Introduction: The Power of Form

In today’s fiercely competitive product landscape, miniaturization, seamless aesthetics, and groundbreaking functionality are paramount. Yet, for many product designers, a fundamental challenge persists: power. Traditional, off-the-shelf cylindrical or prismatic batteries, while reliable, often become the primary constraint, dictating the form factor of a device rather than enabling it. This is where custom shaped batteries emerge as a revolutionary solution, liberating design engineers from conventional limitations and unlocking unprecedented innovation.

No longer a niche component, custom shaped batteries are becoming indispensable, particularly in industries where space is at an absolute premium – from the intimate contours of wearables and the life-critical precision of medical devices to the ubiquitous integration of IoT sensors and the sleek appeal of consumer electronics. This article delves into the profound impact of custom shaped batteries, exploring their benefits, key design considerations, and their role in powering the next generation of truly bespoke products.

The Evolving Landscape of Device Design: Why Standard Batteries Fall Short

The relentless march of technology demands ever-smaller, more powerful, and aesthetically pleasing devices. Consumers expect smartwatches to blend seamlessly with their attire, medical implants to be imperceptible, and IoT sensors to vanish into their environments. This drive towards miniaturization and unique aesthetics has reshaped the core philosophy of product design.

However, standard battery formats often stand as a rigid impediment. Imagine trying to fit a rectangular peg into a circular hole; traditional batteries frequently leave significant voids within a device’s enclosure, wasting precious internal volume. This compromise not only leads to larger, bulkier products but also restricts creative freedom, forcing designers to build their innovations around the battery rather than integrating the battery into the innovation.

The limitations extend beyond mere geometry. With standard batteries, designers face constraints on achieving optimal weight distribution, ergonomic comfort (especially crucial for wearables), and the sleek, integrated look that defines modern electronics. As the global wearable tech market continues its robust expansion, projected to reach billions in the coming years, and IoT device proliferation accelerates exponentially, the demand for optimized power solutions that transcend these limitations has never been more critical. Custom shaped batteries are no longer a luxury; they are a strategic necessity for maintaining a competitive edge and bringing truly groundbreaking products to market.

What Are Custom Shaped Batteries?

At its core, a custom shaped battery is a power cell meticulously designed and manufactured to fit specific, non-standard dimensions or unique geometries, often defying the conventional rectangular or cylindrical forms. Unlike the mass-produced, off-the-shelf batteries that define their own space requirements, custom shaped batteries are precisely tailored to utilize every available millimeter within a product’s enclosure.

The primary chemistries leveraged for these bespoke power solutions are Ioni di litio (Li-ion) and, more commonly for complex shapes, Polimero di litio (Li-Po). Lithium Polymer batteries, in particular, offer superior flexibility in packaging, allowing for ultra-thin profiles, curved designs, and even intricate cut-outs to accommodate other internal components. This flexibility stems from their use of a polymer electrolyte rather than a liquid one, which enables the use of soft-pack (pouch cell) casing that can be molded or cut into virtually any desired form.

The manufacturing process for custom shaped batteries typically involves taking standard battery materials (anodes, cathodes, separators, electrolytes) and customizing the cell stacking or winding process, followed by precision cutting and sealing into the desired unique form factor. This enables the creation of incredibly diverse designs, from credit card-thin cells for smart wallets to curved batteries that seamlessly wrap around a smart ring, or even L-shaped and circular batteries for compact consumer electronics where space is irregular. The customization extends beyond just the outline; it includes precise control over thickness, curvature, and the strategic placement of terminals, ensuring perfect integration into the device’s interior architecture.

The Untapped Potential: Benefits of Custom Shaped Batteries for Product Designers

For product designers, custom shaped batteries represent a paradigm shift, transforming constraints into opportunities for innovation. Their benefits extend far beyond mere fit, profoundly impacting a product’s form, function, and market appeal.

-

Maximizing Space Utilization (Addressing Space Constraints Directly): This is arguably the most significant advantage. By precisely conforming to the irregular voids and contours within a device, custom batteries eliminate wasted space that conventional batteries would leave untouched. This reclaimed volume can be leveraged in multiple ways:

- Smaller Device Footprint: The device itself can be significantly smaller and lighter, a critical factor for wearables like smartwatches and fitness trackers where comfort and discretion are paramount.

