In a world untethered by wires, from the smartphone in your pocket to the drone soaring overhead, one technology has been a quiet enabler: the battery. The relentless drive for smaller, lighter, and more powerful devices has pushed battery innovation to its limits. At the forefront of this evolution is Li Polymer Battery Cell Technology. Lithium Polymer (LiPo) batteries are a key player in modern electronics, offering a unique combination of power, weight, and flexibility that traditional batteries can’t match. This article provides a deep dive into the structure, features, and benefits of LiPo technology, explaining why it has become the power source of choice for so many of today’s most innovative products.

What is a Lithium Polymer Battery

At its core, a Lithium Polymer battery is a type of rechargeable battery that belongs to the larger family of lithium-ion technologies. Its fundamental working principle—the movement of lithium ions between electrodes—is the same. However, the key distinction that sets it apart and gives it its name lies in the electrolyte.

“Polymer” in LiPo

Unlike a standard lithium-ion (Li-ion) battery, which uses a liquid electrolyte, a LiPo battery uses a solid or gel-like polymer electrolyte. This electrolyte can be imagined as a dry, solid polymer film, like a piece of plastic, or a gelled composite. This innovation is what allows for the battery’s signature thinness and flexibility, as it eliminates the need for a rigid metal case to contain a liquid.

How LiPo Batteries Work

The operation of a LiPo battery is a fascinating electrochemical dance. It consists of a positive electrode (cathode), a negative electrode (anode), and the polymer electrolyte that separates them.

- During Discharge (When you use the device): Lithium ions (Li+) move from the negative electrode (typically graphite) through the polymer electrolyte to the positive electrode (often a lithium cobalt oxide). This flow of ions creates a corresponding flow of electrons in the external circuit, which is the electricity that powers your device.

- During Charging: An external power source is applied, forcing the lithium ions to move back from the positive electrode to the negative electrode, where they are stored. This process essentially resets the battery, making it ready for another discharge cycle.

Key Differences: LiPo vs. a Standard Lithium-Ion (Li-ion) Battery

The primary difference is physical. A standard Li-ion battery is typically encased in a rigid, cylindrical metal shell (like an 18650 cell). A LiPo battery uses a flexible, foil-like pouch, making it a “pouch cell.” This structural difference is the source of many of LiPo’s unique advantages and disadvantages.

Structure of Li Polymer Battery Cell

To truly appreciate LiPo technology, we must look inside. A LiPo cell is constructed like a multi-layered sandwich, with each layer playing a critical role. These layers are stacked, wound, and sealed inside the flexible pouch.

The Positive Electrode (Cathode)

The cathode is the positive terminal of the battery. In most LiPo batteries, it’s made from a compound called Lithium Cobalt Oxide (LiCoO_2). This material is coated onto a thin aluminum foil, which acts as a current collector. The specific chemistry of the cathode material is a major determinant of the battery’s characteristics, such as its voltage and capacity.

The Negative Electrode (Anode)

The anode is the negative terminal and is where the lithium ions are stored when the battery is charged. It is typically made of carbon, usually in the form of graphite, coated onto a copper foil. The porous structure of the graphite allows it to effectively absorb and release lithium ions during the charge and discharge cycles.

The Solid Polymer or Gel Electrolyte

This is the heart of the LiPo battery and its key innovation. Instead of a liquid solvent, the electrolyte is a solid polymer composite or a highly conductive gel. Its job is to act as a medium for ion transport, allowing lithium ions to flow between the anode and cathode while blocking the passage of electrons, which are forced through the external circuit. This solid-state nature is what eliminates the need for a rigid casing.

The Separator

Sandwiched between the anode and cathode is a microporous separator. This is a very thin sheet of a polymer membrane filled with microscopic holes. It acts as an insulator, physically separating the positive and negative electrodes to prevent a short circuit, while still allowing the lithium ions to pass through unimpeded.

The Flexible Pouch Enclosure

All these components are housed in a soft, lightweight, and flexible pouch. This pouch is typically made from an aluminum-laminated film. The terminals of the battery, usually flat tabs, protrude from the pouch and are sealed to create an airtight enclosure. This pouch design is what gives LiPo batteries their incredible versatility in shape and size.

Core Features and Unmatched Benefits of LiPo Technology

The unique structure of LiPo batteries gives rise to a set of features and benefits that make them ideal for a wide range of modern applications.

Densité énergétique élevée

Energy density refers to the amount of energy a battery can store for its size or weight. LiPo batteries boast a very high energy density, meaning they can pack more power into a smaller and lighter package compared to other rechargeable batteries like Nickel-Cadmium (NiCd) or Nickel-Metal Hydride (NiMH). This is the single most important reason they are used in portable devices where weight and size are critical, such as drones and smartphones.

Unparalleled Flexibility

Because LiPo batteries don’t require a rigid metal case, they can be manufactured in an almost endless variety of shapes and sizes. They can be made ultra-thin (sometimes less than 1mm), curved, or molded to fit into the tight, unconventional spaces within a product’s design. This design freedom is a massive advantage for engineers creating the sleek, compact devices we use every day. For a deeper dive, Epec offers a detailed comparison between LiPo and Li-ion cells.

