Lithium-Ionen-Batterien have become the ubiquitous power source of our modern era, fueling everything from handheld devices to electric vehicles and large-scale energy storage systems. The demand for higher energy density, improved safety, and cost-effective production continues to drive innovation in battery technology and manufacturing processes. Among the critical steps in producing a Li-ion battery is the assembly of the cell, where the electrodes and separator are brought together. Two primary methods dominate this stage: winding vs stacking. Each approach has its own set of advantages and disadvantages, making the choice between them a crucial decision for battery manufacturers.

This article delves into a comprehensive comparison of li-ion battery winding and stacking, exploring their fundamental processes, key differences in performance characteristics, suitability for various applications, and future trends. Understanding these nuances is essential for engineers and manufacturers aiming to optimize battery design and production for specific needs, particularly in the rapidly growing electric vehicle (EV) sector.

Understanding Li-ion Battery Cell Assembly

Before comparing the two methods, it’s crucial to understand the basics of each process.

The Winding Process

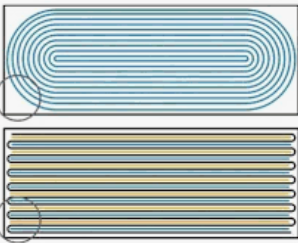

The winding process involves taking long sheets of the anode, separator, and cathode and rolling them together tightly in a spiral form, often referred to as a “jelly roll.” This continuous rolling creates alternating layers of the electrode materials separated by the insulator. The resulting roll is then typically flattened or inserted into a cylindrical or prismatic casing.

- Key materials: Anode (e.g., graphite, silicon composite), cathode (e.g., NMC, NCA, LFP), and a porous separator.

- Typical cell formats: Predominantly cylindrical cells (like the 18650, 2170, 4680 formats) and some prismatic cells.

Think of it like rolling up a sandwich with alternating layers. This method is known for its high-speed and relatively straightforward automation.

The Stacking Process (Lamination)

In contrast, the stacking process, also known as lamination, involves layering individual cut sheets of the anode, separator, and cathode on top of each other. This layer-by-layer assembly can create prismatic or pouch cell formats. Tabs are then connected to the respective electrode layers.

- Key materials: Similar to winding: anode, cathode, and separator, but processed into individual sheets.

- Typical cell formats: Primarily pouch cells and some prismatic cells.

Imagine stacking individual pieces of paper with insulating sheets in between. While potentially more complex in terms of handling individual components, stacking offers unique advantages in terms of space utilization and design flexibility.

The Key Differences: Winding vs Stacking

The choice between winding and stacking significantly impacts the final battery cell’s characteristics. Let’s explore the key differences:

Energy Density and Space Utilization

- Winding: While efficient for cylindrical formats, the rounded nature can lead to less optimal use of space, particularly in rectangular or prismatic casings, leaving unused corner areas.

- Stacking: Excels in space utilization, especially in prismatic and pouch formats. The layered structure allows for a more complete filling of the rectangular volume, leading to potentially higher volumetric energy density.

For applications where maximizing energy within a given volume is critical, such as high-performance EVs, stacking presents a notable advantage.

Internal Resistance and Performance

- Winding: Typically involves fewer tabs connecting the electrodes, which can lead to longer electron pathways and thus slightly higher internal resistance.

- Stacking: Facilitates the use of multiple tabs connected to different layers, effectively shortening the electron transport distance and lowering internal resistance. This lower resistance translates to better high-rate performance (faster charging and discharging) and reduced heat generation.

Stacking can lower internal resistance by 10-15% compared to winding, contributing to improved power delivery and thermal management.

This makes stacking particularly attractive for applications demanding high power output, like electric vehicle acceleration.

Lebensdauer und Langlebigkeit im Zyklus

- Winding: The mechanical stresses during the winding process and the expansion/contraction of electrode materials during cycling can lead to stress concentrations, particularly at the corners of the wound jelly roll.

- Stacking: The layered structure generally results in a more uniform distribution of stress during material expansion and contraction, potentially leading to improved cycle life and durability. The absence of tight bends as in winding can reduce mechanical degradation.

While specific data varies with cell design and materials, the principle of more even stress distribution in stacked cells often correlates with longer lifespan.

Sicherheit

- Winding: The tight winding can sometimes lead to internal shorts if there are defects in the separator or due to mechanical stress causing layers to come into contact, especially at the bent edges.