- Increased Battery Capacity: By filling more of the available volume, designers can pack more active material into the same product dimensions, directly translating to higher battery capacity and longer battery life. For example, a medical sensor designed with a custom-shaped battery might gain an additional 20-30% capacity compared to one forced to accommodate an off-the-shelf cell, extending operational time and reducing the need for frequent recharges or replacements.

- Accommodation of Additional Features: The freed-up space can also be used to integrate more sensors, advanced processing units, or other components, enhancing the product’s functionality without increasing its overall size.

-

Enhanced Product Aesthetics & Ergonomics: Custom batteries empower designers to craft organic, flowing, and truly integrated designs.

- Seamless Integration: No more unsightly bulges or awkward protrusions. A curved battery for a smart ring ensures a comfortable, natural fit around the finger, improving user experience and wearability.

- Sleeker Profiles: Achieve ultra-thin form factors for devices like smart credit cards or medical patches that need to be unobtrusive.

- Brand Differentiation: Unique product shapes enabled by custom batteries can create a distinctive brand identity in crowded markets.

-

Design Freedom & Innovation: The ability to literally shape the power source breaks traditional design barriers. This flexibility fosters radical innovation, enabling products that were previously impossible due to battery limitations. Imagine wearable patches that conform to the body, miniature diagnostic tools for ingestible applications, or IoT sensors designed to fit into unusually shaped industrial equipment – all made possible by tailored power solutions. This freedom accelerates the design process, allowing engineers to focus on user experience and advanced features rather than struggling with battery placement.

-

Competitive Advantage: In industries defined by rapid technological advancement and fierce competition, custom shaped batteries provide a distinct edge. Products that are smaller, lighter, last longer, and possess superior aesthetics inherently stand out. This competitive advantage is crucial for securing market share and establishing leadership in the wearables, medical device, and IoT sectors. Consider how a company offering a truly discreet and long-lasting medical implant, made possible by a perfectly fitted custom battery, gains a significant lead over competitors using bulkier standard solutions.

Key Design Considerations for Custom Shaped Batteries

While the benefits are compelling, designing with custom shaped batteries requires a meticulous approach and close collaboration with battery manufacturers. Product designers must consider several critical factors to ensure optimal performance, safety, and manufacturability.

-

Early-Stage Collaboration with Manufacturers: This is perhaps the most crucial step. Engaging battery specialists during the conceptual design phase allows for iterative discussions on feasibility, material limitations, potential performance trade-offs, and cost implications. An experienced manufacturer can provide invaluable insights into what shapes are achievable, the thinnest possible profiles, and how to optimize energy density for a given volume. This proactive approach prevents costly redesigns down the line.

-

Battery Chemistry Selection: While Li-ion and Li-Po are dominant, the choice between them or specific variations depends on the application. Li-Po offers greater flexibility for complex shapes and ultra-thin profiles due to its soft-pack construction, but Li-ion might offer slightly higher energy density for certain prismatic custom designs. Factors like desired cycle life, operating temperature range, and safety requirements will influence the best chemistry.

-

Voltage, Capacity & Discharge Rate: These fundamental electrical parameters must precisely match the device’s power requirements. Product designers need to provide accurate power consumption profiles (peak current, average current, sleep current) and desired operating voltage to the battery manufacturer. The battery’s capacity (mAh or Wh) will then be tailored to meet the target runtime, while the discharge rate must comfortably handle the device’s peak power demands without significant voltage drop.

-

Gestione termica: Even custom-shaped batteries generate heat during charging and discharging cycles. In tightly packed enclosures, proper thermal management is paramount to prevent overheating, which can degrade battery performance, shorten lifespan, and pose safety risks. Designers must consider heat dissipation pathways, material choices for enclosures, and potentially integrate passive or active cooling solutions. The better fit of a custom battery can sometimes aid in heat transfer to the device casing, but robust thermal design is always essential.

