Índice

¿Alguna vez ha tenido problemas para encontrar una batería que realmente se adapte a su dispositivo exclusivo? Puede que el modelo que necesita esté descatalogado. Puede que el diseño de su producto sea tan especial que una pila estándar no encaje. O tal vez trabaja en un espacio tan reducido que cada milímetro es importante.

Estas frustraciones son demasiado comunes. El mercado está inundado de baterías estándar, pero cuando se trata de tamaños irregulares o requisitos especializados, la mayoría de los proveedores se detienen en "una talla para todos". Esto hace que los innovadores como usted se enfrenten a retrasos, rediseños o compromisos costosos.

Aquí es exactamente donde LanDazzle marca la diferencia. No nos limitamos a vender baterías: creamos soluciones adaptadas a su visión.

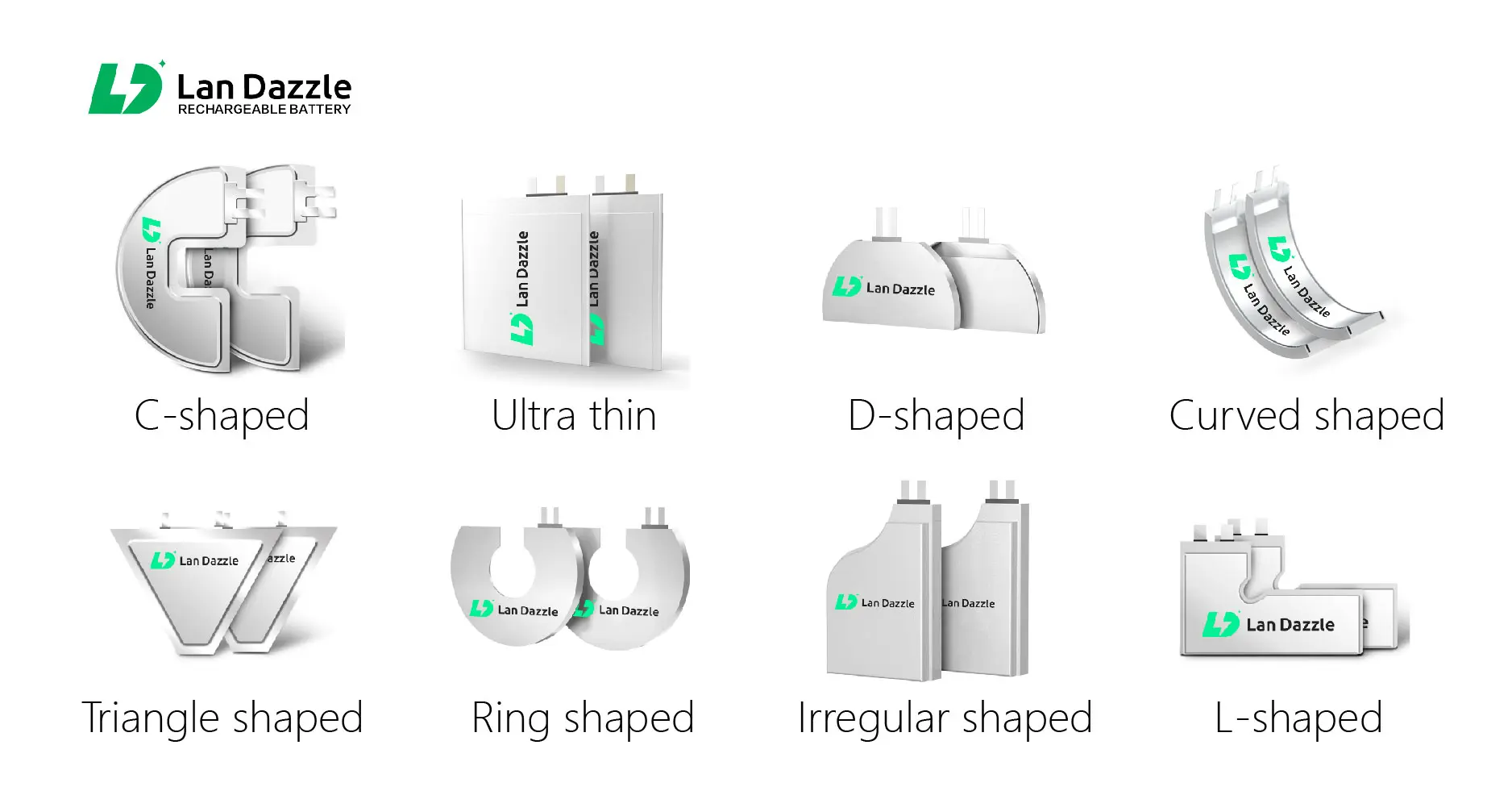

Algunas pilas de tamaño irregular

Batería LanDazzle de forma irregular: Diseñada a su medida

Olvídese de las limitaciones de las baterías estándar. Nuestra especialidad es crear soluciones de alimentación que se adapten a la forma y función únicas de tu dispositivo, no al revés.

Nuestros rasgos distintivos:

1. Factor de verdadera forma personalizada

No nos limitamos a doblar tamaños estándar; diseñamos desde cero. Facilítenos el modelo 3D o las dimensiones exactas de su dispositivo y le entregaremos una batería que se ajuste con precisión milimétrica, ya sea una forma curvada en L, un polígono compacto o una funda ultrafina.

- Su beneficio: Elimine el espacio desaprovechado, permita diseños de productos elegantes y resuelva para siempre el problema del "casi cabe".

2. Ajuste del rendimiento específico de la aplicación

Un dispositivo médico tiene necesidades energéticas diferentes a las de un juguete de alto consumo. No creemos en un perfil de rendimiento único. Adaptamos el voltaje, la capacidad (mAh) y la tasa de descarga (tasa C) para satisfacer las demandas exactas de su aplicación.

