Inside the Power Pouch: Unpacking the Materials That Make Up Pouch Cells

In our increasingly mobile and technologically driven world, the demand for efficient and lightweight power sources has skyrocketed. From the sleek smartphone in your pocket to the powerful electric vehicle on the road, pouch cells have emerged as a dominant force in battery technology. Their flexible design and high energy density make them a preferred choice for a vast array of applications. But what exactly are these ubiquitous power sources made of? Join us as we delve deep into the material science behind the pouch cell battery, exploring the intricate components that enable them to store and deliver energy.

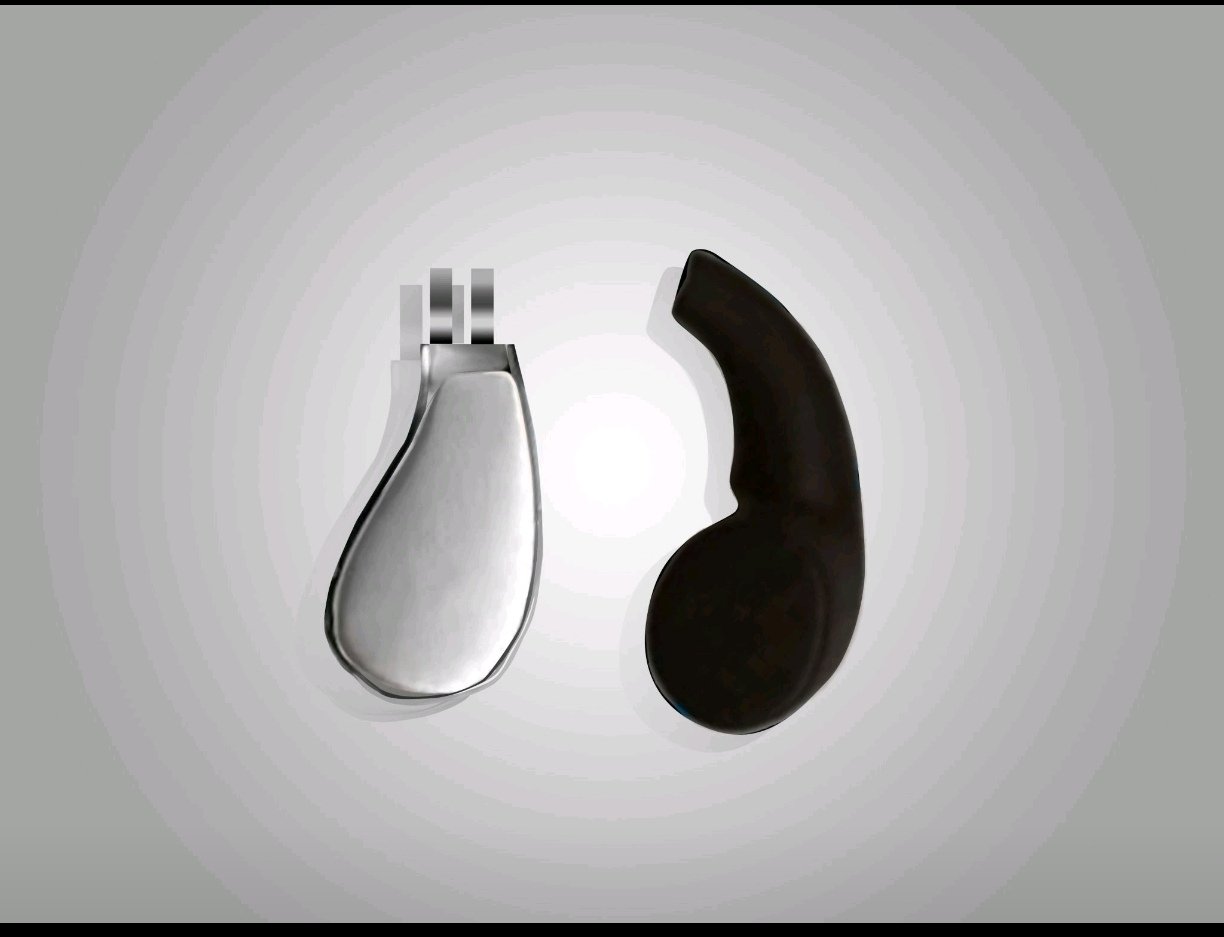

At its core, a battery pouch is a type of lithium-ion battery characterized by its flexible, sealed packaging, typically made of an aluminum laminate. This design distinguishes it from rigid cylindrical or prismatic cells. However, the magic truly lies within the materials that constitute its internal structure. Let’s break down the key components of a li ion battery pouch.

The Cathode: The Positive Powerhouse

The cathode is the positive electrode where lithium ions are stored when the battery is discharged and released during charging. The choice of cathode material significantly impacts the energy density, power output, and lifespan of the lithium battery pouch. Several materials are commonly employed:

- Lithium Cobalt Oxide (LCO): Known for its high energy density, LCO is often found in consumer electronics like smartphones and laptops.

