Table of Contents

The robotics industry is growing rapidly, from industrial automation and warehouse logistics to service and medical robots. As robots become more autonomous and mobile, reliable, high-performance batteries are more important than ever.

A robot battery determines its endurance, mobility, and efficiency. Choosing the right battery affects performance, safety, and lifespan, whether for a compact service robot or a heavy-duty industrial machine. This article compares the main robot battery types in 2025, highlighting their strengths, limitations, and ideal applications to help engineers and manufacturers make informed decisions.

Major Types of Robot Batteries in 2025

As robotics technology continues to advance, the choice of battery chemistry plays a decisive role in determining a robot’s performance, runtime, and design flexibility.

In 2025, several types of batteries remain dominant in the market — each offering unique advantages for different robotic applications.

1. Lithium-ion Batteries

Lithium-ion batteries are the most widely used power source for industrial and professional robots.

They deliver high energy density, excellent efficiency, and are based on mature, reliable technology, making them ideal for robots that operate continuously or require long runtimes.

However, they age faster under high temperatures or during frequent high-rate discharges, which can reduce their lifespan if not properly managed. With an optimized Battery Management System (BMS), Li-ion batteries remain a powerful and dependable choice for most robotic platforms.

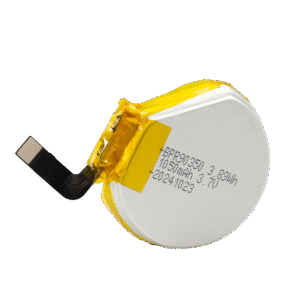

2. Lithium Polymer Batteries

Lithium polymer batteries have become increasingly popular in mobile and service robots that require lightweight, compact, and adaptable energy solutions.

Compared with cylindrical Li-ion cells, LiPo batteries provide flexible form factors, allowing them to fit into curved or ultra-thin robot designs.

They also offer high discharge rates and excellent power delivery, making them ideal for agile robots, drones, or delivery robots that perform frequent movements.

Although LiPo batteries are slightly more sensitive to overcharging and physical damage, their versatility and lightweight design make them one of the most promising power options for next-generation robotics.

3. Lithium Iron Phosphate (LiFePO₄) Batteries

LiFePO₄ batteries are renowned for their outstanding cycle life — often exceeding 2000 charge cycles — and excellent safety profile. They are among the most thermally and chemically stable lithium-based batteries, significantly reducing the risk of thermal runaway.

This makes them ideal for industrial robots, warehouse AGVs, and outdoor robotic systems that operate under demanding or high-temperature conditions.

While LiFePO₄ batteries are heavier and have slightly lower energy density than Li-ion or LiPo cells, their long lifespan, stable voltage output, and robust safety make them a preferred choice for mission-critical applications.

4. Nickel-Metal Hydride (NiMH) Batteries

NiMH batteries were once a common power source for robotics due to their low cost and ease of availability.

However, as lithium-based technologies became more affordable, NiMH batteries have been gradually phased out from most professional applications.

They still provide moderate safety and acceptable discharge performance, but their lower energy density and higher self-discharge rate limit their suitability for advanced robots.

Today, NiMH batteries are mainly used in educational robots, hobby projects, or low-power devices where affordability is the top priority.

Battery Comparison Table

| Battery Type | Energy Density | Cycle Life | Weight | Safety | Cost | Ideal Robot Applications |

|---|---|---|---|---|---|---|

| Li-ion | Very high | Long (500–1500 cycles) | Lightweight | Moderate | Moderate to high | Industrial robots, autonomous systems |

| LiPo | High | Long (500–1200 cycles) | Very lightweight | Moderate | Moderate | Service robots, delivery robots, compact designs |

| LiFePO₄ | Medium to high | Very long (2000+ cycles) | Heavier | Very high | Medium | Heavy-duty robots, outdoor AGVs, logistics robots |

| NiMH | Low | Moderate (500–800 cycles) | Heavy | Moderate | Low | Educational robots, hobby or entry-level projects |

Trends in Robot Battery Technology for 2025

As the robotics industry continues to evolve, battery technology is advancing rapidly to meet the demands of higher performance, longer runtime, and safer operation. In 2025, several key trends are shaping the way engineers and manufacturers select power solutions for robots.

1. Higher Energy Density and Advanced Chemistries

Next-generation lithium batteries, including silicon-carbon anodes and solid-state designs, are enabling significantly higher energy density compared to traditional Li-ion cells.

These innovations allow robots to operate longer on a single charge while maintaining compact and lightweight designs — a critical factor for mobile, service, and drone robots.

2. Smarter Battery Management Systems (BMS)

Intelligent BMS solutions are becoming standard in modern robot batteries.

These systems monitor cell voltage, temperature, and charge state in real time, optimizing performance and protecting the battery from overcharging, overheating, or deep discharge.

As a result, robots can operate more safely and efficiently, with extended battery lifespan.