3. Soluciones de conectores e interfaces a medida

La conexión es tan crítica como la célula. Personalizamos las interfaces físicas y de comunicación para garantizar una integración perfecta. Esto incluye cables de longitud personalizada, conectores específicos (JST, Molex, etc.), pestañas soldadas o incluso la integración de protocolos inteligentes SMBus/I2C.

- Su beneficio: Una auténtica experiencia "plug-and-play". Se acabaron los problemas de cableado y compatibilidad, solo conectividad fiable y segura.

4. Seguridad integrada y gestión inteligente

Todas las baterías personalizadas incorporan un sistema de gestión de baterías (BMS) o circuito de protección a medida. Lo programamos para sus necesidades específicas -protección contra sobrecargas, control de la temperatura y prevención de cortocircuitos- utilizando celdas de Li-Po o Li-Ion de alta calidad que cumplen las normas de seguridad internacionales.

5. Recargabilidad de alto rendimiento

Apueste por la sostenibilidad y el ahorro de costes. Nuestras baterías personalizadas se fabrican con celdas recargables de alta vida útil. Nos aseguramos de que la química y el algoritmo de carga estén perfectamente adaptados para una durabilidad a largo plazo.

Casos prácticos: Soluciones probadas de baterías personalizadas

Las historias de éxito reales hablan más alto que las promesas. A continuación presentamos cuatro proyectos que muestran cómo LanDazzle convierte ideas desafiantes en soluciones energéticas fiables y personalizadas.

Caso 1: Batería ultrafina para tarjetas inteligentes de nueva generación

- Cliente / Sector

Un fabricante mundial de tarjetas inteligentes desarrolla una nueva generación de tarjetas de identidad con sensores. - Desafío

- El grosor total debía ser inferior a 1 mm para cumplir las normas internacionales sobre tarjetas.

- Requería una salida estable de 3,7 V y un ciclo de vida largo en un perfil fino como el papel.

