The hum of innovation in the motorcycle and powersports industries is growing louder, driven significantly by advancements in connectivity and safety. At the forefront of this evolution are Bluetooth-enabled helmets, transforming the riding experience with seamless communication, GPS navigation, music streaming, and increasingly, integrated safety features like incident detection. For manufacturers, keeping pace with this rapid technological curve isn’t just about integrating more features; it’s fundamentally about powering innovation. The lifeblood of every cutting-edge Bluetooth helmet is its battery system, and for a product that demands both performance and safety in extreme environments, off-the-shelf solutions often fall short.

This comprehensive guide delves into the intricate world of battery solutions for Bluetooth helmets, specifically tailored for manufacturers. We’ll explore the unique challenges of powering these devices, dissect various battery technologies, make a compelling case for custom helmet battery design, and outline the critical factors for choosing the right manufacturing partner. Our goal is to equip you with the knowledge to not only meet but exceed consumer expectations for reliable, long-lasting, and safe helmet power.

The Growing Demand for Reliable Power in Bluetooth Helmets

Modern Bluetooth helmets are far more than just protective gear; they are sophisticated communication hubs and entertainment systems on two wheels. Riders today expect seamless, high-fidelity audio for intercom conversations, crystal-clear instructions from GPS, and uninterrupted music for long journeys. Beyond these core functionalities, advanced models are integrating features like noise cancellation, mesh communication networks, ambient sound pass-through, and even emergency alert systems. Each additional feature, while enhancing the rider’s experience, places an increased demand on the helmet’s power source.

This escalating sophistication directly correlates with the need for efficient and long-lasting power. As the market for Bluetooth helmets continues its upward trajectory – with projections consistently showing steady growth driven by technological adoption and increased global motorcycle ownership – consumer expectations for battery life and reliability have become paramount. A Bluetooth helmet that dies halfway through a ride is not just an inconvenience; it can compromise safety and communication, leading to significant user frustration and negative brand perception. Manufacturers must therefore view the battery not as an afterthought, but as a core component critical to both functionality and user satisfaction.

Understanding the Unique Challenges of Helmet Battery Design

Designing power solutions for Bluetooth helmets presents a distinctive set of engineering challenges that go far beyond typical consumer electronics. The very nature of a helmet imposes stringent constraints:

- Size, Weight, and Shape: Helmets are ergonomically designed to be compact, lightweight, and aerodynamic. Integrating a battery without compromising these factors is a delicate balancing act. Every millimeter and gram counts, requiring highly energy-dense and custom-shaped cells that can fit into irregular voids within the helmet structure.

- Safety Standards and Regulations: Given that helmets are safety devices, their integrated electronics and batteries are subject to rigorous safety standards. This includes resistance to impact, vibration, and extreme temperatures. Preventing thermal runaway, managing heat dissipation, and ensuring protection against overcharge/discharge are non-negotiable. Compliance with international standards like UN 38.3 for lithium battery transport and specific regional certifications is crucial for global market access. Battery failures in wearable devices, even minor ones, can lead to product recalls and severe reputational damage.

- Environmental Factors: Motorcycle helmets operate in a diverse and often harsh environment. Batteries must withstand significant temperature variations (from freezing cold to intense heat), exposure to moisture, dust, and constant vibration from the motorcycle itself. This demands robust battery packs with superior sealing, durable casings, and integrated thermal management systems.

- User-Friendly Charging and Indicators: Beyond the battery itself, the entire power ecosystem must be user-centric. This includes intuitive charging ports, fast-charging capabilities, and accurate battery level indicators that are easily visible or audibly communicated to the rider. The charging solution must also be robust enough to withstand outdoor conditions.

These complex requirements underscore why a generic, off-the-shelf battery often falls short. A truly effective helmet battery system must be engineered with these specific operational conditions and design constraints in mind.

Exploring Different Battery Technologies for Bluetooth Helmets

The choice of battery chemistry is foundational to a helmet’s performance, safety, and lifespan. While the landscape of battery technology is constantly evolving, several key chemistries are currently relevant for Bluetooth helmet applications:

- Lithium-ion (Li-ion): This is the most prevalent battery technology in modern portable electronics, including many Bluetooth helmets.