3. Custom and Modular Battery Designs

Robots are increasingly built in unique form factors that demand custom-shaped or modular battery packs. Flexible LiPo solutions allow designers to integrate batteries into curved spaces or specialized compartments, while modular designs simplify maintenance and scalability for industrial robots or autonomous systems.

4. Sustainability and Long-Term Reliability

With growing emphasis on environmental responsibility, battery manufacturers are focusing on recyclable materials, longer cycle life, and safer chemistries.

LiFePO₄ and next-generation lithium chemistries are leading the way in combining high performance with eco-friendly design principles, ensuring that robots remain both powerful and sustainable.

5. Integration with AI and Smart Robotics

Battery performance is increasingly being optimized in conjunction with AI-driven energy management systems.

By predicting power consumption and adjusting load dynamically, robots can achieve maximum efficiency, reduce downtime, and improve overall operational reliability.

How to Choose the Right Battery for Your Robot

1. Determine Power and Runtime Requirements

The first step is to evaluate your robot’s energy consumption. High-power industrial robots or autonomous mobile robots often require Li-ion or LiFePO₄ batteries with long runtime and high discharge rates.

For smaller, lightweight service robots, LiPo batteries provide compact form factors and high discharge capacity suitable for agile movement and frequent short-duration operations.

2. Consider Size, Weight, and Design Constraints

Battery size and weight directly impact a robot’s mobility, balance, and payload capacity.

- For drones or mobile service robots, lightweight and flexible batteries like LiPo allow designers to maximize space and reduce overall mass.

- Heavy-duty robots with more space may prioritize LiFePO₄ batteries for durability and extended lifespan, even if they are slightly heavier.

3. Evaluate Safety and Reliability

Safety is paramount in robotic systems, especially in industrial or medical environments.

- LiFePO₄ batteries provide excellent thermal stability and minimal risk of thermal runaway.

- Properly designed Li-ion and LiPo batteries with integrated Battery Management Systems (BMS) can also offer high safety levels, protecting against overcharge, overdischarge, and overheating.

4. Assess Cycle Life and Maintenance Needs

The cycle life of a battery determines how long it can reliably operate before replacement.

- Industrial and outdoor robots benefit from long-cycle LiFePO₄ batteries, reducing maintenance costs over time.

- For educational or hobbyist robots, shorter-cycle LiPo or NiMH batteries may be sufficient and more cost-effective.

5. Factor in Cost and Availability

Finally, budget constraints and supplier reliability play an important role.

- While Li-ion and LiPo batteries offer high performance, they come at a moderate cost.

- NiMH batteries are low-cost but provide limited performance and are increasingly being phased out in professional robotics.

- Working with a trusted custom battery manufacturer ensures access to the right chemistry, certifications, and technical support.

Custom Robot Battery Solutions You Can Trust

When it comes to powering advanced robots, working with a reliable and experienced battery manufacturer is essential. LanDazzle specializes in custom lithium battery solutions designed to meet the unique requirements of modern robotic systems.

1. Expertise in Custom Robot Batteries

With years of experience in the lithium battery industry, We provide tailored battery packs for a wide range of robots — from compact service robots to heavy-duty industrial machines.

We offer Li-ion, LiPo battery chemistries, with custom voltage, capacity, shape, and BMS integration to optimize performance, safety, and longevity.

2. Advanced Design and Manufacturing

We operates its own R&D and manufacturing facilities, allowing precise control over every stage of battery production. Our engineers design modular and curved battery packs that fit complex robot architectures, ensuring efficient use of space without compromising energy density or reliability.

3. Safety and Certification

Our batteries are built with safety in mind and comply with UN38.3, CE, and RoHS certifications.

Integrated Battery Management Systems (BMS) provide real-time monitoring, preventing overcharge, overdischarge, and overheating, which is critical for both industrial and service robots.

4. Global Support and Collaboration

LanDazzle works with clients worldwide, offering technical support, fast prototyping, and scalable manufacturing.

Our custom robot batteries are designed to meet the demands of industrial automation, warehouse robotics, service robots, and autonomous systems, providing reliable power wherever it’s needed.

Conclusion

Choosing the right battery is crucial for any robot, whether it operates in industrial, service, logistics, or autonomous environments. By understanding the strengths and limitations of Li-ion, LiPo, LiFePO₄, and NiMH batteries, engineers and manufacturers can select a power solution that balances performance, safety, weight, and cost.

As we move into 2025, robot battery technology continues to evolve, with higher energy density, smarter Battery Management Systems (BMS), custom designs, and sustainable materials shaping the industry. Selecting a trusted custom battery manufacturer like LanDazzle ensures that your robots are powered by high-quality, reliable, and tailored battery solutions, optimized for efficiency and longevity.

With LanDazzle, you can achieve maximum robot performance, enhanced operational reliability, and long-term support for all your robotic applications.

Email: info@landazzle.com

Whatsapp: +8618938252128