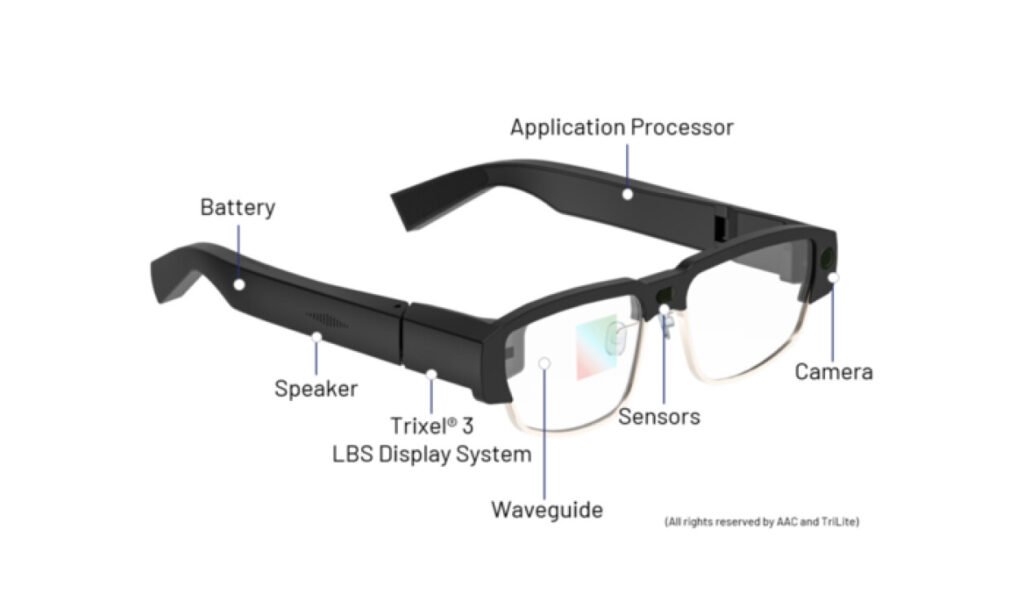

Smart glasses are moving from futuristic concepts to everyday wearable technology. With the rise of AR, AI, and lightweight computing, the global smart glasses market is growing rapidly—expected to reach over USD 8 billion by 2030.

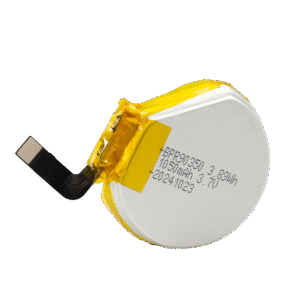

As designs become slimmer and smarter, one component determines how long and how comfortably these devices can run—the battery. A well-designed power solution not only extends usage time but also defines the comfort, safety, and reliability of the product.

So, how do you choose the right battery for smart glasses that balances lightweight design, long runtime, and safety?

Let’s explore what makes the ideal power source for smart glasses.

Key Requirements for Smart Glasses Batteries

Lightweight & Compact: Batteries must be ultra-light and low-profile (ideally a few grams each). Even 50 g can feel heavy for all-day wear.

High Energy Density & Long Runtime: Lithium-polymer (LiPo) cells store enough energy to power displays, processors, and sensors for hours without adding bulk.

Custom Shapes & Thinness: Batteries can be L-shaped, curved, or ultra-thin (as slim as 0.5 mm) to fit into temples or bridges, maximizing space in slim frames.

High Discharge Rate & Stable Performance: Support bursts of power (3–10 C) for sensors and Bluetooth, with quick charge/discharge (3–5 C) and minimal voltage sag.

Safety & Thermal Management: Must include protection circuits and thermal layers; rated for wide temperature ranges (–50°C to +60°C) to prevent overheating.

Certifications & Compliance: Should meet UL 2054/UL 1642, IEC 62133, UN 38.3, CE, RoHS, etc., to ensure consumer safety and simplify regulatory approval.

Which Battery Type Last Longer for AR Glasses?