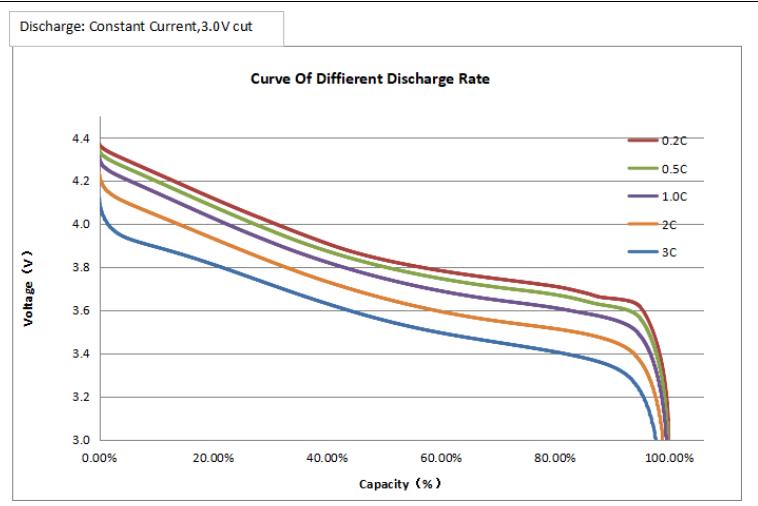

Taux de décharge élevé

Many modern electronics require large bursts of power. A LiPo battery’s ability to deliver this is measured by its Note C. A higher C-rating means the battery can discharge its energy more quickly without being damaged. This high discharge capability is essential for performance-driven applications like FPV racing drones, which need instant power for rapid acceleration and acrobatic maneuvers, or for power tools that require high torque.

Low Self-Discharge and No Memory Effect

LiPo batteries hold their charge well when not in use, exhibiting a very low self-discharge rate. Furthermore, they do not suffer from the “memory effect” that plagued older battery chemistries. The memory effect is a phenomenon where a battery loses its maximum energy capacity if it is repeatedly recharged after being only partially discharged. LiPo batteries can be topped off from any charge level without this concern.

Enhanced Safety Characteristics

While no battery is completely without risk, the polymer electrolyte in LiPo cells is considered safer than the liquid electrolyte in traditional Li-ion cells because it is less prone to leakage. In the event of a failure, such as overcharging or a puncture, a LiPo battery is more likely to swell or “puff up” rather than undergo a violent explosion with flying shrapnel, which can happen with rigid metal-cased cells.

Real-World Applications: Where LiPo Batteries Shine

The unique benefits of LiPo technology have made it the go-to power source for a vast array of cutting-edge products.

Drones and RC Vehicles

The world of unmanned aerial vehicles (UAVs), or drones, has been revolutionized by LiPo batteries. The critical need for a high power-to-weight ratio makes LiPo the perfect choice. They provide the high current necessary for powerful motors while keeping the overall weight of the aircraft low, resulting in longer and more agile flights. The same principle applies to high-performance remote-controlled cars, planes, and boats.

Électronique grand public

Look no further than your smartphone, tablet, or smartwatch. The slim and sleek designs of these devices are made possible by the thin, custom-shaped LiPo batteries inside them. Manufacturers can design a battery that perfectly fills the internal cavity of a device, maximizing capacity without wasting space or adding unnecessary bulk.

Medical and Industrial Fields

In the medical field, portable devices like ECG monitors, infusion pumps, and portable oxygen concentrators rely on LiPo batteries for their reliability and compact size. In industrial settings, they power portable scanners, sensors, and other specialized tools where dependable, lightweight power is essential for on-the-go professionals.

Safety, Handling, and Lifespan: Best Practices for LiPo Users

With great power comes great responsibility. The high energy density of LiPo batteries means they must be handled with care to ensure safety and longevity.

Understanding the Risks: Swelling, Punctures, and Overcharging

The most common failure mode for a LiPo is swelling. This happens when the battery is overcharged, over-discharged, punctured, or overheats, causing the electrolyte to break down and release gas. This gas is what makes the pouch “puff up.” A swollen battery is permanently damaged and should be safely disposed of, not used. A physical puncture is extremely dangerous and can lead to an immediate fire. To ensure safety, batteries should always meet standards from certification bodies like UL Solutions.

Proper Charging, Discharging, and Storage

- Chargement : Always use a charger specifically designed for LiPo batteries, preferably a balance charger that monitors and charges each cell individually. Never leave a charging battery unattended.

- Décharge : Avoid over-discharging your battery. Most electronic devices have a built-in cutoff, but for hobbyist applications, it’s crucial to monitor the voltage and not let it drop below 3.0V per cell.

- Stockage : For long-term storage, LiPo batteries should be kept at a partial charge, around 40-60% of their capacity (or roughly 3.8V per cell). Store them in a cool, dry place inside a fireproof LiPo bag.

Maximizing Cycle Life: How Long Do LiPo Batteries Last?

A well-maintained LiPo battery can typically last for 500 to 1000 charge cycles. A charge cycle is a full discharge followed by a full charge. How you use, charge, and store the battery will have the biggest impact on its lifespan. Adhering to the best practices above will ensure you get the most life out of your battery.

Conclusion

Lithium Polymer battery cell technology represents a significant leap forward in energy storage. Its unique combination of high energy density, a lightweight and flexible form factor, and a high discharge rate has reshaped the landscape of modern electronics. From enabling the sleek designs of our favorite gadgets to providing the raw power needed for high-performance hobbies, LiPo batteries are an indispensable component of our increasingly mobile and power-hungry world. As research continues to push the boundaries of polymer science, the future promises even safer, more powerful, and longer-lasting batteries that will power the innovations of tomorrow.

Au Lan DazzleNous sommes spécialisés dans la conception et la fabrication batteries Li-Polymère sur mesure to match the exact specifications of your product—no matter how compact, curved, or unconventional the form factor may be. Whether you’re building next-gen wearables, medical devices, drones, or smart consumer electronics, our team ensures optimal battery performance, safety, and seamless integration. From concept to mass production, we provide reliable engineering support and fully customized battery solutions to power your innovation.

📩 Contactez-nous dès aujourd'hui à info@landazzle.com to discover how we can bring your product to life with a battery built just for it.