-

Safety & Certification: Adherence to international safety standards is non-negotiable. Batteries, especially Li-ion and Li-Po, carry inherent risks if not designed, manufactured, and integrated correctly. Key standards include UN38.3 (for transportation), IEC 62133 (for rechargeable cells and batteries), and UL certification for specific product categories. Manufacturers of custom batteries must demonstrate rigorous testing and compliance. Product designers are responsible for ensuring the overall device’s safety, including proper Battery Management System (BMS) integration, overcharge/discharge protection, and short-circuit prevention.

-

Prototipazione e test: The design process for custom batteries is iterative. Initial prototypes are essential for verifying the fit, form, and preliminary electrical performance. Extensive testing – including cycle life, temperature performance, vibration, drop, and short-circuit tests – is crucial to validate the battery’s reliability and safety in the actual device environment before mass production.

-

Manufacturing Scalability & Cost: While custom solutions offer unparalleled design freedom, designers must also consider the manufacturing process and associated costs. Initial tooling costs for custom molds can be higher than for standard batteries, making them most viable for higher-volume production runs or products with high unit value. Discussing MOQs (Minimum Order Quantities) and per-unit costs early with the manufacturer is vital.

-

Durability & Environmental Factors: Depending on the product’s intended use, the custom battery may need to withstand specific environmental conditions, such as extreme temperatures, humidity, shock, or vibration. The battery’s encapsulation and internal construction must be robust enough to ensure reliable operation throughout its lifespan in these conditions. An appropriate IP rating (Ingress Protection) might also be necessary for devices exposed to dust or water.

The Future of Power: Innovations in Custom Battery Technology

The evolution of custom shaped batteries is far from over. As devices become even more integrated, flexible, and powerful, battery technology is responding with groundbreaking innovations. We are on the cusp of seeing:

- Batterie a stato solido: These next-generation batteries promise higher energy density, faster charging, and significantly improved safety compared to current Li-ion/Li-Po technologies. Their solid electrolyte could enable even more radical form factors, making truly flexible or even structural batteries a reality.

- Even Thinner Profiles: Research continues into producing batteries measured in microns rather than millimeters, opening doors for ultra-thin smart cards, active medical patches, and disposable diagnostic tools.

- Flexible Printed Batteries: Advances in materials and printing techniques could allow batteries to be printed directly onto flexible substrates, further enhancing their conformability and integration possibilities.

- Micro-Batteries: For highly miniaturized applications, micro-batteries with capacities in the micro-ampere-hour range are being developed, specifically designed for minute IoT sensors or ingestible electronics.

These advancements will continue to fuel the demand for highly specialized power solutions, further cementing the role of custom shaped batteries as a cornerstone of future product innovation across all industries.

Conclusion: Powering the Next Generation of Innovation

In the relentless pursuit of smaller, smarter, and more aesthetically pleasing devices, the battery has traditionally been a limiting factor. However, the advent and maturation of custom shaped batteries have fundamentally reshaped the landscape of product design. By precisely tailoring power solutions to the unique contours and space constraints of wearables, medical devices, IoT sensors, and consumer electronics, designers are now empowered to create products that were once confined to the realm of imagination.

These bespoke power sources are not just components; they are enablers of miniaturization, catalysts for aesthetic excellence, and drivers of unparalleled functionality. For product designers navigating the complexities of modern hardware development, embracing custom battery solutions is no longer an option but a strategic imperative to unlock true innovation and deliver the next generation of groundbreaking products that seamlessly integrate into our lives.

