Ever wondered why the battery in your slim smartphone is flat, while the one in your chunky power drill is made of round cells? It’s not a random design choice. The shape of a lithium-ion battery—the powerhouse behind most of our modern gadgets—has a huge impact on everything from its performance and safety to its cost.

The two main players in this world are the Li Polymer battery cell, which you can think of as a “flat” or “pouch” battery, and the Cylindrical cell, which looks like a classic round battery. Understanding the difference between them is key to appreciating the technology you use every day. This guide will break down the key differences in simple terms, exploring the pros and cons of each to help you understand the tech that powers your life.

What is a Li Polymer Battery Cell

If you’ve ever seen the inside of a modern smartphone, tablet, or ultra-thin laptop, you’ve met a Li-Polymer battery. These flat, flexible power packs are the champions of compact design.

How It’s Made

Think of a Li-Polymer battery as a high-tech sandwich. It’s made of super-thin layers of positive and negative material with a separator sheet in between. The “jelly” in this sandwich is a chemical paste or gel-like substance called a polymer electrolyte. This entire layered stack is then sealed inside a soft, flexible, foil-like bag or “pouch.” There is no hard metal can, which is what makes the battery so light and adaptable.

Main Features

The genius of the LiPo battery lies in its construction. Its defining features are:

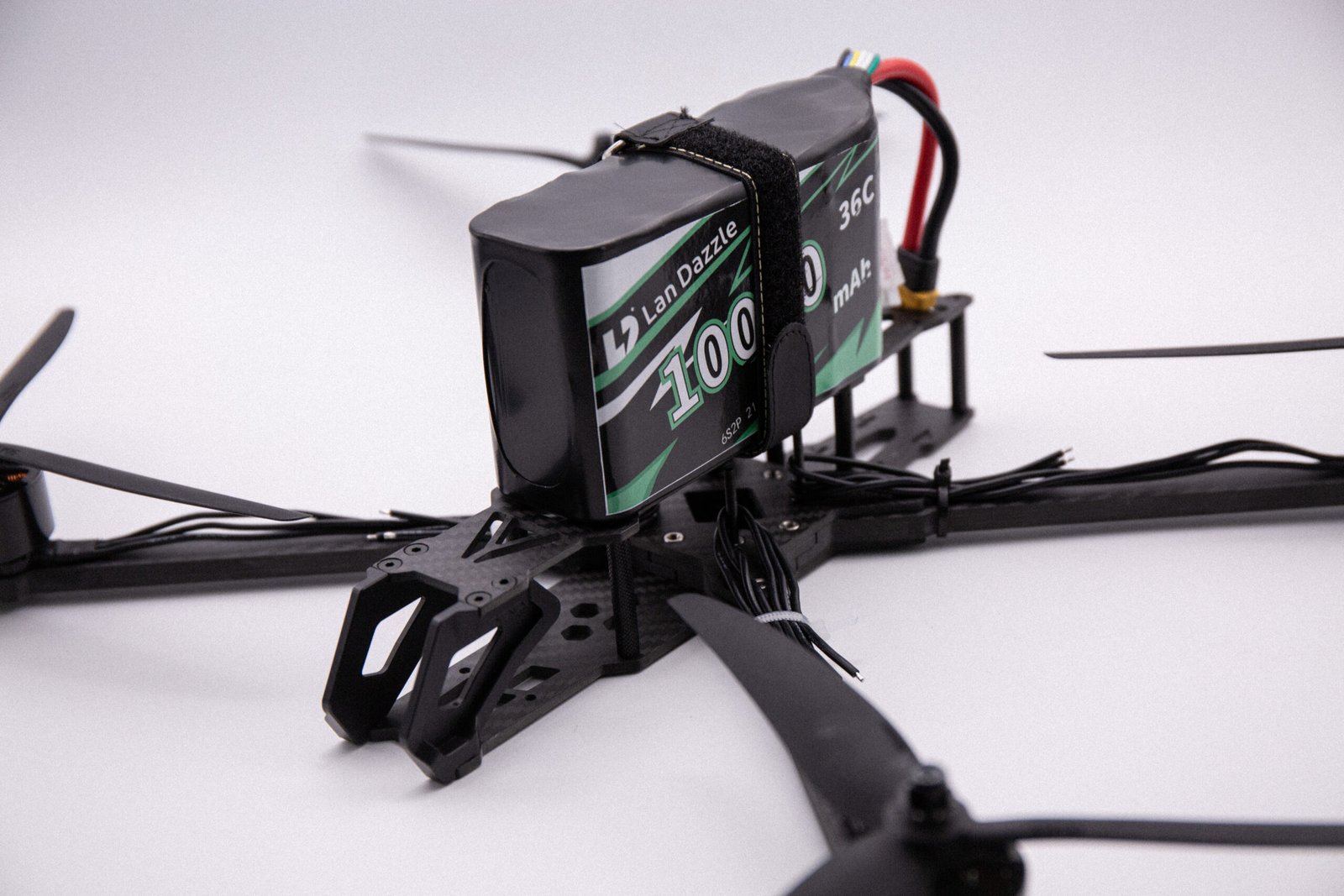

- Leggero: With no heavy metal casing, LiPo batteries are significantly lighter than their cylindrical cousins. This is a huge advantage for devices you carry around or that need to fly, like drones.

- Ultra-Thin & Flexible: LiPo cells can be made incredibly thin—sometimes less than a millimeter—and can be produced in a wide variety of custom shapes and sizes. This allows product designers to get creative and build the sleek, curved, and compact gadgets we love. They are the “designer” battery, tailored to fit perfectly into a specific product.

What is a Cylindrical Cell

The cylindrical cell is the traditional workhorse of the lithium-ion world. It’s a design that has been perfected over decades and is known for its strength, reliability, and cost-effectiveness. The most famous size is the “18650,” but they come in many sizes.

How It’s Made

