- Home

- »

- Service

Customization

Progress

The process begins when a customer submits an inquiry to our company, expressing interest in our products or a specific solution. We carefully review the customer’s requirements, including product specifications, quantity, and delivery timeline, to lay the foundation for the next steps.

Once we receive the inquiry, our team evaluates the customer’s needs by assessing the feasibility and determining the technical requirements, production capabilities, and delivery timeframes. During this stage, we also engage in initial discussions with the customer to ensure alignment on product expectations and requirements.

Confirming the product specifications is a critical step to ensure the successful completion of the project. During this stage, we work closely with the customer to finalize the technical specifications, dimensions, features, materials, and other key details. This helps to prevent misunderstandings during production and ensures that all parties are on the same page.

Based on the confirmed specifications, we provide the customer with a detailed quotation. The quotation includes the unit price, delivery schedule, payment terms, and other relevant details. We ensure that all pricing is transparent and competitive, offering the best value to the customer.

Once the quotation is confirmed, we proceed with the sample production. The sample is produced according to the specifications agreed upon with the customer, ensuring that the final product meets their expectations. This sample is essential for verifying the design and functionality before moving on to mass production.

After the sample production and customer approval, we verify the final pricing. At this stage, we review any changes in material costs or other factors that could impact the price and provide an updated quote. This ensures that the customer is aware of the final price before proceeding with the full order.

Once the price and sample are confirmed, we establish a production schedule with the customer. This schedule includes timelines for material procurement, production, quality control, and packaging. We work closely with the customer to ensure that the production process runs smoothly and on time, keeping them informed of each phase’s progress.

After the production is completed, we prepare the product for shipment according to the customer’s requirements. Whether by air, sea, or land, we choose the most suitable shipping method to ensure that the products reach the customer in a timely and secure manner. We ensure smooth and reliable delivery to meet the customer’s expectations.

Custom Battery Pack Solutions

(Including BMS Integration)

At Landazzle, we recognize that each device has unique energy demands. Our custom battery pack solutions are designed to match your application’s specifications perfectly, ensuring optimized performance, extended lifespan, and enhanced safety. Our expert team also integrates advanced Battery Management Systems (BMS) into each design, managing critical functions like voltage regulation, safe charging, and temperature control. This makes our solutions ideal for industries such as wearable devices, medical technology, drones, and smart products.

Custom Shaped Battery Solutions

At Landazzle, we recognize that each device has unique energy demands. Our custom battery pack solutions are designed to match your application’s specifications perfectly, ensuring optimized performance, extended lifespan, and enhanced safety. Our expert team also integrates advanced Battery Management Systems (BMS) into each design, managing critical functions like voltage regulation, safe charging, and temperature control. This makes our solutions ideal for industries such as wearable devices, medical technology, drones, and smart products.