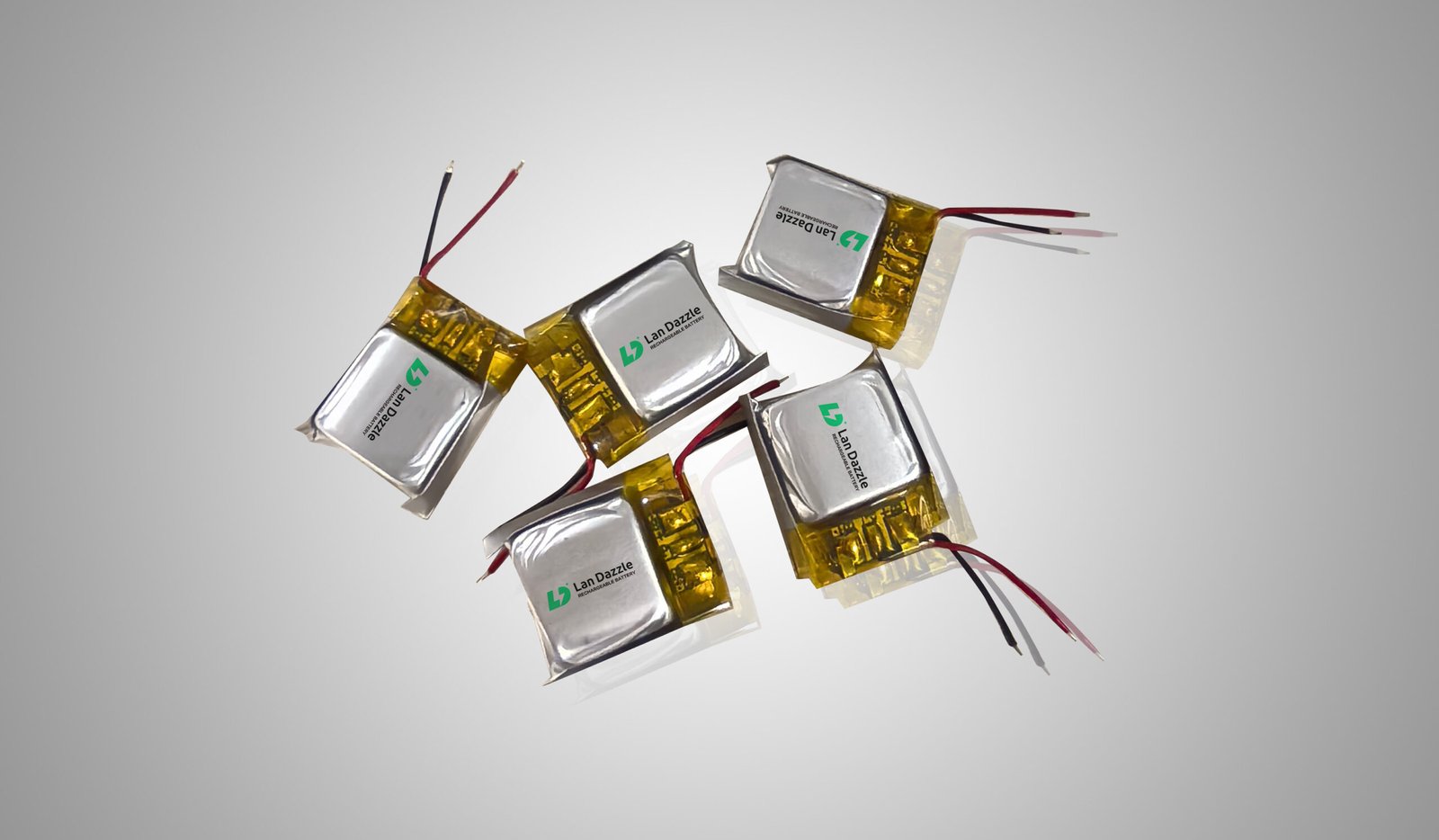

Partner with Lan Dazzle for Your Custom Shaped Battery Needs

A Lan Dazzle, we specialize in designing and manufacturing high-quality custom shaped batteries to meet the most demanding application requirements. Whether you need batteries for wearables, medical devices, IoT products, smart rings, helmets, robotics, or other compact and uniquely shaped products — we deliver power solutions perfectly tailored to your design.

Our advantages include:

-

Fully customized designs to fit your product’s exact shape and dimensions

-

Alta densità di energia e lightweight construction

-

Flexible production for small to large batch quantities

-

Controllo di qualità rigoroso e certifications for global markets

-

Fast prototyping e responsive engineering support

If you’re looking for a trusted custom battery partner to help bring your next innovation to life, Lan Dazzle is here to help.

👉 Contattateci oggi stesso al info@landazzle.com to discuss your project and explore how our custom shaped battery solutions can empower your product design.