- Pros: High energy density (meaning more power in a smaller package), relatively low self-discharge rate, and no memory effect.

- Cons: Can be susceptible to thermal runaway if poorly managed or damaged, requiring sophisticated Battery Management Systems (BMS) for safety.

- Typical Energy Density: 150-250 Wh/kg.

- Cycle Life: Generally 300-500 charge/discharge cycles before significant capacity degradation.

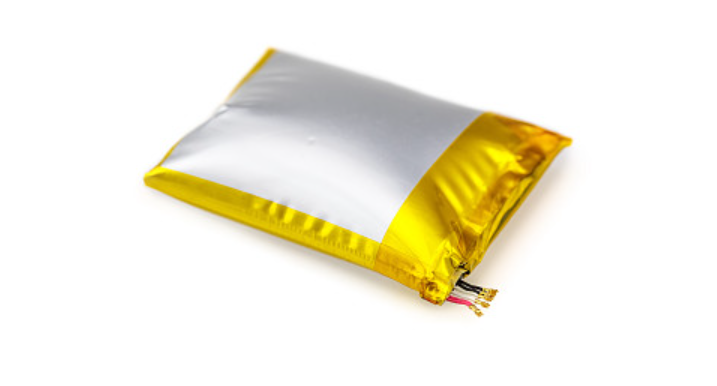

- Lithium-polymer (Li-Po): A variant of Li-ion, often favored for its flexible form factor.

- Pros: Can be manufactured in very thin, flexible, and custom shapes, making them ideal for integration into the irregular spaces within a helmet. Similar energy density to Li-ion.

- Cons: Similar safety concerns to Li-ion, requiring careful handling and robust protection circuits. Potentially less durable against punctures than cylindrical Li-ion cells.

- Typical Energy Density: Similar to Li-ion, 150-250 Wh/kg.

- Cycle Life: Similar to Li-ion.

- Emerging Technologies (e.g., Solid-state Batteries): While not yet widely commercialized for small consumer electronics, solid-state batteries are a promising future technology.

- Pros: Potentially higher energy density, improved safety (non-flammable solid electrolyte), faster charging, and longer cycle life.

- Cons: Still in early stages of mass production, higher manufacturing costs, and potential challenges with extreme temperature performance.

- Relevance for Helmets: Could allow for significantly lighter, smaller, and safer power solutions in the future.

For most current Bluetooth helmets, Li-ion and especially Li-Po batteries offer the best balance of energy density, cost, and form factor flexibility. However, understanding the nuances of each and continually monitoring advancements is crucial for future-proofing your product line.

The Case for Custom Battery Solutions for Manufacturers

In an increasingly competitive market, relying on generic, off-the-shelf battery packs can severely limit your product’s potential. For manufacturers aiming to differentiate their Bluetooth helmets, a custom battery solution is not just an option; it’s a strategic imperative.

Here’s why tailoring your battery solution makes a significant difference:

- Optimized Shape and Size: Helmets have unique internal geometries. A custom battery can be designed to perfectly fit available spaces, maximizing capacity without compromising aesthetics, ventilation, or structural integrity. This allows for sleeker designs and better weight distribution, enhancing rider comfort.

- Tailored Capacity and Discharge Rates: Different helmet models offer varying feature sets and power demands. A custom battery allows you to specify the exact capacity (mAh) needed to meet target runtimes and ensure the battery can reliably deliver the necessary current for power-intensive features (e.g., high-volume audio, active noise cancellation) without performance degradation.

- Integrated Safety Features: While off-the-shelf packs have basic protection, a custom solution allows for the integration of advanced safety features directly into the battery pack design. This includes custom-tuned Battery Management Systems (BMS) for precise overcharge, over-discharge, overcurrent, and thermal protection specific to the helmet’s operating conditions. This proactive approach to safety significantly reduces risk and enhances product reliability.

- Enhanced Performance and Longevity: By designing the battery to the specific load profile of the helmet, you can optimize its performance and extend its overall lifespan. This means more consistent power delivery, reduced degradation over time, and ultimately, a more reliable product for the end-user.