- Lithium Manganese Oxide (LMO): Offering a lower cost and improved safety compared to LCO, LMO has a moderate energy density.

- Lithium Nickel Manganese Cobalt Oxide (NMC): Striking a balance between energy, power, and safety, NMC is a popular choice for electric vehicles and power tools. Different NMC formulations (e.g., NMC 111, NMC 532, NMC 811) offer varying performance characteristics.

- Lithium Nickel Cobalt Aluminum Oxide (NCA): Providing high energy density and good power, NCA is used in some high-performance electric vehicles.

- Lithium Iron Phosphate (LFP): Renowned for its exceptional safety and long cycle life, LFP is gaining traction in electric vehicles and energy storage systems despite having a lower energy density than other options.

These active materials are typically mixed with a conductive additive, such as carbon black, to enhance electron flow, and a binder, like polyvinylidene fluoride (PVDF), to adhere the materials to the current collector. The cathode is coated onto a thin aluminum foil, which acts as the current collector.

The Anode: The Negative Charge Carrier

The anode is the negative electrode where lithium ions are stored during charging and released during discharge. The most common anode material in a lithium ion battery pouch cell is graphite. Its layered structure allows for efficient intercalation and deintercalation of lithium ions, offering a good balance of cost, cycle life, and energy density.

However, to further enhance energy density, researchers and manufacturers are increasingly incorporating silicon into the anode. Silicon has a much higher theoretical lithium storage capacity than graphite. Silicon composite anodes, where silicon is combined with graphite or other carbon materials, are becoming more prevalent in advanced pouch battery cell designs. While silicon expands significantly during lithium ion insertion, which can lead to mechanical degradation, ongoing research is focused on mitigating this issue through novel material architectures and binders. Lithium Titanate (LTO) is another anode material known for its exceptional safety and very long cycle life, although it typically has a lower energy density and is used in specific applications like some electric buses.

The Electrolyte: The Ion Highway

While liquid electrolytes currently dominate the landscape of pouch cell batteries, polymer electrolytes are garnering significant attention as promising alternatives, particularly for enhancing safety and enabling innovative battery designs. Polymer electrolytes, as their name suggests, utilize polymers as the ion-conducting medium. These can exist in various forms, including solid polymer electrolytes (SPEs) and gel polymer electrolytes (GPEs).

Solid Polymer Electrolytes (SPEs) consist of lithium salts dissolved in a solid polymer matrix, such as polyethylene oxide (PEO) or polyacrylonitrile (PAN). One of the primary advantages of SPEs is their potential to significantly improve battery safety by eliminating the need for flammable and volatile organic solvents found in traditional liquid electrolytes. This inherent safety feature makes pouch cell batteries employing SPEs attractive for applications where thermal runaway is a major concern. Furthermore, the solid nature of the electrolyte can potentially simplify battery design and enable the creation of thinner and more flexible battery pouch formats.

Gel Polymer Electrolytes (GPEs) represent a hybrid approach, where a polymer matrix is swollen with a liquid electrolyte. This combination aims to leverage the safety benefits of the polymer while maintaining higher ionic conductivity compared to purely solid polymer electrolytes. Common polymers used in GPEs include polymethyl methacrylate (PMMA) and polyvinylidene fluoride (PVDF) copolymers. GPEs are already finding applications in some li ion battery pouch designs, offering an intermediate step towards fully solid-state batteries.

Despite their advantages, polymer electrolytes also face challenges. One of the main limitations is their lower ionic conductivity at room temperature compared to liquid electrolytes, which can impact the power performance of the battery. Extensive research and development efforts are underway to enhance the conductivity of polymer electrolytes through modifications in polymer chemistry, the incorporation of additives, and the development of novel polymer architectures.

The potential benefits of polymer electrolytes, particularly in terms of safety and design flexibility, make them a key area of focus for the future of lithium battery pouch technology. Researchers are actively exploring their use in next-generation batteries for electric vehicles, wearable electronics, and other applications where safety and form factor are critical design considerations. As advancements in materials science continue, polymer electrolytes are expected to play an increasingly significant role in the evolution of pouch lithium ion battery technology.

The Separator: Preventing Short Circuits

A crucial component within every li ion battery pouch is the separator. This thin, porous membrane is positioned between the cathode and anode to prevent direct electrical contact, which could lead to a short circuit and potentially a thermal runaway event. At the same time, the separator must allow for the efficient transport of lithium ions through the electrolyte.

Common separator materials include polyolefins like polyethylene (PE) and polypropylene (PP). These materials offer a good balance of mechanical strength, chemical inertness, and cost-effectiveness. In many advanced pouch lithium ion battery designs, the polyolefin separator is coated with a layer of ceramic material to enhance its thermal stability and prevent the growth of lithium dendrites, which can pierce the separator and cause short circuits. Typical pouch cell separators have a thickness ranging from 20 to 40 micrometers.

