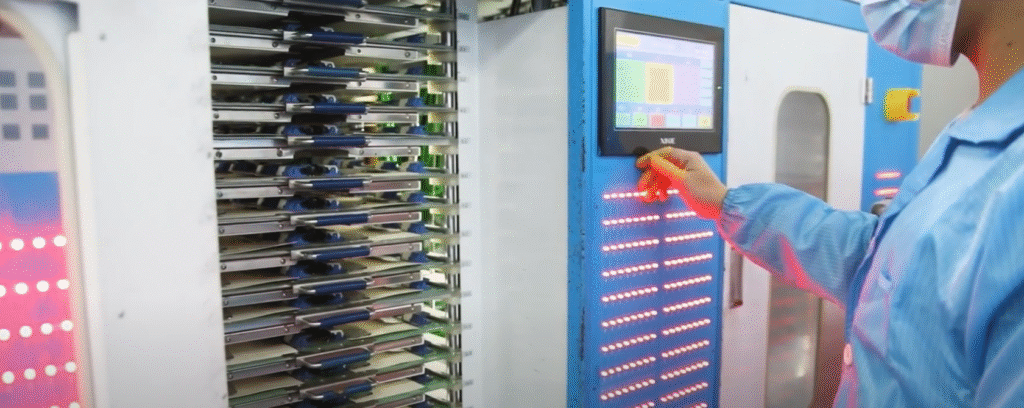

9. Formation

This critical stage in LiPo battery manufacturing marks the cell’s first controlled charge–discharge cycle after electrolyte injection. During the initial charge, the electrolyte undergoes a reaction with the anode surface, creating a thin, stable Solid Electrolyte Interphase (SEI) layer that protects the electrode and ensures long-term performance.

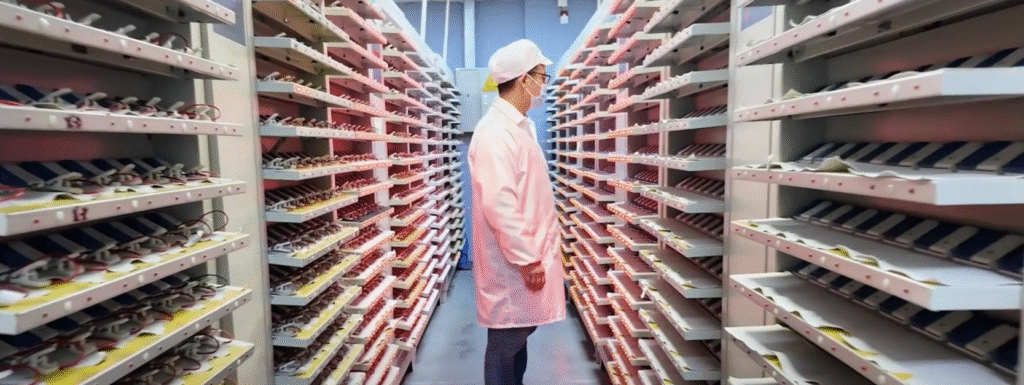

10. Aging

Aging is a controlled resting stage in the LiPo battery manufacturing process. During this period, internal chemical reactions—such as the continued stabilization of the SEI layer—progress and reach equilibrium. It’s comparable to allowing a freshly bottled wine to mature, ensuring the battery’s performance and reliability are fully stabilized before final testing and shipment.

11. Capacity Grading

Grading & Sorting is performed after capacity testing to classify batteries by performance. Cells are evaluated for slight variations in capacity, internal resistance, voltage, and other key parameters, then grouped into categories—such as Grade A or Grade B—to ensure consistency in quality and application.

12. Final Test

Each battery undergoes comprehensive checks, including appearance inspection, dimensional verification, and safety tests such as overcharge, short-circuit, and leakage assessments. This ensures that only cells meeting strict performance and safety standards reach customers.

Conclusion

LiPo battery manufacturing is a highly coordinated process, where every stage functions like a finely tuned gear—each one essential to the final product’s performance, lifespan, and safety. From the precise slurry formulation to the critical formation step, even the smallest deviation can lead to significant consequences. Mastery of these complex procedures is what allows LiPo batteries to deliver reliable, high-energy power for today’s digital world.

As a custom lipo battery manufacturer, LanDazzle offers full-service customization—from battery cells and structural design to BMS integration—delivering complete solutions tailored to your exact requirements. Our team provides detailed, confidential project support and high-quality, comprehensive after-sales service.

For inquiries or custom battery solutions, contact LanDazzle team Today!