Table of Contents

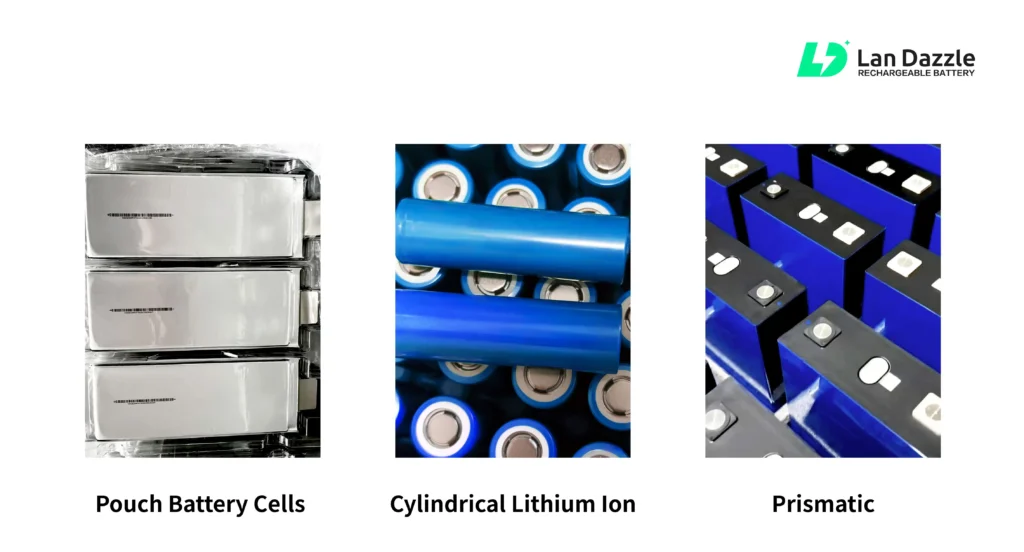

In the world of lithium-ion technology, not all battery cells are created equal. Whether you’re designing a drone, wearable device, or robotic system, the choice between pouch, cylindrical, and prismatic cells can significantly impact your product’s performance, size, and overall reliability. Each type comes with distinct structural characteristics — from the robust metal casing of cylindrical cells to the space-saving flexibility of pouch batteries.

Understanding these differences is essential for making the right decision, especially as modern devices demand higher energy density, lighter weight, and more design freedom. In this article, we’ll compare pouch battery cells vs. cylindrical lithium-ion vs. prismatic, explore their advantages and limitations, and explain why custom pouch batteries have become the preferred solution for next-generation compact and high-performance applications.

What is a Pouch Battery Cell?

A pouch battery cell—also known as a lithium polymer (LiPo) pouch cell—is a type of lithium-ion battery that uses a flexible aluminum-laminated film casing instead of a rigid metal shell. This soft, lightweight packaging allows the battery to take on various shapes and thicknesses, making it ideal for compact or irregularly shaped devices.

Advantages of Pouch Battery Cell

- High Energy Density – Without a rigid metal casing, pouch cells pack more active materials into less space, offering higher energy per gram.

- Lightweight Design – The flexible aluminum-laminated film reduces weight, making them ideal for portable and compact devices.

- Customizable Shape and Size – Easy to tailor in thickness, dimensions, and capacity to fit unique product designs.

- Space Efficiency – Maximizes usable space within the device, ideal for slim or irregular layouts.

What is a Cylindrical Lithium ion Cell?

A cylindrical lithium-ion cell is one of the most common battery formats, featuring a round metal casing that houses the electrode materials wound into a tight spiral, or “jelly roll.” This design provides excellent mechanical stability and consistent performance, which is why cylindrical cells—such as the 18650 and 21700 types—are widely used in power tools, e-bikes, and electric vehicles.

Their metal shell offers strong protection against physical stress and helps with heat dissipation, making them durable and reliable under high-load conditions. However, the fixed cylindrical shape limits design flexibility and can reduce space efficiency compared to pouch cells.

Advantages of Cylindrical Lithium-Ion Cell

- High Mechanical Strength – The metal casing provides excellent protection against pressure, impact, and vibration.

- Stable and Mature Technology – Widely used and well-tested design ensures reliable performance and easy scalability.