- La batería necesitaba suficiente resistencia mecánica para sobrevivir a la flexión y la laminación.

- Nuestra solución

- Se ha diseñado una célula LiPo de alta densidad energética utilizando materiales avanzados para el cátodo y el ánodo de silicio-carbono.

- Adoptó un arquitectura de capas apiladas en lugar del bobinado tradicional para minimizar el grosor.

- Se ha seleccionado una funda de polímero de aluminio de primera calidad para mayor durabilidad y baja resistencia interna.

- Resultado

Entregado un 1 mm de grosor, 155 mAh que pesa sólo 3,6 g y mantiene su rendimiento tras más de 500 ciclos.

El cliente lanzó la tarjeta sin rediseñar su electrónica, ahorrando meses de tiempo de desarrollo.

Caso 2: Batería LiPo curva para anillos inteligentes

- Cliente / Sector

Una empresa de tecnología para llevar puesta crea un anillo inteligente de seguimiento de la salud. - Desafío

- El espacio interior era tan reducido que cada fracción de milímetro contaba.

- La célula debía seguir la curva interior del anillo para que encajara a la perfección.

- La seguridad era fundamental para el contacto continuo con la piel.

- Nuestra solución

- Usado Escaneado y modelado 3D para diseñar una célula LiPo curva que se ajustara a la geometría del anillo.

- Se mantiene el grosor en unos 1,7 mm al tiempo que se integra un circuito de protección en miniatura.

- Emplea una película ultrafina de polímero de aluminio para mayor flexibilidad y estabilidad.

- Resultado

Producido un 22 mm x 1,8 mm, 17 mAh batería personalizada que pesa sólo 0,5 g y funciona con seguridad de -20 °C a 60 °C.

El cliente consiguió energía para todo el día en un diseño elegante sin alterar el factor de forma del anillo.

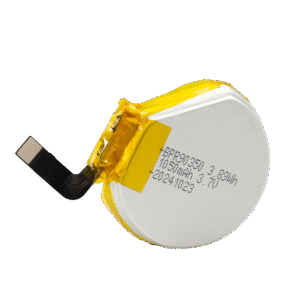

Caso 3: La batería redonda maximiza el espacio del smartwatch

- Cliente / Sector

Una marca líder de relojes inteligentes que busca una mayor autonomía sin cambiar su diseño principal. - Desafío

- Las células prismáticas estándar desperdiciaban un valioso espacio interno en la carcasa circular del reloj.

- Necesitaba mayor capacidad sin perder su perfil delgado.

- Nuestra solución

- Desarrollado un batería LiPo redonda personalizada para adaptarse perfectamente al interior curvado del reloj.

- Estratificación optimizada de los electrodos y sellado de la bolsa para aumentar la densidad energética.

- Resultado

El reloj ganó aumentos significativos de capacidad y una mayor duración de la batería sin rediseñar la placa de circuito impreso ni la carcasa, lo que reduce los costes y acelera la comercialización.

Caso 4: Pack de alta capacidad para robots de educación infantil

- Cliente / Sector

Una empresa de robótica que construye robots interactivos de aprendizaje para niños. - Desafío

- Poca batería, pero grandes requisitos de potencia para motores, sensores y procesamiento de inteligencia artificial.

- Necesitaba más tiempo de funcionamiento entre cargas para mantener a los niños ocupados.

- Nuestra solución

- Diseñado un Batería de polímero de iones de litio de forma irregular con circuito de protección integrado.

- Aumento de la capacidad en más de 20 % a la vez que encaja perfectamente en la estrecha esquina de la carcasa.

- Resultado

Los robots funcionan ahora notablemente más tiempo con una sola carga, lo que mejora la experiencia del usuario y reduce el mantenimiento de las escuelas.

Preguntas frecuentes sobre pilas con forma personalizada

P1: ¿Qué información debo facilitar para empezar?

