Einführung

Agricultural drones have transformed modern farming, enabling precision spraying, crop monitoring, and field mapping with unprecedented efficiency. However, one critical component continues to limit their full potential: agricultural drone batteries. Despite advances in drone technology, many agricultural drones still rely on power systems that struggle with endurance, environmental resilience, and operational reliability.

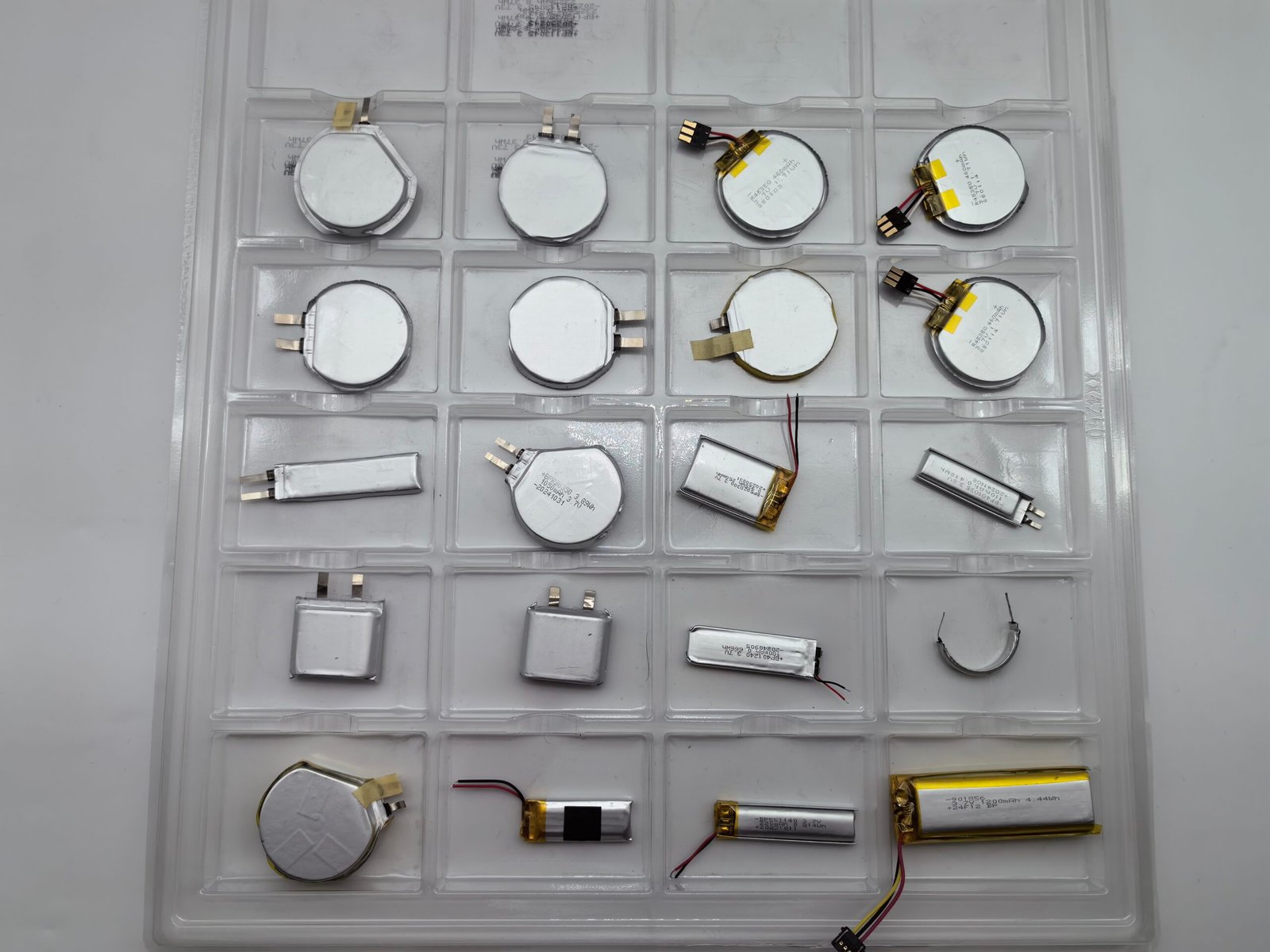

Unter Lan DazzleWir sind spezialisiert auf die Entwicklung und Herstellung von Kundenspezifische Lithium-Batterielösungen that directly address the unique challenges facing agricultural drone users. From maximizing flight time to enhancing safety and cold-weather performance, our batteries are engineered for demanding agricultural environments.