When it comes to AR glasses, battery life is critical due to the need for lightweight, compact, and long-lasting power sources. Here’s a comparison of common battery types:

- Lithium-Polymer (LiPo) Batteries

- Best for AR Glasses: LiPo cells offer high energy density in a thin, lightweight form factor, making them ideal for temples or bridge placement.

- Long Runtime: Can store enough energy to power displays, sensors, and processors for several hours.

- Custom Shapes: Available in curved, L-shaped, and ultra-thin configurations to maximize space usage.

- Stable Performance: Supports moderate to high discharge rates (3–10 C) without significant voltage sag.

- Safety & Reliability: Can include protection circuits and thermal management layers for safe operation.

- Lithium-Ion (Li-ion) Cylindrical or Prismatic Batteries

- Higher Capacity: Can store slightly more energy in standard sizes, but bulkier and heavier.

- Less Flexible Form Factor: Hard to integrate into slim glasses frames without compromising comfort.

- Moderate Discharge: Typically lower discharge rates than LiPo, which may limit peak performance for sensors or wireless communication.

Conclusion:

For AR glasses, LiPo batteries are generally the best choice due to their combination of high energy density, lightweight design, custom shapes, and reliable performance. They provide longer usable runtime in a form factor that fits seamlessly into wearable designs.

Can I Use Off-the-Shelf Lipo Batteries?

While off-the-shelf LiPo batteries are widely available, they are not always ideal for AR glasses. Here’s why:

- Size & Shape Limitations: Standard LiPo cells usually come in rectangular or square formats that may not fit slim or curved frames, limiting design flexibility.

- Weight Concerns: Pre-made cells may be heavier than custom ultra-thin options, which can make glasses uncomfortable for all-day wear.

- Performance Constraints: Off-the-shelf batteries may not support high discharge rates required for sensors, displays, and wireless communication in AR devices.

- Safety & Compliance: Consumer-grade cells may lack integrated protection circuits or thermal management, and may not have certifications (UL, IEC, UN38.3) needed for wearables.

When Off-the-Shelf Batteries Might Work:

- Prototypes or early-stage testing where form factor is not critical.

- Devices with lower power requirements and less emphasis on runtime.

Recommendation:

For commercial AR glasses, it’s best to use custom-shaped LiPo batteries. They provide:

- Ultra-thin, curved, or L-shaped designs for optimal fit.

- Lightweight construction for comfort.

- High discharge rates for stable performance.

- Built-in safety features and global certifications for compliance.

How to Choose Battery for Smart Glasses

Capacity & Voltage Needs: Calculate the glasses’ power draw (display, chipset, radio) to determine required mAh. More capacity extends life but adds size. For example, a pair of smart glasses drawing ~100 mA average might need a 500 mAh pack for ~5 hours. Voltage must match the device; common single-cell LiPo is 3.7–4.2V, or multiple cells in series for higher voltage.

Discharge Rate (C-rating): Ensure the cell supports the peak current of your device (e.g., high C-rate for real-time video or wireless bursts).

Cycle Life & Durability: Pick cells rated for ≥1000 cycles if the device will be charged daily. Our batteries are rated for >80% capacity after 1000+ cycles, ensuring years of use. Higher-grade LiPo chemistries and quality control drive this longevity.

Physical Layout & Integration: The battery must match the glasses’ mechanical design. For instance, batteries placed in the temples may need an “L” shape to route around hinges. Utilizing a custom battery manufacturer means these unique shapes can be fabricated to spec, unlike off-the-shelf cells.

Charging Method: Decide if the glasses use wired or wireless charging. LiPo chemistry supports fast wired charging (up to 5C). For wireless, ensure the cell and protection circuitry handle lower voltage/current profiles. We can integrate custom PCM/BMS boards to manage both modes safely.

Thermal Management: AR glasses often use processors for graphics; the battery should tolerate the heat or include thermal isolators. Cells with good thermal performance and heat-dissipating packaging are recommended.

Safety Systems: Include a BMS or protection IC to prevent over-charge/discharge. We can integrate micro-PCBs for voltage/temperature sensing. Our custom cells support either embedded PCMs or external BMS integration to meet your safety design.