Current Collectors and Packaging: Enabling Electron Flow and Protection

To harness the flow of electrons generated by the electrochemical reactions, pouch cell batteries employ current collectors. These are thin metallic foils coated with the electrode materials. Copper foil is typically used for the anode current collector, while aluminum foil is used for the cathode current collector. These materials are chosen for their high electrical conductivity and electrochemical stability within the battery’s operating voltage window.

The outer packaging of a pouch battery cell is a multi-layered laminate, most commonly made of aluminum. This packaging provides a hermetic seal, protecting the internal components from moisture and air, which can degrade battery performance and lifespan. The flexible nature of the aluminum laminate contributes to the lightweight and design versatility of pouch cell batteries, allowing them to be shaped to fit various devices.

Applications of Pouch Cells

The unique characteristics of pouch cell batteries have made them indispensable in a wide range of applications. Their lightweight and flexible design allows them to be integrated into devices with complex shapes and limited space. Some key applications include:

- Consumer Electronics: Smartphones, laptops, tablets, and wearable devices like smartwatches and fitness trackers widely utilize pouch cells due to their slim profile and high energy density.

- Electric Vehicles (EVs): Many modern electric vehicles employ large format pouch cell batteries in their battery packs, offering a good balance of energy density and thermal management capabilities.

- Drones and Robotics: The lightweight nature of pouch battery technology is crucial for maximizing flight time and operational efficiency in drones and robots.

- Medical Devices: Portable medical devices, such as pacemakers and portable oxygen concentrators, rely on the compact and reliable power provided by li ion battery pouches.

- Power Banks and Portable Chargers: The high energy density and lightweight design make lithium battery pouches ideal for portable power solutions.

- Grid Storage: While less common than other formats for large-scale grid storage, pouch lithium ion battery technology is being explored for certain niche applications due to its design flexibility.

Conclusion

The remarkable performance of pouch cell batteries is a testament to the carefully selected and engineered materials that constitute their construction. From the specific lithium-based compounds in the cathode and anode to the ion-conducting electrolyte and the crucial separator, each component plays a vital role in the overall functionality and characteristics of the battery. Ongoing research and development continue to drive innovation in battery materials, promising even higher energy densities, longer lifespans, enhanced safety, and more sustainable solutions for the future of energy storage. For businesses seeking tailored power solutions, Lan Dazzle provides custom lithium battery solutions, leveraging the versatility and performance of pouch cell technology to meet specific application requirements.

FAQ

- What is the main difference in materials between a pouch cell and a cylindrical battery?

- The primary material difference lies in the outer packaging. Pouch cells use a flexible aluminum laminate, while cylindrical batteries are encased in a rigid metal can. This difference impacts the internal design and allows for a higher material utilization in pouch cells.

- Are the materials used in pouch cells environmentally friendly?

- The environmental impact of li ion battery pouch materials is a growing concern. While lithium itself is abundant, the extraction of some materials like cobalt can have environmental and social implications. Recycling efforts are crucial to recover valuable materials and reduce the environmental footprint of lithium battery pouch production.

- How do the materials in a pouch cell affect its lifespan and performance?

- The degradation of materials over time is a key factor limiting battery lifespan. For instance, the formation of a solid electrolyte interphase (SEI) layer on the anode and cathode can impede ion flow. The choice of materials, their purity, and the overall cell design significantly influence performance metrics like energy density, power output, and cycle life of a pouch lithium ion battery.

- What makes pouch cells so lightweight compared to other battery types?

- The flexible aluminum laminate packaging of a pouch battery cell is significantly lighter than the steel casing used in cylindrical or prismatic cells. This contributes to the overall lightweight nature of pouch cell batteries, making them ideal for portable electronic devices and electric vehicles where weight is a critical factor.

- Can the materials in a pouch cell be recycled?

- Yes, the materials in a pouch cell battery, including lithium, cobalt, nickel, manganese, aluminum, and copper, can be recycled. However, the recycling process for lithium-ion batteries is complex and still under development to improve efficiency and cost-effectiveness.

- Are pouch cells made of any hazardous materials?

- Lithium ion battery pouches contain materials that can be hazardous if mishandled or if the battery is damaged. The electrolyte is typically flammable, and the battery contains reactive metals. Therefore, proper handling, storage, and disposal are essential to ensure safety.

- What are some of the latest advancements in materials used for pouch cells?

- Ongoing research is focused on developing new materials to improve the performance, safety, and sustainability of pouch cell batteries. Some key areas of advancement include solid-state electrolytes, high-capacity silicon anodes, advanced cathode materials with higher nickel content or alternative chemistries like lithium-sulfur, and more environmentally friendly binder materials.

source

1. Global Lithium Pouch Cell Market Research Report 2025

2. Progress and perspective of high-voltage lithium cobalt oxide in lithium-ion batteries

3. Performance and Safety of Lithium-Ion Polymer Pouch Cells