The manufacturing process for a cylindrical cell is completely different. Instead of stacking layers, manufacturers take long strips of the positive and negative materials and the separator and roll them up tightly, like a Swiss roll or a jelly roll. This roll is then inserted into a strong, rigid metal can, usually made of steel or aluminum. The can is then filled with a liquid chemical core (the electrolyte) and sealed shut.

Main Features

The “heavy-duty” nature of the cylindrical cell gives it a distinct set of advantages:

- Robust and Durable: The hard metal case provides excellent protection from bumps, vibrations, and pressure. This makes them ideal for rugged applications where they might get knocked around.

- Standardized and Cost-Effective: Because cylindrical cells are made in standard sizes (like the 18650), the manufacturing process is highly automated and incredibly efficient. This mass production makes them cheaper to produce than the more custom LiPo cells.

- Excellent Thermal Management: The round shape and the gaps between cells when they’re bundled into a pack allow for good airflow, making them easier to cool, which is critical in high-power applications like electric cars.

Li-Polymer vs. Cylindrical

So, how do these two battery types stack up against each other in a direct comparison? It all comes down to a series of trade-offs.

| Caratteristica | Li-Polymer (Pouch) Battery | Batteria cilindrica |

|---|---|---|

| Shape & Design | Flexible, slim, and customizable. | Rigid, strong, and standardized. |

| Peso | Lighter. | Heavier. |

| Durata | More fragile, can be punctured. | Very durable and physically resistant. |

| Safety Risk | Tends to swell as a warning sign. | Can “vent” gas forcefully if it fails. |

| Costo | More expensive. | Cheaper due to mass production. |

| Il migliore per | Thin and light devices (phones, drones). | High-power, rugged uses (power tools, EVs). |

Design & Shape: Freedom vs. Strength

The biggest win for LiPo batteries is their design freedom. They allow for the creation of incredibly thin gadgets. A cylindrical cell simply couldn’t fit into an Apple Watch or the latest razor-thin laptop.

The downside of the LiPo’s soft pouch is its fragility. On the other hand, the cylindrical cell’s strength is also its weakness in design—it’s bulky, and when you bundle them together, you’re left with unused empty space between the round cans.