Cuanta más información pueda compartir, más precisa será nuestra propuesta inicial. Principalmente necesitamos:

- Dimensiones físicas: Lo ideal es un modelo 3D (STEP, IGES) o dibujos detallados. Como alternativa, se pueden utilizar mediciones precisas (LWT) y una foto del espacio de la batería también funcionan.

- Especificaciones eléctricas: Tensión, capacidad (mAh) y corriente continua/de descarga requeridas.

- Interfaz/Conector: Una foto o el número de modelo del conector que utilizas.

- Aplicación: ¿Para qué dispositivo es? Conocer el uso final (por ejemplo, médico, industrial, electrónica de consumo) nos ayuda a recomendar la química celular más segura y fiable.

P2: ¿Cuál es la cantidad mínima de pedido (MOQ) habitual para las baterías personalizadas?

Estamos orgullosos de nuestra flexibilidad. Aunque la rentabilidad mejora con el volumen, nosotros satisfacer una amplia gama de necesidades, desde muestras prototipo hasta producción en serie. Nuestro MOQ puede ser tan bajo como 50-100 unidades para muchos proyectos. Póngase en contacto con nosotros con sus datos y encontraremos una solución que se adapte a su escala.

P3: ¿Cuánto dura todo el proceso de desarrollo de una batería personalizada?

El calendario depende de la complejidad del proyecto, pero suele seguir las siguientes etapas:

- Presupuesto y propuesta: 1-3 días laborables después de recibir sus requisitos.

- Desarrollo de muestras: De 4 a 6 semanas (incluye diseño, aprovisionamiento y montaje).

- Producción: De 3 a 5 semanas tras la aprobación de la muestra.

Siempre damos prioridad a una comunicación clara y proporcionaremos un calendario detallado del proyecto tras la confirmación del pedido.

P4: ¿Pueden ayudarme si no tengo todas las especificaciones técnicas, sólo un dispositivo y un problema?

Sí que podemos. Muchos de nuestros clientes acuden a nosotros exactamente con esta situación. Empiece por hablarnos de su dispositivo y del problema al que se enfrenta (por ejemplo, "la batería no encaja", "se agota demasiado rápido"). Nuestros ingenieros trabajarán con usted en la ingeniería inversa de la solución, lo que puede implicar analizar su antigua batería o el propio dispositivo.

P5: ¿Son recargables sus pilas personalizadas?

La gran mayoría lo son. Estamos especializados en baterías recargables de polímero de litio (Li-Po) y de iones de litio (Li-Ion) personalizadas, ya que ofrecen el mejor valor y flexibilidad para formas únicas. Si su aplicación requiere estrictamente un producto químico no recargable (primario), también podemos estudiarlo.

P6: ¿Qué certificaciones e informes de pruebas pueden facilitar?

Como fabricante profesional de baterías, damos prioridad a la seguridad y el cumplimiento de la normativa. Los certificados específicos dependen de los requisitos de su proyecto y del mercado de destino. Proporcionamos habitualmente:

- Certificaciones estándar: Sostenemos Sistema de gestión de la calidad ISO 9001 garantizando procesos de producción coherentes y fiables.

- Certificaciones a nivel celular: Nos abastecemos de células que vienen con UL, IEC 62133 o UN38.3 certificaciones, fundamentales para la seguridad y el transporte.

- Certificaciones específicas del mercado: Para proyectos de gran volumen, podemos guiarle y apoyarle en la solicitud de certificaciones de producto final como CE, FCC o KC.

Póngase en contacto con nosotros para obtener una consulta gratuita

Deje de comprometerse con baterías mal ajustadas. Nuestro equipo de ingenieros está dispuesto a colaborar con usted para diseñar una solución energética precisa, segura y de alto rendimiento.

Póngase en contacto con nosotros para obtener una consulta gratuita.

Correo electrónico: info@landazzle.com

Whatsapp: +8618938252128

Pilas con forma personalizada - Fabricante de pilas con forma de petaca