- Cost-Effectiveness in the Long Run: While the initial tooling for a custom battery might be higher, the long-term benefits often outweigh this. Optimized design reduces material waste, allows for more efficient assembly processes, and minimizes warranty claims due to battery failures. Furthermore, a perfectly integrated custom battery can eliminate the need for costly redesigns or compromises down the line. A hypothetical scenario might involve a manufacturer integrating a new, power-hungry mesh communication module. Without a custom battery, they might have to sacrifice battery life or make the helmet bulkier. With a custom battery designed for the specific power profile and available space, they can seamlessly integrate the new feature without compromising other aspects of the helmet.

- Branding and Differentiation: A custom battery, even if internal, speaks volumes about a manufacturer’s commitment to quality and innovation. It reflects a holistic design philosophy where every component is optimized for the best possible user experience.

Investing in a custom battery solution is an investment in your product’s core performance, safety, and market differentiation.

Key Considerations When Choosing a Custom Battery Partner

Selecting the right partner for your custom helmet battery solutions is a critical decision that impacts product quality, safety, and your time-to-market. It’s not just about finding a supplier, but a true technological collaborator.

Here are the key factors to consider:

- Experience and Expertise: Look for a partner with a proven track record in designing and manufacturing small, high-performance batteries for demanding applications, particularly in wearable technology or rugged environments. Their engineering team should understand the nuances of integrating power into compact, safety-critical devices.

- Quality Control and Certifications: The partner must demonstrate stringent quality control processes at every stage, from cell sourcing to final pack assembly. Verify their adherence to international quality management standards (e.g., ISO 9001) and their ability to provide batteries that meet relevant safety certifications (e.g., UL, CE, UN 38.3). In 2023 alone, there were numerous product recalls related to battery safety, highlighting the absolute necessity of robust quality assurance.

- Design and Engineering Support: A valuable partner offers more than just manufacturing; they provide comprehensive design and engineering support. This includes assistance with cell selection, BMS design, mechanical housing design, prototyping, and rigorous testing tailored to your specific helmet application. They should be able to co-develop solutions that perfectly integrate with your helmet’s form factor and power requirements.

- Production Capacity and Scalability: Ensure the partner can meet your production volume requirements, both for initial runs and for scaling up as demand grows. Discuss lead times, production capabilities, and their supply chain resilience to avoid disruptions.

- Testing and Validation Capabilities: A reputable partner will have in-house testing facilities for performance validation (capacity, discharge rates, cycle life) and safety testing (short circuit, overcharge, crush, impact, thermal cycling). This ensures the batteries are robust enough for the harsh realities of helmet use.

- After-Sales Support and Warranty: Understand their policy on warranty, technical support, and troubleshooting. A strong partnership extends beyond delivery of the product.

By thoroughly vetting potential partners against these criteria, you can secure a collaboration that yields reliable, safe, and high-performance battery solutions, ultimately enhancing your brand’s reputation and product success.

Conclusion

As Bluetooth helmets continue to evolve, integrating more sophisticated features and demanding longer runtimes, the significance of a robust and reliable power source cannot be overstated. For manufacturers, the path to innovation and market leadership lies not in generic power solutions, but in understanding and leveraging the advantages of custom battery solutions for Bluetooth helmets.

By embracing tailored battery designs, you can optimize for critical factors like size, weight, safety, and performance, directly addressing the unique challenges of helmet integration. Partnering with an experienced and quality-focused battery manufacturer allows you to transform these power systems from a mere component into a strategic differentiator, ensuring your products deliver the seamless, long-lasting, and safe experiences modern riders demand. The future of rider communication and safety is powered by intelligent design, and at its core lies the perfectly engineered battery.

Looking for a Custom Battery Solution for Your Bluetooth Helmet Project?

At Lan Dazzle, we specialize in designing and manufacturing custom lithium polymer batteries tailored to your device’s unique size, shape, and power requirements. Whether you need a slim profile, high energy density, or integrated protection circuits—we’ve got you covered.

👉 Contact us today at info@landazzle.com to develop a battery solution that fits your helmet perfectly.