Weight & Power Capacity: The Trade-Off

When we talk about power capacity, we often mean “energy density”—simply put, how much juice can be packed into a battery for its size or weight. LiPo batteries generally have a higher energy density for their weight because they don’t have that heavy metal can. This is critical for a drone, where every gram saved means more time in the air. Cylindrical cells are a bit heavier for the same power, but advancements are closing this gap.

Performance: How They Deliver Power

Both battery types can be designed for high performance. The speed at which a battery can release its energy is often called its “discharge rate” or “C-rate.” A power tool needs a very high discharge rate for a quick burst of intense power to spin a drill bit. A laptop needs a slower, steadier discharge to last for hours.

Both pouch and cylindrical cells can be made for high or low power delivery. Lifespan, or the number of times a battery can be recharged (its “cycle life”), also has more to do with the battery’s internal chemistry and how you treat it than its shape. Avoiding extreme temperatures and not draining your battery to zero are far more important for a long life.

Safety: Swelling vs. Venting

Safety is paramount, and both designs have safety features built in. The most common failure for a LiPo battery is swelling. Gas builds up inside the pouch, causing it to puff up like a pillow. This is a clear visual warning that the battery is damaged and needs to be replaced safely. However, if a LiPo battery is punctured, it can catch fire very quickly.

Cylindrical cells are much harder to damage physically. If they do fail due to an internal short or overheating, pressure can build inside the metal can. To prevent an explosion, they are designed to “vent” this pressure from a built-in weak point. While this is a critical safety feature, it can be quite dramatic, involving the release of hot gas and sparks. All certified lithium-ion batteries, regardless of shape, must be tested for safety standards to minimize these risks.

The Price Tag: Custom vs. Mass-Produced

This one is simple: cylindrical cells are almost always cheaper. The machinery to make them has been running for decades, producing billions of units in standardized sizes. LiPo manufacturing is a more delicate, custom process, making the end product more expensive. For companies making millions of devices, that cost difference adds up.

Real-World Uses: Where You’ll Find Them

The right battery for the job depends entirely on the product’s priorities.

Where Li-Polymer (Pouch) Batteries Shine

You’ll find LiPo batteries in devices where being thin and light is the top priority.

- Smartphones & Tablets: Their slim shape is essential for modern phone designs.

- Ultra-thin Laptops: Custom-shaped batteries fill every nook and cranny to maximize battery life.

- Drones & RC Toys: The excellent power-to-weight ratio is a must-have for flight.

- Medical Wearables & Hearing Aids: Tiny, custom batteries power small and discreet devices.

Where Cylindrical Batteries are King

Cylindrical cells are the top choice for applications that need to be durable, high-powered, and cost-effective.

- Utensili elettrici: They provide massive bursts of energy and can survive being dropped on a construction site.

- Veicoli elettrici: Many EV manufacturers build their giant battery packs from thousands of individual cylindrical cells, creating a robust and cost-effective system.

- High-Powered Flashlights: Enthusiasts prefer them for their power and durability.

- Power Banks: Their low cost allows manufacturers to offer a lot of backup power for a reasonable price.

Conclusion: The Right Tool for the Right Job

In the battle of Li-Polymer vs. Cylindrical cells, there is no single winner. The “best” battery is the one that perfectly fits the needs of the device it’s in. It’s a constant balancing act between size, weight, power, safety, and cost.

If you need a battery for a slim, lightweight gadget where every millimeter of space counts, the flexible Li-Polymer pouch is the champion. But if you need a tough, reliable, and affordable power source for a demanding application, the time-tested cylindrical cell is often the smarter choice.

The good news is that both technologies are rapidly improving. As engineers figure out new ways to make batteries that hold more juice, last longer, and are even safer, all of our devices will benefit. The next time you pick up your phone or a power drill, you’ll know exactly why its battery is shaped the way it is. And you’ll have a better understanding of the incredible science of how batteries create power inside these tiny packages.