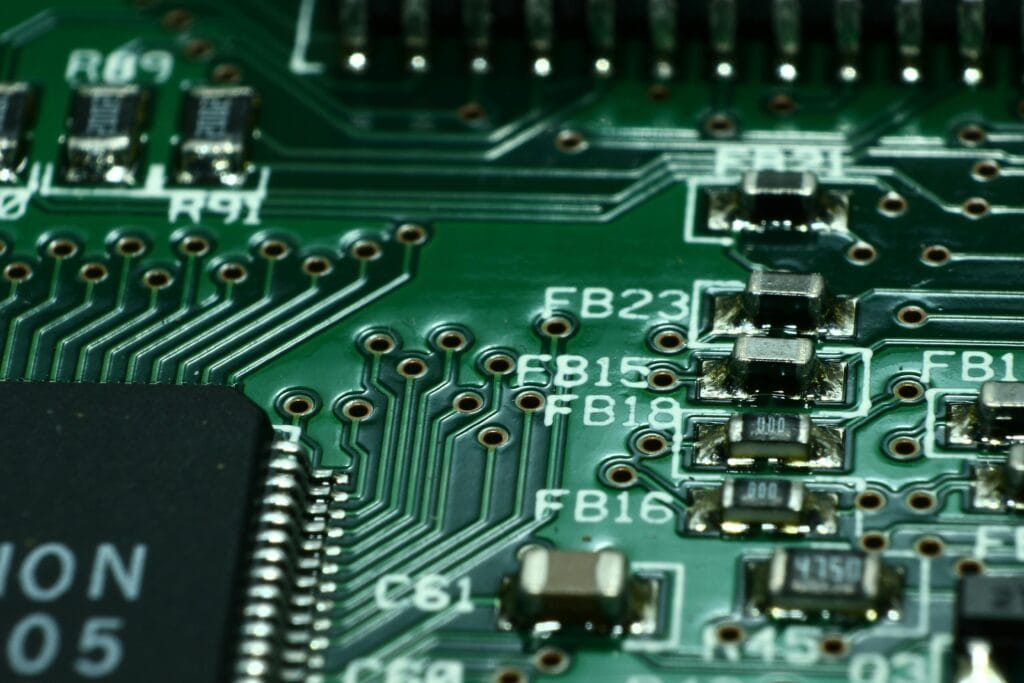

Rigorous Quality Control & Material Selection

Quality assurance is at the heart of everything we do at Landazzle. From material selection to final product delivery, we maintain the highest standards in battery manufacturing. Our batteries undergo stringent testing to ensure they meet crucial safety, performance, and durability benchmarks. We focus on key tests such as capacity validation, voltage stability, and safety protection features (e.g., overcharge and over-discharge protection). This guarantees that our battery solutions are safe, reliable, and efficient under real-world condition

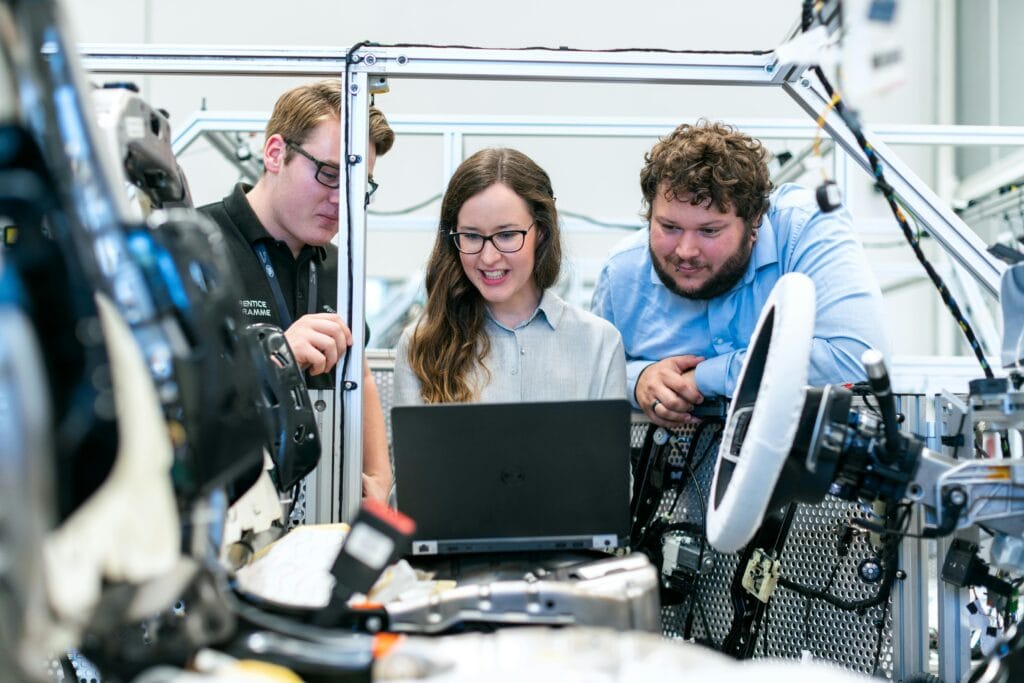

Technical Consultation & Support

At Landazzle, we offer more than just battery packs—we provide expert consultation to guide you through the complexities of battery design and integration. Our seasoned engineers assist in selecting the right battery chemistry, determining capacity needs, and ensuring proper integration of the Battery Management System (BMS). Whether you’re developing wearable tech, medical devices, or drones, we offer valuable insights into battery optimization, safety protocols, and regulatory compliance, ensuring your product is both efficient and market-ready.

WHY CHOOSE US FOR YOUR BATTERY SOLUTIONS?

- Experienced Engineering Team: With over 20 years in the battery industry, our engineers bring unmatched expertise to deliver cutting-edge solutions.

- Customized Solutions:

We specialize in crafting bespoke lithium-ion battery packs and BMS systems tailored to your exact specifications.

- Commitment to Quality:

Our rigorous quality control ensures safety, durability, and optimal performance.

- End-to-End Services:

From initial consultation to full integration, Landazzle provides complete solutions to help you succeed.

Get In Touch

Contact US

Let's Talk!

Looking for the perfect battery solution? Share your needs with us, and let’s explore how we can create something tailored just for you.

- info@landazzle.com

- +86 18938252128

- Building B, Songhu Yungu Dalang Innovation Industrial Park, No. 388 Yangxin Road, Dalang Town, Dongguan City