- Stacking: While lamination requires precise alignment to avoid shorts between layers, the more controlled layering and the potential for incorporating more robust separators between layers can contribute to enhanced safety. The even pressure distribution also reduces the risk of localized stress leading to separator failure.

The “C-corner” in wound batteries has historically been a point of concern regarding potential short circuits.

Manufacturing Efficiency and Cost

- Winding: Generally considered a faster and more mature process with high throughput and potentially lower initial equipment investment for certain formats like cylindrical cells. Production efficiency can reach >12 parts per minute.

- Stacking: Historically, stacking has been slower and more complex due to the handling of individual sheets. However, advancements in automation are improving its efficiency (currently around 6-8 parts per minute). The initial investment for high-precision stacking equipment can be higher.

For high-volume production of smaller, cylindrical cells, winding often holds a cost advantage. However, for pouch and larger prismatic cells requiring high energy density, the benefits of stacking can outweigh the potentially higher manufacturing costs.

Thermisches Management

- Winding: Heat dissipation can be less uniform due to the tightly wound structure.

- Stacking: The layered structure of stacked cells often allows for more efficient and uniform heat dissipation, especially in pouch formats where the flat surfaces facilitate better contact with cooling systems. Temperature variation in stacked cells under high-rate discharge can be significantly lower compared to wound cells.

Effective thermal management is crucial for battery life, performance, and safety, making stacking advantageous in high-power applications.

Applications: Where Each Method Excels

The distinct characteristics of wound and stacked batteries make them suitable for different applications:

- Winding: Commonly found in consumer electronics (laptops, power tools) and in some cost-sensitive or standardized format EV battery packs (often using cylindrical cells). The mature manufacturing process and cost-effectiveness for certain formats are key advantages here.

- Stacking: Increasingly preferred for high-performance electric vehicles and energy storage systems where maximizing energy density, achieving high power output, and superior thermal management are critical. Pouch cells, typically manufactured using stacking, are prevalent in many modern EVs.

For instance, while many early EVs utilized cylindrical, wound cells, newer high-performance models often employ pouch cells made using stacking technology to achieve greater range and power.

The Future Trends

Both winding and stacking technologies are continuously evolving. Advancements in high-speed winding for prismatic cells and improvements in the speed and precision of stacking processes are blurring the lines. There’s also a growing interest in hybrid approaches and innovative cell designs that might incorporate elements of both methods. Integrated winding and lamination machines are being developed to combine the benefits of both techniques. The trend towards higher energy density and safer batteries will likely continue to favor advancements in stacking for certain high-demand applications.

Fazit

The choice between winding and stacking for lithium-ion battery cell assembly is not a matter of one being universally superior to the other. Instead, it hinges on a trade-off between factors like energy density, power performance, safety, manufacturing cost, and the specific requirements of the application. While winding remains a cost-effective and efficient method for many applications, stacking is gaining prominence, particularly in the electric vehicle and energy storage sectors, where its advantages in energy density, thermal management, and performance are highly valued. As battery technology continues to advance, we may see further innovations that leverage the strengths of both approaches.

FAQ

- What is the main difference between li-ion battery winding and stacking?

- Winding involves rolling the electrode and separator layers into a spiral (jelly roll), while stacking involves layering individual sheets on top of each other.

- Which method, winding or stacking, offers higher energy density?

- Generally, stacking can offer higher volumetric energy density due to better space utilization, especially in prismatic and pouch formats.

- Is one method safer than the other for li-ion batteries?

- Both have safety considerations. Stacking’s more uniform stress distribution can be advantageous, while winding has potential risks at the bends. Advanced designs and manufacturing processes in both methods aim to maximize safety.

- Which manufacturing process, winding or stacking, is more cost-effective?

- Winding is often more cost-effective for high-volume production of cylindrical cells due to its speed and mature automation. However, this can vary depending on the cell format and required performance.

- For electric vehicles, are wound or stacked batteries preferred?

- While early EVs used wound cylindrical cells, there’s a growing trend towards stacked pouch and prismatic cells in high-performance EVs due to their higher energy density and better thermal management.

- What are the advantages of stacked batteries over wound batteries?

- Advantages of stacked batteries often include higher energy density, lower internal resistance (leading to better power performance), potentially longer cycle life due to more uniform stress, and better thermal management.