- Cost-Effective Production – Standardized manufacturing makes cylindrical cells more affordable for large-scale applications.

What is a Prismatic Cell?

A prismatic lithium-ion cell is a type of battery that uses a rectangular or square metal casing to enclose flat electrode layers stacked together. This design allows for high capacity in a compact form factor, making prismatic cells common in applications like electric vehicles (EVs), energy storage systems, and large battery packs.

Advantages of Prismatic Cell?

- Efficient Use of Space – Prismatic cells feature a rectangular form that maximizes the use of available space, making them ideal for devices with size constraints.

- Easy Stackability – The flat structure allows cells to be stacked efficiently, enabling the construction of high-energy-density battery packs.

- Improved Thermal Management – The flat design promotes better heat dissipation, enhancing the overall thermal performance and stability of the battery.

Comparison: Pouch vs Cylindrical vs Prismatic

| Feature | Pouch Cell | Cylindrical Cell | Prismatic Cell |

|---|---|---|---|

| Shape & Structure | Soft, flexible foil pouch | Rigid round metal casing | Rectangular metal casing |

| Energy Density | High | Medium | Medium–High |

| Weight | Lightest | Heavier | Heavy |

| Space Efficiency | Excellent – fits compact or irregular designs | Moderate – gaps between cells | Good – flat and space-saving |

| Mechanical Strength | Requires external protection | Very strong and durable | Strong, but heavier |

| Thermal Performance | Good | Excellent | Good |

| Design Flexibility | Highly customizable in shape and size | Fixed cylindrical size | Limited flexibility |

| Manufacturing Cost | Moderate | Low (mass production) | Higher |

| Cycle Life | Good | Long | Good |

| Best For | Wearables, drones, robotics | Power tools, e-bikes, industrial use | EVs, energy storage systems |

How to Choose the Right Cell Type?

Choosing the right lithium-ion cell depends on your application requirements, device size, and performance priorities. Here’s a simple guide:

- Pouch Cells – Ideal for compact, lightweight, and irregularly shaped devices such as drones, wearables, robotics, and medical electronics. Their high energy density and customizable form factor make them perfect for designs where every millimeter counts.

- Cylindrical Cells – Best for applications requiring robustness, durability, and cost efficiency, such as power tools, e-bikes, and industrial equipment. Their mature technology and strong mechanical casing ensure long cycle life and stable performance.

- Prismatic Cells – Suitable for high-capacity, space-efficient applications like electric vehicles and energy storage systems. Their flat, stackable design maximizes volumetric efficiency while maintaining reliable thermal performance.

Ultimately, the choice comes down to your device requirements and design constraints. For products that need a balance of high energy, compact size, and custom fit, custom pouch battery solutions often provide the optimal solution.

Custom Pouch Battery Solutions from LanDazzle

LanDazzle specializes in custom pouch battery solutions tailored to meet your unique device requirements. Whether you need specific shapes, sizes, voltages, or capacities, our advanced design and manufacturing capabilities ensure a perfect fit for your application.

Our custom pouch batteries are ideal for a wide range of applications, including wearables, medical devices, and robotics. By leveraging our stacked-layer (lamination) technology, we maximize energy density while maintaining safety and reliability.

With LanDazzle, you benefit from:

- Flexible design options to match even the most compact or irregular devices

- High-quality cells and strict quality control for consistent performance

- Expert technical support to guide you from design to production

Conclusion

Choosing the right lithium-ion cell—pouch, cylindrical, or prismatic—is critical for achieving optimal performance, reliability, and design efficiency in your device. Each type offers unique advantages: pouch cells for lightweight, compact, and customizable solutions; cylindrical cells for durability and cost efficiency; and prismatic cells for high-capacity, space-efficient applications.

For products that demand high energy density, design flexibility, and tailored performance, custom pouch batteries from Lan Dazzle provide the ideal solution. Our expertise in advanced lamination technology and quality manufacturing ensures your battery fits perfectly with your device, delivering both safety and efficiency.

📩 Contact LanDazzle today to discuss your custom pouch battery needs and discover how our solutions can enhance your product.

Email: info@landazzle.com

Whatsapp: +8618938252128

Related Articles: