Giriş: Taşınabilir İnovasyonun Güç Merkezi

Giderek birbirine bağlanan ve taşınabilir hale gelen dünyamızda, Li Polimer piller sayısız cihaza güç sağlayan isimsiz kahramanlar olarak ortaya çıkmıştır. Cebinizdeki akıllı telefondan tepenizde süzülen sofistike dronlara ve hayat kurtaran tıbbi ekipmanlara kadar, bu hafif, yüksek enerji yoğunluklu güç hücreleri her yerde bulunmaktadır. Lityum Polimer (LiPo) piller, sıvı yerine polimer elektrolit kullanan, esnek form faktörlerine ve mükemmel güç dağıtımına olanak tanıyan bir tür şarj edilebilir lityum-iyon pildir. Bu benzersiz yapı, onları alan ve ağırlığın kritik olduğu uygulamalar için son derece uygun hale getirerek tüketici elektroniği, giyilebilir cihazlar ve hatta özel endüstriyel aletlerde tasarım ve işlevselliğin sınırlarını zorlamaktadır.

Ve bu kritik bileşenlerin küresel tedariki söz konusu olduğunda, Çin tartışmasız bir lider konumundadır. Geniş üretim altyapısı, derin yetenek havuzu ve araştırma-geliştirmeye yaptığı önemli yatırımlarla Çin, otomotiv sektörünün en önemli merkezi haline gelmiştir. En iyi Li Polimer pil tedarikçileri. Bu makale, karmaşık bir ortamda gezinmek için kesin rehberiniz olarak hizmet vermektedir. Çin'in önde gelen LiPo pil üreticileriyeteneklerini vurgulayarak, doğru iş ortağını seçmek için önemli faktörleri vurgulayarak ve nihayetinde yeniliklerinizi ileriye taşıyacak stratejik işbirlikleri kurmanıza yardımcı olur.

Çin'deki Li Polimer Pil Ortamını Anlamak

Çin'in akü endüstrisinin büyüklüğü ve karmaşıklığı dikkat çekicidir. Bu sadece hacimle ilgili değil; yenilikçiliği ve verimliliği teşvik eden kapsamlı bir ekosistemle ilgili.

Çin LiPo Pil Pazarında Neden Lider?

Çin'in Avrupa'daki hakimiyeti LiPo pil pazarı tesadüfi değildir; stratejik planlama ve aralıksız uygulamanın sonucudur. Ülke, benzersiz bir pil üretim kapasitesiDünya güç bataryası üretim kapasitesinin 70%'sinden fazlasını oluşturmaktadır. Bu liderlik birkaç kilit faktör tarafından desteklenmektedir:

- Üretim Ölçeği: Çinli üreticiler, maliyetleri düşüren ve verimliliği artıran ölçek ekonomilerini mümkün kılan, dünya çapında eşi benzeri olmayan bir ölçekte faaliyet göstermektedir. Bu devasa üretim, hem gelişen elektronik ve elektrikli araç sektörlerinden gelen iç talebi hem de önemli ihracat pazarlarını karşılamaktadır.

- Ar-Ge'ye Yatırım: Çin hükümeti ve önde gelen şirketler, Çin'in kalkınması için önemli kaynaklar aktarıyor. Batarya Ar-Ge'sisınırlarını zorlayarak batarya teknoloji̇si̇ geli̇şti̇rme. Buna gelişmiş malzeme bilimi, yeni batarya kimyaları ve sofistike üretim süreçleri de dahildir.

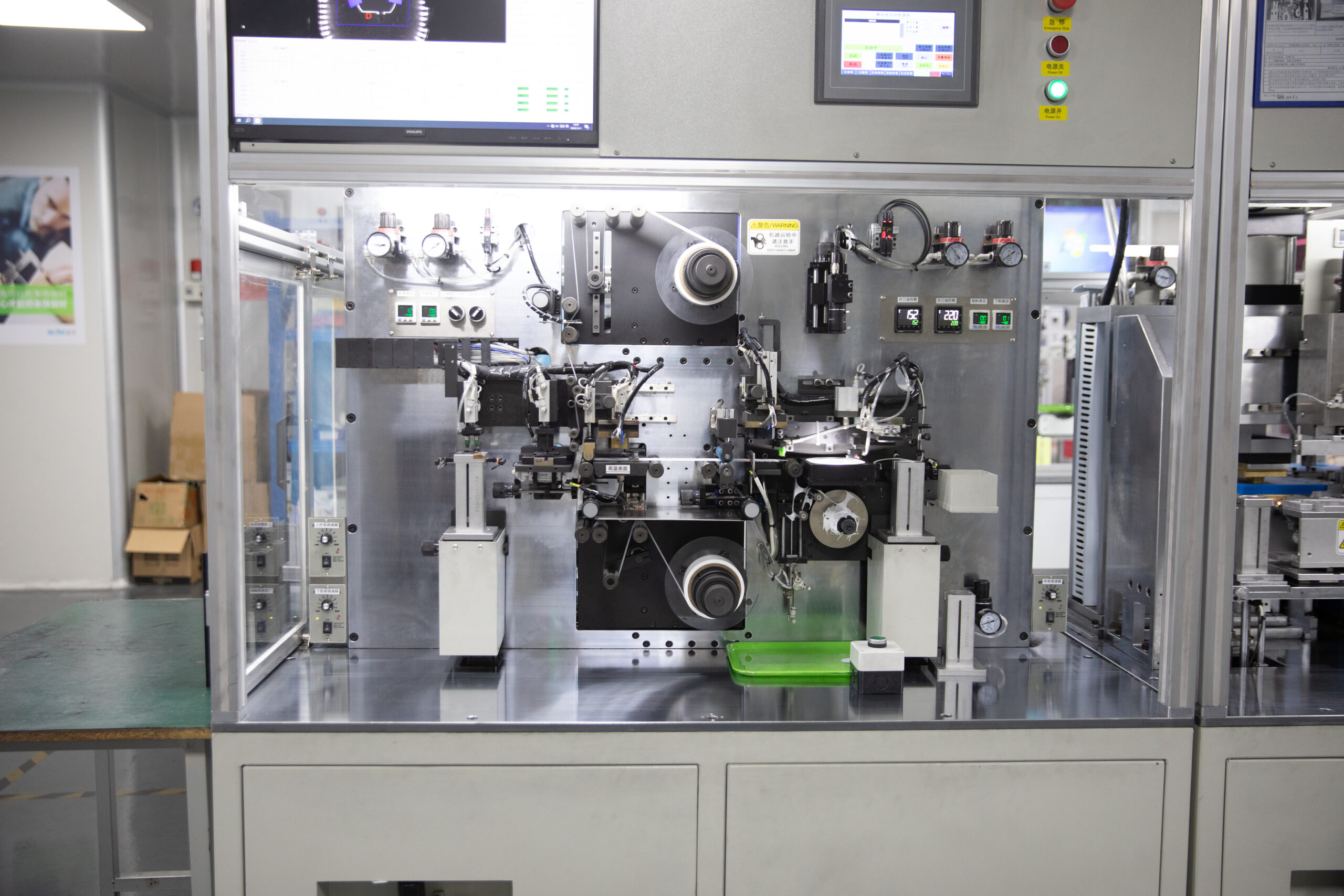

- İleri İmalat Altyapısı: Çin, üretimde hassasiyet, tutarlılık ve yüksek verim sağlayan son teknoloji ürünü otomatik üretim hatlarına büyük yatırımlar yapmıştır. LiPo pil imalat.

- Sağlam Tedarik Zinciri: Hammadde çıkarma ve işlemeden hücre montajı ve batarya paketi entegrasyonuna kadar entegre ve olgun bir tedarik zinciri, Çinli tedarikçilere belirgin bir rekabet avantajı ve üretim üzerinde daha fazla kontrol sağlamaktadır.

- Rekabetçi Fiyatlandırma: Kalitenin her zaman her şeyden önemli olması gerekirken, Çin'deki rekabet ortamı ve üretim ölçeği genellikle daha uygun maliyetli LiPo tedariki fırsatlar.

En İyi LiPo Akülerin Temel Özellikleri

Değerlendirirken LiPo pil performansı, birkaç kritik özellik kaliteyi ve belirli uygulamalar için uygunluğu tanımlar:

- Yüksek Enerji Yoğunluğu (Wh/kg): Bu, bir pilin birim ağırlık başına ne kadar enerji depolayabileceğini ifade eder. Üst LiPo piller üstün enerji yoğunluğu sunarak cihazların daha küçük, daha hafif olmasını ve daha uzun süre çalışmasını sağlar.

- Uzun Çevrim Ömrü: Bir pilin kapasitesi önemli ölçüde düşmeden önce kaç şarj-deşarj döngüsüne maruz kalabileceğini gösteren önemli bir ölçüttür. Yüksek kaliteli LiPo piller, kullanıma ve kimyaya bağlı olarak 500 ila 2000'den fazla döngü sunabilir.

- Düşük Kendi Kendine Deşarj Oranı: İyi LiPo piller, kullanılmadıkları zamanlarda şarjlarını verimli bir şekilde koruyarak ihtiyaç duyulduğunda hazır olmalarını sağlar.

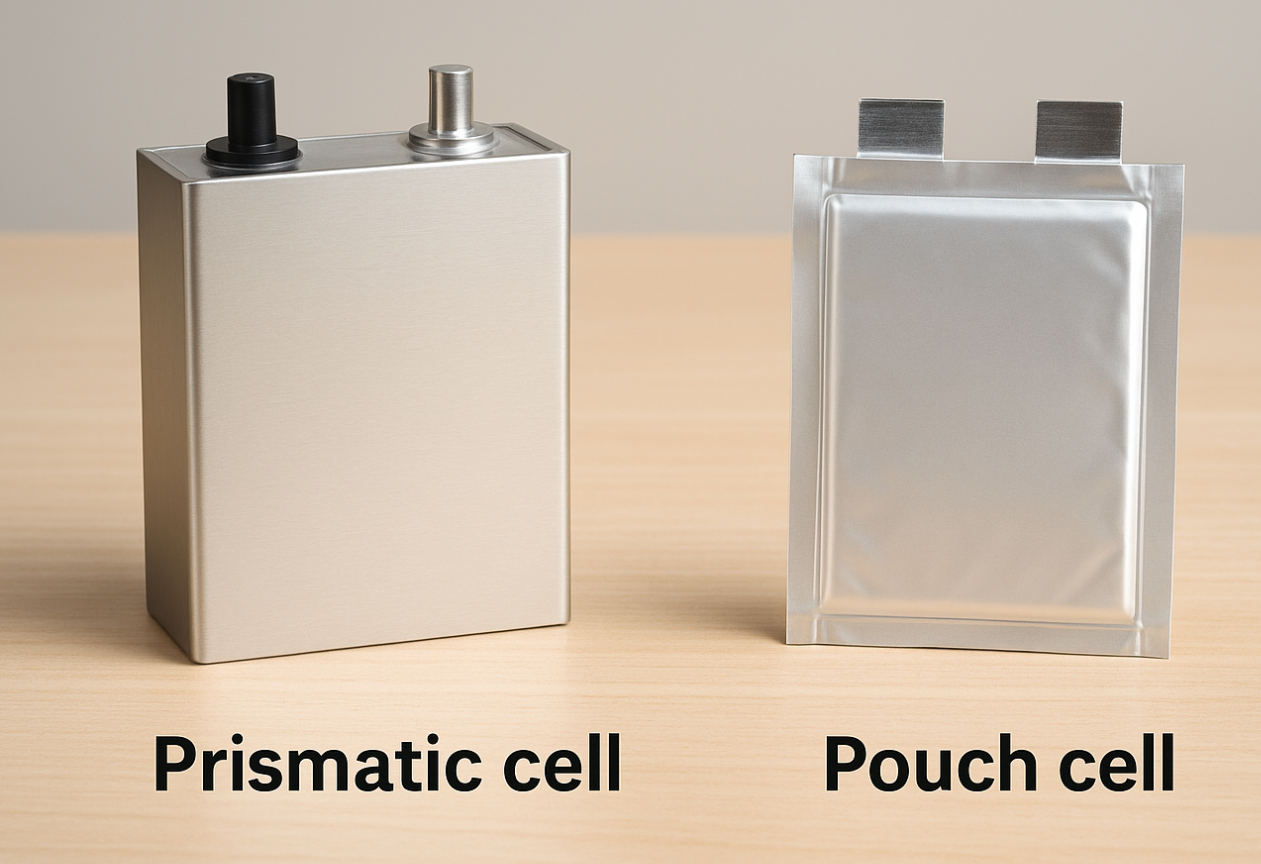

- Esnek Form Faktörleri: Sert silindirik veya prizmatik hücrelerin aksine, esnek LiPo Bataryalar, ultra ince veya kavisli cihazlar da dahil olmak üzere benzersiz ürün tasarımlarına uyacak şekilde çeşitli şekil ve boyutlarda üretilebilir.

- Geliştirilmiş Güvenlik Özellikleri: Saygın LiPo pil üreticileri Aşırı şarj, aşırı deşarj, kısa devre ve aşırı ısınmayı önlemek için Koruma Devresi Modülleri (PCM'ler) ve termal yönetim sistemleri gibi çoklu güvenlik mekanizmalarını entegre ederek akü güvenli̇ği̇.

Çin'in Önde Gelen Li Polimer Pil Tedarikçilerine Dikkat

Çok sayıda Çinli pil devleri ürkütücü olabilir. Burada, en etkili ve güvenilir olanlardan bazılarını vurguluyoruz LiPo pil tedarikçileri kalite, yenilikçilik ve üretim kabiliyetleri konusunda güçlü bir üne sahiptir.

1. Kademe Devler

Bu şirketler, muazzam üretim kapasiteleri ve gelişmiş Ar-Ge çalışmalarıyla küresel batarya endüstrisinin ön saflarında yer almaktadır. Bazıları en çok elektrikli araç (EV) bataryaları ile tanınsa da, teknolojileri ve ölçekleri genellikle çeşitli uygulamalar için LiPo sektöründe önemli yeteneklere dönüşür.

- CATL (Contemporary Amperex Technology Co. Limited): Her ne kadar öncelikle bir dev güç bataryası teknolojisi (2024'ün başlarında yaklaşık 37,7% ile EV bataryaları için en büyük küresel pazar payına sahip), CATL'nin kapsamlı Ar-Ge ve üretim becerisi, enerji depolama sistemleri ve diğer yüksek talep gören uygulamalar için yüksek performanslı LiPo çözümlerine kadar uzanmaktadır. Son teknoloji pil yönetim sistemleri (BMS) ve gelecekteki LiPo türevlerini etkileyebilecek sodyum-iyon piller gibi gelişmiş teknolojileri keşfetmek de dahil olmak üzere pil kimyalarında sürekli yenilikleriyle tanınırlar.

- BYD Company Limited: Oldukça çeşitlendirilmiş bir teknoloji şirketi olan BYD, hem elektrikli araçlar hem de LiPo pil üretimi tüketici elektroniği ve enerji depolama için. Hammaddeden bitmiş ürünlere kadar entegre yaklaşımları, onlara benzersiz bir rekabet avantajı ve sağlam bir tedari̇k zi̇nci̇ri̇ esnekli̇ği̇. BYD, 2024'ün başlarında küresel elektrikli araç akü pazarında 15,4%'lik önemli bir paya sahipti ve bu da geniş üretim kapasitesini ortaya koyuyordu.

- EVE Enerji A.Ş., Ltd: EVE Energy, güçlü bir odaklanma ile hızla büyüyen küresel bir oyuncudur LiPo pil geniş bir uygulama yelpazesinde geliştirme. Ar-Ge'ye yaptıkları önemli yatırımlar ve agresif büyümeleriyle tanınan şirket, 2024'ün başlarında pil tüketiminde 53,2%'lik kayda değer bir artış oranı yaşadı.

- CALB (China Aviation Lithium Battery Co., Ltd.): Bir yüksek teknoloji kuruluşu olarak CALB, büyük üretim kapasiteleri kurarak ve küresel varlığını genişleterek önemli ölçüde büyüdü. Elektrikli araç akü segmentinde önemli bir güç (2024'ün başlarında yaklaşık 4,3% küresel pazar payı ile) olan CALB'nin gelişmiş lityum teknolojilerindeki uzmanlığı, çeşitli zorlu uygulamalar için uygun yüksek kaliteli LiPo hücrelerine dönüşmektedir.

Gelişmekte Olan ve Uzmanlaşmış LiPo Üreticileri

Devlerin ötesinde, uzmanlaşmış üreticilerden oluşan canlı bir ekosistem, genellikle daha fazla esneklik ve niş uzmanlık sunarak belirli ihtiyaçlara hitap eder.

- Grepow Bataryası: Yüksek deşarj oranlı pilleriyle tanınan Grepow, aşağıdaki gibi güç patlaması gerektiren uygulamalar için tercih edilir drone bataryası üreticileri ve uzaktan kumandalı cihazlar. Benzersiz konfigürasyonlara sahip özel pil paketleri üretme konusunda mükemmeldirler.

- Ace Battery: Ace Battery, OEM/ODM projelerinde müşterileriyle yakın işbirliği içinde çalışmakta ve farklı endüstriler için çeşitli hücre kimyaları ve paket tasarımları konusunda uzmanlık sağlamaktadır.

- Delong Enerji: Bu şirket, uluslararası sertifikasyonlara verdiği önem ve geniş standart ve özel ürün yelpazesi ile öne çıkmaktadır. LiPo piller titiz güvenlik ve kalite kriterlerini karşılamaktadır.

- LanDazzle: LanDazzle tasarım ve üretim konusunda uzmanlaşmıştır özel şekilli piller Son teknoloji endüstrilerin benzersiz taleplerine uyacak şekilde. İle 20+ akü uzmanı ve 200'den fazla profesyonelden oluşan küresel bir ekiple tıbbi cihazlar, tüketici elektroniği ve giyilebilir teknoloji için hassas mühendislik çözümleri sunuyoruz.

En İyi Tedarikçileri Farklılaştıran Nedir?

En iyisi LiPo pil tedarikçileri kendilerini farklılaştırırlar:

- Otomasyona Yatırım: Yüksek otomasyonlu üretim hatları insan hatasını en aza indirir ve tutarlı kalite ve hassasiyet sağlar.

- Titiz Kalite Kontrol: Hammadde denetiminden nihai ürün testine kadar çok aşamalı kalite kontrollerinin uygulanması güvenilirlik ve emniyet sağlar.

- Güçlü Ar-Ge Yetenekleri: Sürekli yeniliğe bağlılık, keşfetme geli̇şmi̇ş batarya ki̇myasallari ve yeni nesil tasarımlar.

- Kapsamlı Test: Sıkı iç ve uluslararası kurallara bağlılık akü test protokolleri̇ çeşitli koşullar altında performans ve güvenliği garanti etmek için.

- Olağanüstü Müşteri Desteği: Duyarlı iletişim, teknik destek ve satış sonrası hizmet, güvenilir bir şirketin ayırt edici özellikleridir. akü ortaği.

- Etik Kaynak Kullanımı: Hammaddelerin şeffaf ve sorumlu bir şekilde tedarik edilmesine, çevre ve işgücü ile ilgili kaygıların ele alınmasına giderek daha fazla önem verilmesi tedarik zinciri şeffaflığı.

Çin'de LiPo Tedarikçisi Seçerken Önemli Faktörler

Doğru seçimi yapmak Çinli LiPo pil tedarikçisi ürün performansını, güvenliği ve pazar başarısını etkileyen stratejik bir karardır. İşte öncelik vermeniz gerekenler:

Kalite ve Sertifikalar

Bu pazarlık konusu değildir. Her zaman aşağıdakileri sağlayan tedarikçilere öncelik verin LiPo pil sertifikaları küresel olarak tanınmış kuruluşlardan. Bu sertifikalar sizin güvenlik ve uyumluluk güvencenizdir.

- IEC 62133: Bu uluslararası standart, taşınabilir uygulamalarda kullanılmak üzere taşınabilir sızdırmaz ikincil lityum hücrelerin ve pillerin güvenliği için gereklilikleri belirtir. Aşırı şarj, harici kısa devre, serbest düşme, termal suistimal ve mekanik şok dahil olmak üzere temel güvenlik testlerini kapsar.

- UL 1642 / UL 2054: Underwriters Laboratories (UL) sertifikaları Kuzey Amerika pazarları için kritik öneme sahiptir. UL 1642 özellikle lityum pil hücrelerinin güvenliğini ele alırken, UL 2054 pil paketlerini kapsar. Bunlar yangın, patlama ve elektrik tehlikelerine karşı sıkı testleri içerir.

- BM 38.3: için zorunludur lityum pillerin nakliyesi ve taşınması hava, deniz veya kara yoluyla. Bir dizi test içerir (T1-T8) irtifa simülasyonu, termal testler, titreşim, şok, harici kısa devre, darbe, aşırı şarj ve zorunlu deşarj gibi, değişen taşıma koşulları altında akünün stabilitesini sağlamak. Seçtiğiniz herhangi bir tedarikçi UN 38.3 uyumlu.

- CE, RoHS, MSDS: CE işareti Avrupa sağlık, güvenlik ve çevre koruma standartlarına uygunluğu gösterir. RoHS (Tehlikeli Maddelerin Kısıtlanması) tehlikeli maddeleri sınırlandırır. MSDS (Malzeme Güvenlik Bilgi Formu) güvenli kullanım için önemli bilgiler sağlar.

- ISO 9001: Bu kalite yönetim sistemi sertifikası, tedarikçinin tutarlı kalite için sağlam bir sisteme sahip olduğunu gösterir. İstek fabri̇ka deneti̇mleri̇ süreçlerini doğrulamak için de ihtiyatlı bir adımdır.

Ar-Ge ve İnovasyon Yetenekleri

İleri görüşlü bir tedarikçi aşağıdakilere yatırım yapar Batarya Ar-Ge'si ve farkında batarya teknoloji̇si̇ trendleri̇. Ar-Ge ekipleri, patent portföyleri ve endüstri konsorsiyumlarına katılımları hakkında bilgi alın. Şu alanlardaki çabalarına bakın:

- Yeni Malzeme Geliştirme: Daha yüksek enerji yoğunluğu için silikon anotların veya daha fazla güvenlik için katı hal elektrolitlerinin araştırılması.

- Gelişmiş Batarya Yapıları: Gelişmiş performans ve termal yönetim için hücre tasarımında yenilikler.

- Daha Hızlı Şarj Teknolojileri: Bozulma olmaksızın daha yüksek şarj akımlarını kabul edebilen bataryaların geliştirilmesi.

- Katı Hal Batarya Geliştirme: Seri üretim için henüz gelişmekte olan bu alanda faaliyet gösteren tedarikçiler, teknolojilerini geleceğe hazırlama konusundaki kararlılıklarını göstermektedir.

Üretim Kapasitesi ve Ölçeklenebilirlik

Tedarikçinin mevcut ve gelecekteki üretim taleplerinizi karşılayabileceğinden emin olun. Tartışın:

- Minimum Sipariş Miktarları (MOQ'lar): MOQ'ları üretim ölçeğinizle uyumlu mu?

- Teslim Süreleri: Numuneler, prototipler ve seri üretim siparişleri için tipik teslim süreleri nelerdir?

- Özel Siparişler için Esneklik: Üretim hatlarını sizin benzersiz ürünlerinize uyarlayabilirler mi? OEM LiPo veya ODM akü hizmetleri gereksinimleri?

Maliyet-Etkinlik vs Kalite

Çinli tedarikçiler rekabetçi fiyatlar sunarken, "çok ucuz" bir kırmızı bayrak olabilir. Öncelik verin kalite vs. fiyat. Standartların altında bir akü için daha düşük bir ön maliyet, uzun vadede daha yüksek maliyetlere yol açabilir:

- Performans Sorunları: Daha kısa kullanım ömrü, daha düşük kapasite veya tutarsız çıktı.

- Güvenlik Riskleri: Aşırı ısınma, şişme ve hatta yangın potansiyeli, ürün geri çağırmalarına ve itibar kaybına yol açabilir.

- Garanti ve İadeler: Hatalı ürünlerle uğraşmak lojistik ve mali bir kabus olabilir. Odaklanın toplam sahip olma maliyetiBu da güvenilirlik ve uzun ömürlülüğü içerir.

Tedarik Zincirinde Şeffaflık ve Etik Uygulamalar

Birçok işletme için, etik pil tedariki ve sürdürülebi̇li̇r üreti̇m giderek daha önemli hale gelmektedir. Hakkında bilgi alın:

- Hammadde Tedariki: Lityum, kobalt ve diğer malzemelerin sorumlu bir şekilde ve çatışma olmadan tedarik edilmesini nasıl sağlıyorlar?