1. Challenges in Agricultural Drone Batteries

⏱️ Short Flight Time Limits Efficiency

Most agricultural drones can only fly for 15 to 30 minutes on a single charge, making them inefficient for large-scale farmland operations. Increased battery capacity often means heavier weight, which reduces flight time and load capacity — creating a delicate trade-off between energy and efficiency.

🔌 Long Charging Times Disrupt Workflow

Traditional drone batteries require hours to recharge, forcing operators to either carry multiple battery packs or pause operations, which is particularly problematic during peak farming seasons.

❄️☀️ Temperature Extremes Affect Battery Performance

Agricultural drones are exposed to a variety of climates:

-

In hot environments, battery overheating can cause degradation or even safety hazards.

-

In cold weather, typical lithium batteries suffer from reduced discharge rates and may not function at all.

♻️ Short Battery Lifespan Increases Long-Term Costs

Standard drone batteries usually offer only 200–500 charge cycles. For agricultural service providers who operate daily, this translates into frequent replacements and rising operational costs.

⚠️ Safety Risks Due to High Power Demand

Agricultural drones often require high power outputs to carry payloads and operate precision equipment. Poor-quality batteries may swell, overheat, or fail catastrophically under pressure.

📉 Lack of Smart Battery Management

Many batteries on the market lack integrated Battery Management Systems (BMS), preventing real-time monitoring of voltage, temperature, and charge status — all crucial for reliability and safety.

2. Lan Dazzle’s Custom Battery Solutions for Agricultural Drones

Unter Lan Dazzle, we tackle these problems head-on by offering customized lithium-ion battery packs specifically engineered for agricultural drone applications.

✅ High Energy Density, Lightweight Design

Our batteries are built with high-capacity lithium cells while maintaining low weight, allowing drones to fly longer and carry more without compromising flight dynamics.

⚡ Fast Charging and Modular Swapping

We design battery packs compatible with fast-charging protocols and modular plug-in designs, enabling quick battery changes in the field to reduce downtime.

❄️🔥 Breiter Betriebstemperaturbereich

Using advanced electrolyte formulations and thermal-resistant materials, our batteries operate reliably in -20°C bis 60°C environments — ideal for all-season agricultural use.

🧠 Intelligent Battery Management System (BMS)

Lan Dazzle can help custom battery management system according to customers’ needs:

-

Overcharge/overdischarge protection

-

Short-circuit and thermal protection

-

Real-time health monitoring

-

Remaining capacity prediction

♻️ Extended Lifespan

Our packs support over 500 Ladezyklen, significantly reducing long-term costs and waste, and offering greater ROI for farmers and service providers.

🛠️ Full Customization Options

From voltage, capacity, and discharge rates zu shape, casing, and connector types, we offer full customization to match the specifications of your drone models and agricultural missions.

3. Real-World Use Cases

🌾 Large-Scale Crop Spraying

Our high-capacity batteries power drones that spray hectares of crops in a single flight, increasing productivity and reducing chemical waste.

🍎 Orchard Management

Custom low-temperature batteries ensure reliable drone operations in early mornings or during cold seasons for fruit spraying and health assessments.

🛰️ Aerial Mapping and Monitoring

Precision farming requires long flight durations for mapping — our lightweight, high-energy solutions make long-range monitoring more practical and cost-effective.

4. Why Choose Lan Dazzle?

Lan Dazzle is a professional battery manufacturer with deep expertise in custom lithium battery development for drones, robots, wearables, and smart tools. Here’s why agricultural drone manufacturers and operators trust us:

-

🔧 Dedicated Custom Engineering Team

-

🧪 Strict Quality Control and Environmental Testing

-

🚀 Fast Prototyping and Scalable Production

-

🌍 Worldwide Support and Logistics

-

🔋 End-to-End Battery Solutions – from cell to pack

5. Contact Us

Looking to improve your agricultural drone performance with advanced battery technology? We’re here to help.

🌐 Website: www.landazzle.com

📧 Email: info@landazzle.com

Fazit

The future of precision agriculture depends on drones — and drones depend on reliable, efficient, and intelligent battery systems. At Lan Dazzle, we’re committed to powering that future through custom-engineered battery solutions that address the real challenges of agricultural drone operations.

Don’t settle for generic batteries. Choose Lan Dazzle for smarter energy in the sky — custom-built for your field, your drone, and your success.