In the rapidly evolving world of wearable technology, smart glasses are pushing the boundaries of design, functionality, and user expectations. But behind the sleek frames and cutting-edge displays lies a critical challenge that continues to puzzle engineers and manufacturers alike: smart glasses batteries.

Designing batteries for smart glasses is far more complex than it seems. Unlike smartphones or other wearables, smart glasses demand ultra-compact, lightweight, and precisely shaped batteries that still deliver long runtimes and meet strict safety standards—all within a form factor no thicker than a few millimeters. At the same time, power consumption is rising as features like AR displays, AI processing, and high-speed connectivity become standard.

In this article, we explore why smart glasses batteries are so difficult to get right—and how our custom battery solutions are solving these problems from the inside out.

The Unyielding Demands on Smart Glass Power

To appreciate why a custom solution is so critical, one must first understand the unique and conflicting demands placed upon smart glasses. Off-the-shelf, generic batteries were never designed for this kind of challenge.

The Miniaturization Dilemma

The first rule of smart glasses is that they must not feel “smart.” They need to be as light, comfortable, and aesthetically pleasing as traditional eyewear. The average pair of eyeglasses weighs a mere 25-30 grams. This creates an extreme constraint on space and weight, a domain where every millimeter and every gram counts. Standardized batteries, like small cylindrical or rectangular cells, are woefully inefficient. They leave unused gaps and force designers to compromise on either ergonomics or capacity. The “one-size-fits-all” approach simply fails, forcing a choice between a bulky, unfashionable device or one with an unacceptably short runtime.

The Insatiable Thirst for High-Tech Features

Smart glasses are marvels of miniaturized technology, but every component is thirsty for power. The cumulative drain is immense:

- Vibrant Displays: High-resolution microLED or OLED projectors are essential for a clear image, but they are a primary power consumer.

- Constant Connectivity: Persistent Bluetooth and Wi-Fi links to a smartphone or the cloud create a steady power trickle.

- Onboard Processing: The System-on-a-Chip (SoC) required for real-time AR overlays and sensor data fusion is a powerhouse that demands significant current.

- A Suite of Sensors: Cameras, microphones, accelerometers, and gyroscopes all require power to capture the data that makes the glasses “smart.”

These features don’t just require energy; they require it in quick, high-current bursts. A standard battery may not be able to deliver this peak power without a significant voltage drop, leading to sluggish performance or system shutdowns precisely when the user needs it most.

The Unseen Enemy: Heat

All this high-performance tech generates heat in a tiny, enclosed space with no room for fans or ventilation. This heat is not just uncomfortable for the wearer; it’s a critical threat to the battery. Heat increases a battery’s internal resistance, causing it to waste energy and operate inefficiently. More dangerously, it accelerates the chemical degradation of the cell, permanently shortening its lifespan and compromising its safety. A generic battery is not designed to manage the specific thermal load of a smart glass device, making it a weak link in the system.