- Çevresel Uyumluluk: Üretim süreçlerinde çevresel düzenlemelere uyuyorlar mı?

- İşgücü Uygulamaları: Adil çalışma standartlarını koruyorlar mı? Şeffaf bir tedarikçi bu hususlara ilişkin ayrıntıları vermeye istekli olacaktır.

Müşteri Hizmetleri ve Destek

Özellikle uluslararası tedarikçilerle çalışırken etkili iletişim çok önemlidir. Onları değerlendirin:

- Duyarlılık: Soru ve endişelere ne kadar hızlı yanıt veriyorlar?

- Teknik Destek: Batarya entegrasyonu ve performansı konusunda uzman rehberlik sağlayabilecek bilgili mühendisleri var mı?

- Satış Sonrası Hizmet: Satın alma sonrası sorunların giderilmesine yönelik garanti politikaları ve prosedürleri nelerdir? A güveni̇li̇r müşteri̇ hi̇zmetleri̇ ekibi operasyonlarınızı önemli ölçüde kolaylaştırabilir.

Li Polimer Bataryaların Geleceği ve Çin'in Rolü

Manzara batarya teknoloji̇si̇ sürekli gelişiyor ve Çin'in batarya inovasyonu bu ilerlemelerin ön saflarında yer almaktadır. Bu alanda sürekli atılımlar görmeyi bekleyebiliriz LiPo pil performansı da dahil olmak üzere:

- Daha Yüksek Enerji Yoğunluğu: Daha küçük ve daha hafif cihazların daha uzun çalışma sürelerine sahip olmasını sağlar.

- Daha Hızlı Şarj: Pil ömründen veya güvenliğinden ödün vermeden şarj sürelerini önemli ölçüde azaltan yenilikler.

- Geliştirilmiş Güvenlik: Riskleri azaltmak için termal yönetim ve elektrolit stabilitesinde devam eden iyileştirmeler.

- Katı Hal Bataryalarının Ortaya Çıkışı: Halen geliştirme aşamasında olan katı hal LiPo varyasyonları, sıvı elektrolitleri katı olanlarla değiştirerek güvenlik ve enerji yoğunluğunda devrim niteliğinde sıçramalar vaat ediyor.

- Kobalt İçermeyen Kimyasallar: Daha sürdürülebilir ve etik kaynaklı malzemelere yönelmek.

- Esnek ve Giyilebilir Tasarımlar: Yeni nesil giyilebilir ve IoT cihazları için ultra ince, bükülebilir ve hatta gerilebilir LiPo pillerin daha da geliştirilmesi.

Çin'in güçlü Ar-Ge altyapısı ve muazzam üretim kabiliyetleri, bu gelişmeleri yönlendirmek için onu mükemmel bir şekilde konumlandırıyor ve Çin'in küresel bir lider olarak kalmasını sağlıyor. LiPo'nun geleceği ve batarya teknoloji̇si̇ trendleri̇. Bu da LiPo'ya bel bağlayan sektörlerin Çin'den çıkan son teknoloji çözümlerden faydalanmaya devam edeceği anlamına geliyor.

Sonuç: Çin LiPo Excellence ile İlerlemenize Güç Katmak

Seçme en iyi LiPo tedarikçileri Çin'den tedarik etmek, kapsamlı araştırma ve durum tespiti gerektiren kritik bir karardır. Pazar dinamiklerini anlayarak, üst düzey üreticilerin özelliklerini tanıyarak ve kalite, sertifikalar, yenilik ve destek gibi faktörleri titizlikle değerlendirerek işletmeler güçlü ve güvenilir ortaklıklar kurabilir.

Çin'in inkar edilemez liderliği LiPo pil Ölçeği, teknolojik becerisi ve rekabetçi ortamıyla dikkat çeken üretim, yüksek performanslı, uygun maliyetli ve özelleştirilmiş güç çözümleri arayan küresel işletmeler için benzersiz fırsatlar sunmaktadır. Dikkatli bir seçimle, aşağıdakilerden güvenle kaynak sağlayabilirsiniz Çin LiPo endüstri liderleri ve güveni̇li̇r ortaklar gelecek yıllarda yeniliklerinize ve ilerlemenize güç katacak.