Table of Contents

What is a Pouch Battery?

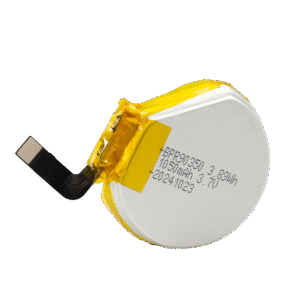

A pouch battery—also known as a lithium polymer (LiPo) pouch cell—is a type of lithium-ion battery that uses a flexible aluminum-laminated film casing instead of a rigid metal shell. This soft, lightweight packaging allows the battery to take on various shapes and thicknesses, making it ideal for compact or irregularly shaped devices.

1. Electrodes: Positive and Negative

The core of any pouch cell is its electrodes. The positive electrode (cathode) and negative electrode (anode) are made from active materials coated on metal foils. Common cathode materials include lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP), while graphite or silicon-based materials are typically used for the anode. The choice of electrode material directly impacts energy density, cycle life, and discharge performance.

2. Separator

A thin, porous layer called the separator keeps the anode and cathode from touching, preventing short circuits while allowing lithium ions to pass through freely. High-quality separators are critical for battery safety, performance, and long-term reliability.

3. Electrolyte

The electrolyte is a lithium-ion conductive solution that facilitates ion movement between electrodes. Its composition affects temperature performance, charge/discharge rates, and overall safety. Advanced electrolytes can enhance low-temperature performance or improve high-current stability.

4. Flexible Pouch Packaging

Unlike rigid cylindrical or prismatic cells, pouch batteries are encased in a flexible aluminum-laminated film. This packaging reduces weight, allows for custom shapes and sizes, and maximizes space utilization in compact devices. However, it also requires careful design to manage swelling and mechanical stress during charge and discharge cycles.

How to Make a Pouch Battery?

Creating a high-quality pouch battery involves precise engineering and advanced manufacturing processes. While the detailed steps cover electrode preparation, stacking or winding, electrolyte filling, sealing, and testing, the full process is best explored through our dedicated video and in-depth article.

For a step-by-step walkthrough of pouch battery production, including insights into custom designs and quality control, watch our video or read our full article: how a custom lipo battery is made?

Why Choose a Pouch Battery? Customization and Application Advantages

Pouch batteries offer unique benefits that make them ideal for modern electronic devices and specialized applications. Unlike cylindrical or prismatic cells, their flexible, lightweight packaging allows for efficient space utilization and a high energy-to-weight ratio, which is crucial for compact and portable devices.

1. Space-Efficient and Lightweight

The soft, flat design of pouch cells maximizes usable volume within a device, enabling slimmer, lighter products without compromising battery capacity. This makes them perfect for applications like wearable electronics, smart glasses, and portable medical devices.

2. Design Flexibility

One of the biggest advantages of pouch batteries is their adaptability. They can be manufactured in various shapes, sizes, and thicknesses to fit unique product requirements. Custom configurations are possible for curved surfaces, thin profiles, or multi-cell modules.

3. High Performance for Specialized Applications

Pouch batteries can be tailored for high-power output, extended runtime, and specific environmental conditions, such as low-temperature performance for drones or industrial equipment. They also allow integration of safety features, such as temperature sensors or protective circuits.

4. Customization for OEMs and Integrators

For OEMs and system integrators, pouch batteries provide the freedom to design products without being constrained by standard battery formats. LanDazzle specializes in delivering fully customized pouch battery solutions that meet precise voltage, capacity, and form-factor requirements.

5. Versatile Applications

From drones and robotics to electric tools, smart locks, and aerospace devices, pouch batteries offer a versatile solution that balances size, weight, and performance. Their modular design also supports battery packs and multi-cell assemblies for larger energy needs.

Comparison: Pouch vs Cylindrical vs Prismatic

| Feature | Pouch Cell | Cylindrical Cell | Prismatic Cell |

|---|---|---|---|

| Shape & Structure | Soft, flexible foil pouch | Rigid round metal casing | Rectangular metal casing |

| Energy Density | High | Medium | Medium–High |

| Weight | Lightest | Heavier | Heavy |

| Space Efficiency | Excellent – fits compact or irregular designs | Moderate – gaps between cells | Good – flat and space-saving |

| Mechanical Strength | Requires external protection | Very strong and durable | Strong, but heavier |

| Thermal Performance | Good | Excellent | Good |

| Design Flexibility | Highly customizable in shape and size | Fixed cylindrical size | Limited flexibility |

| Manufacturing Cost | Moderate | Low (mass production) | Higher |

| Cycle Life | Good | Long | Good |

| Best For | Wearables, drones, robotics | Power tools, e-bikes, industrial use | EVs, energy storage systems |

Challenges in Pouch Battery Design

1. Mechanical & Structural Challenges

- Swelling: Cells can bulge from gas build-up and material expansion during charging. This strains components and can break the seal.

- Puncture Risk: The soft, flexible pouch is easily damaged by sharp objects or crushing, leading to serious safety hazards.

- Seal Integrity: The edge seal is a weak point. If it fails, electrolyte can leak out, or moisture can get in, ruining the cell.

2. Electrical & Manufacturing Challenges

- Tab Design: Small metal tabs (the electrical contacts) can be a bottleneck for high current, causing heat and limiting fast charging.

- Stack Pressure: The internal layers need uniform pressure to work properly. Uneven pressure causes rapid aging.

- Complex Manufacturing: The assembly process is delicate and sensitive to moisture, making consistent quality hard to achieve.

Custom Pouch Battery Solutions from LanDazzle

We understand the challenges in pouch battery design and that’s why our custom solutions are engineered to address these issues while delivering optimal performance.

1. Advanced Mechanical Design

We optimize cell structure and materials to minimize swelling and reinforce packaging against punctures and external stress. Our precise sealing technology ensures long-term integrity, preventing leaks and protecting against environmental factors.

2. Electrical and Performance Optimization

Our engineers carefully design tab placement and thickness to support high-current applications, enabling fast charging and stable power output. We also ensure uniform stack pressure for consistent performance and extended cycle life.

3. Tailored for Your Application

Whether it’s a drone, robotic system, wearable device, or industrial tool, we customize pouch cells to meet specific voltage, capacity, size, and shape requirements. Low-temperature performance, high-power output, and integrated BMS solutions are all available to match your exact needs.

4. Quality and Reliability

Every battery undergoes strict quality control, including moisture-sensitive assembly, thermal management, and mechanical testing, ensuring reliable operation even in demanding conditions.

Conclusion

Pouch batteries have revolutionized modern electronics by offering a flexible, lightweight, and high-performance energy solution. Their adaptability in shape, size, and capacity makes them ideal for applications ranging from drones and robotics to wearable devices and aerospace systems. While challenges such as swelling, puncture risk, and manufacturing complexity exist, advanced design and engineering—like the custom solutions provided by LanDazzle—ensure these batteries deliver reliable performance, safety, and longevity. By choosing a tailored pouch battery solution, OEMs and integrators can maximize device efficiency, optimize space, and meet the specific demands of their unique applications.

Contact LanDazzle today to discuss your custom pouch battery needs and discover how our solutions can enhance your product.

Email: info@landazzle.com

Whatsapp: +8618938252128