The Solution is Custom: How LiPo Batteries Power the Future, Today

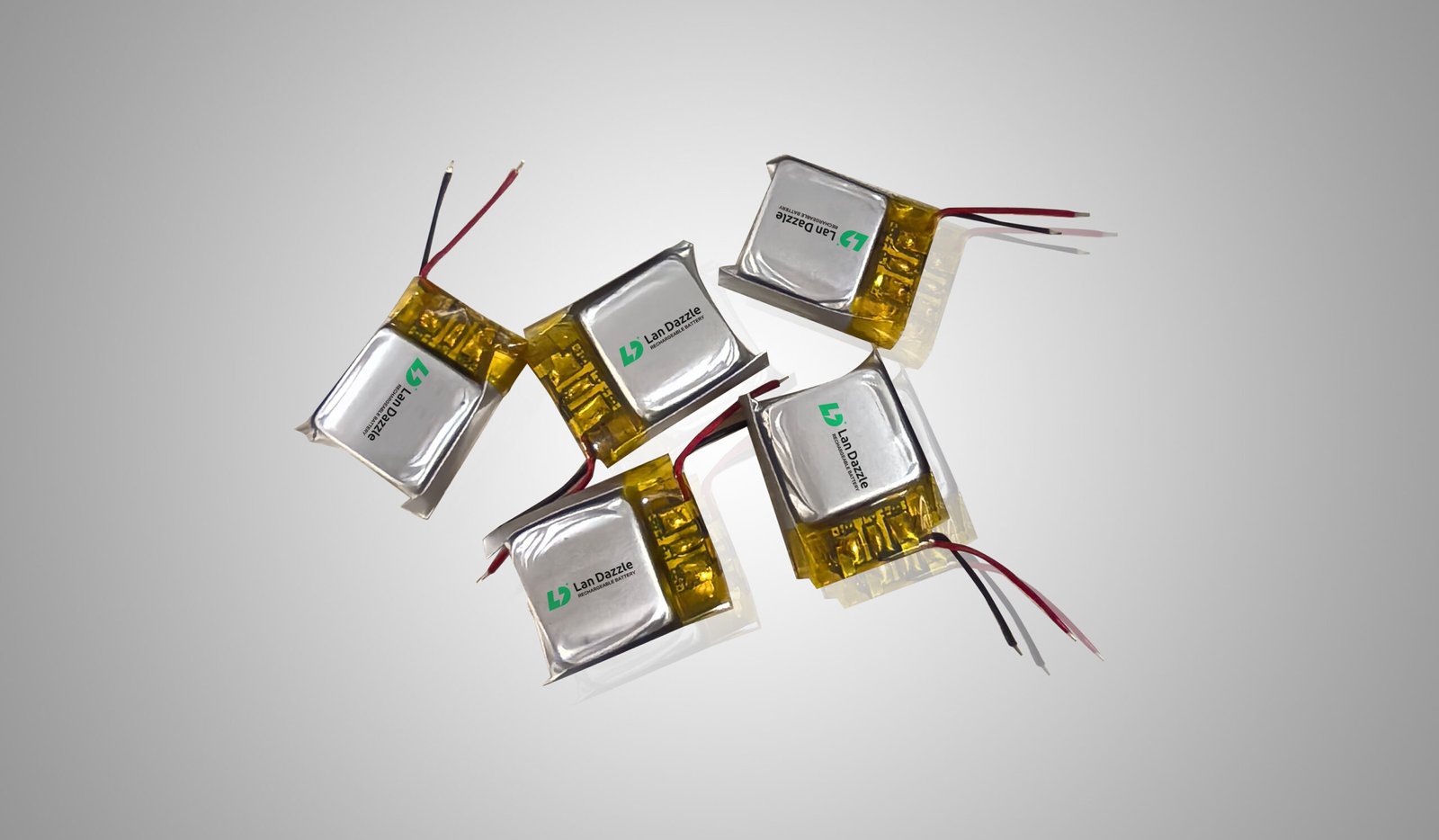

Given these intense, specific challenges, the solution must be equally specific. A custom-designed LiPo battery is not just a component; it is an integrated part of the device’s core design, engineered to solve the very problems of space, power delivery, and heat that plague standard cells.

The Custom LiPo Advantage: Form Factor Freedom

The single greatest advantage of Lithium-Polymer technology is its physical flexibility. Unlike rigid Lithium-Ion cells, which are confined to canned shapes, LiPo batteries use a gel-like electrolyte contained in a flexible pouch. This allows them to be manufactured in virtually any shape or size.

This is a game-changer for smart glasses designers. Instead of designing the glasses around the battery, they can design the battery to fit perfectly within the glasses. This means:

- Curved Batteries: Custom LiPo cells can be curved to follow the contour of the user’s head along the temple arms.

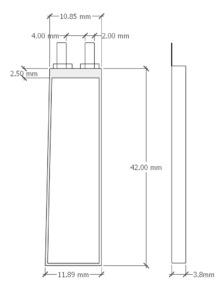

- Ultra-Thin Profiles: They can be made exceptionally thin to fit inside slender frames without adding bulk.

- Complex Shapes: They can be molded into L-shapes or other custom footprints to fill every available nook and cranny.

This “shape-shifting” ability ensures that no space is wasted. By maximizing the internal volume dedicated to the battery, a custom LiPo design can offer significantly more capacity (measured in milliampere-hours, or mAh) than a standard cell that would fit in the same device. This directly translates to longer runtime.

Tailored Performance: More Than Just Capacity

A custom LiPo battery is about more than just a perfect fit; its electrical characteristics can also be precisely engineered for the device’s needs.

- Optimized Discharge Rate (C-Rating): Smart glasses need to handle sudden spikes in power demand. A custom LiPo battery can be designed with a specific “C-Rating” that dictates how quickly it can safely discharge its energy. By matching the C-Rating to the peak demands of the processor and camera, the battery can deliver bursts of power without the voltage sagging, ensuring smooth, reliable performance.

- Lower Internal Resistance: Custom formulations and construction can lead to lower internal resistance, making the battery more efficient. This means less energy is wasted as heat and more is delivered to the components, further extending usable battery life.

Safety

Early LiPo batteries carried a reputation for being sensitive. However, modern, custom LiPo batteries designed for wearables are a world apart, incorporating multiple layers of safety and reliability, especially when paired with an intelligent Battery Management System (BMS). This crucial circuit, often integrated directly with the custom cell, provides protection against:

- Over-charging and over-discharging

- Excessive current draw

- High temperatures

- Short-circuits

This integrated safety system ensures that the battery operates within its ideal parameters, maximizing both its performance and its operational lifespan.

Enhancing the Custom LiPo Core

While the custom LiPo battery is the star of the show, it performs best as part of an integrated, holistic power strategy.

- Synergy with Power Management Systems: A sophisticated BMS does more than just protect the battery; it optimizes its performance. When a BMS is programmed with the precise characteristics of a custom LiPo cell, it can manage power delivery with incredible accuracy, squeezing every last drop of energy from the battery and providing the user with reliable “time remaining” estimates.

- Software and Cloud Offloading: Efficient software is crucial. Offloading heavy processing tasks to a connected smartphone or the cloud reduces the computational load on the glasses’ processor. This strategy perfectly complements a custom LiPo battery, as it lowers the overall power demand, allowing the custom-fit, high-capacity cell to last even longer.

- A Note on Future Tech: What about solid-state batteries? While promising, true solid-state technology for mass-market consumer electronics is still years away from being cost-effective and scalable. The principles of customization, however, will remain. The expertise being developed today in creating custom-shaped LiPo batteries will be directly applicable to designing and integrating these future technologies when they mature. For now and the foreseeable future, custom LiPo remains the superior choice.

Conclusion

Designing batteries for smart glasses demands solving a dozen interlinked challenges—from millimeter‑thin profiles and high‑power draws to strict safety and charging expectations. Off‑the‑shelf cells simply can’t hit these marks. By leveraging bespoke pouch‑cell geometries, cutting‑edge materials, and integrated BMS intelligence, Lan Dazzle empowers OEMs to deliver truly wearable, reliable, and high‑performance smart glasses. Ready to see how our custom micro‑battery solutions can transform your next wearable project? Contact our team at info@landazzle.com or request a prototype today.