LanDazzle Custom Lipo Battery Solutions

Irregular Batteries: We specialize in custom-shaped LiPo batteries, ideal for eyewear temples or bridge sections. Our shaped cells can be tailored in thickness/length for your frame.

Ultra-Thin Cells: Our technology yields pouch batteries thinner than 1 mm. For example, we produce LiPo cells as thin as 0.6 mm – perfect for book-style temples or behind displays.

Integrated Pack Options: We offer single-cell designs or multi-cell packs with internal wiring and connectors. For convenience, we can deliver a ready-to-install pack with solder tabs, cables or even SMT contacts. Internal PCM (protection circuit) can be included to safeguard each cell.

Rapid Prototyping: Using our online Battery Workshop tool or engineering support, you can rapidly iterate on battery designs. Send us size sketches or 3D models, and our team will recommend the optimal LiPo configuration and capacity. This collaborative design process ensures the battery fits the product design as if it were custom-designed for it – because it is.

Technology Innovation and Performance

- Advanced Cell Chemistry: High-purity electrodes and proprietary formulations maximize energy density.

- Stacked (Laminated) Construction: Enables custom shapes (L-shaped, curved, ultra-thin) and thicknesses that traditional wound cells cannot achieve.

- High-Rate & Fast-Charge: Supports 3–5 C charge/discharge for quick recharging (~15–20 min for 3 C).

- Enhanced Safety: Multi-layer separators, thermal additives, UL/IEC tested, with integrated PCM boards for cell balancing and cutoff protection.

Manufacturing Capacity and Quality Assurance

- High-Volume Production: Automated lines produce millions of cells annually, including pouch and custom-shaped cells, ensuring consistent quality for large OEM orders.

- Quality Control: Rigorous testing (capacity, cycle, leak, safety) with nearly 100% yield on mature models; batches are tracked and serialized.

- Certifications: ISO 9001, ISO 13485, OHSAS, UL recognition, ensuring processes meet international standards and product reliability.

- Global Supply Chain: In-house production minimizes supply risks, supports on-time delivery, and ensures consistent pricing worldwide.

- Environmental Compliance: Cells meet RoHS, REACH, and other regulations, making products market-ready globally.

Safety Standards and Certifications

- UL / IEC / UN38.3: Designed and tested to meet UL 1642 & UL 2054, IEC 62133, and UN 38.3 standards; certification documents available for submissions.

- RoHS & REACH: Uses compliant materials and low-toxicity chemicals, ensuring global market access.

- Additional Regulatory Support: Assistance with regional certifications (e.g., China CCC, Korea KC, Japan PSE) and pre-certified cells for faster wearable electronics approvals.

How to Partner with Us

Consultation & Design: First, we review your product requirements: power, size constraints, certifications needed, and volume. Our engineers then propose custom battery designs optimized for your smart glasses (e.g. an 1800 mAh L-shape for a head-mounted display).

Rapid Prototyping: We can quickly produce prototype cells for functional testing, including characterizing performance and verifying fit in your device. This allows you to validate battery life and thermal behavior before mass production.

Scalable Production: Once the design is locked, we ramp up to meet your volumes – from small runs to millions of units. Our automated facilities and supply chain management ensure we can scale without quality loss.

Ongoing Support: We provide detailed datasheets, safety documentation and continuous quality tracking. If your design evolves, we can iterate battery specs and tooling. Technical support is available throughout the partnership.

Why Choose Our Custom Batteries: By selecting our LiPo batteries, you leverage our strengths in innovation, customization, and certified manufacturing. We allow smart glasses makers to focus on their core features, knowing the power system is expertly handled.

Conclusion

Choosing the right battery for smart glasses is about more than just power — it’s about achieving the perfect balance between size, performance, and safety. As smart eyewear continues to evolve, only a custom lithium polymer battery can truly meet the unique demands of compact space and all-day operation.

We specialize in designing and manufacturing custom LiPo batteries that empower next-generation wearable devices.

If you’re developing smart glasses and need a reliable power partner, LanDazzle is here to help you bring innovation to life.

Email: info@landazzle.com

Whatsapp: +8618938252128