Introduction

The performance of any Lipo Battery is highly dependent on its discharge rate. Knowing Lipo Battery Discharge dynamics not only helps in enhancing the battery’s lifespan but also optimizes the performance of high-demand applications—from drones to portable electronics. This article delves into the foundational principles of battery discharge, examines the key factors that influence it, and discusses actionable strategies to optimize battery performance.

Lipo Battery Discharge Basics

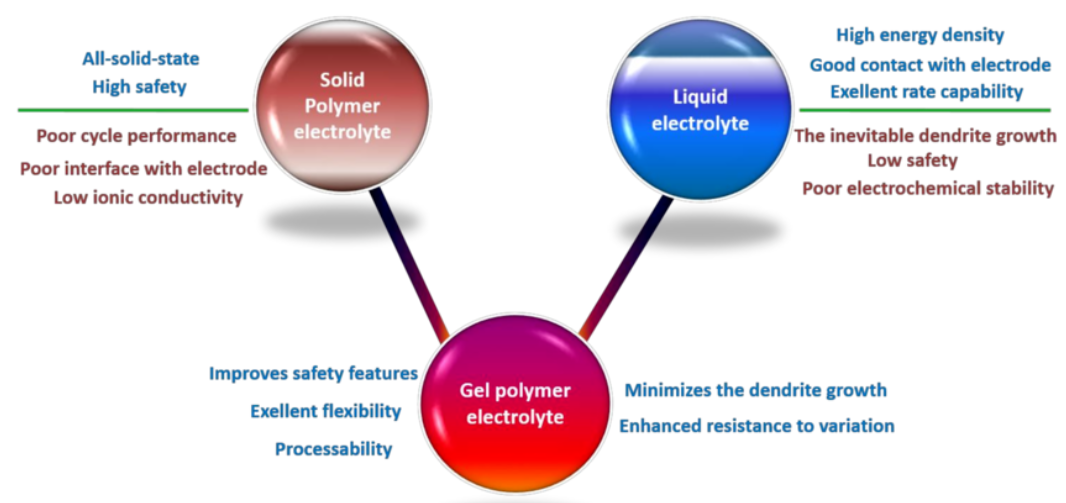

Lithium Polymer batteries are renowned for their lightweight design, high energy density, and flexible form factors, making them ideal for high-performance applications. At the core of a Lipo Battery’s Discharge process is the movement of lithium ions between the anode and cathode through a gel-like polymer electrolyte. This electrochemical reaction converts stored chemical energy into electrical energy, powering devices from drones to portable electronics.

The discharge curve of a LiPo battery typically features a steep voltage drop during the initial phase, followed by a relatively flat plateau, and finally a rapid decline as the battery nears full depletion. This behavior is influenced by internal factors such as electrode composition, electrolyte conductivity, and cell design.

Additionally, the concept of C-rate—which defines the rate at which a battery is discharged relative to its total capacity—is critical to understanding the battery’s performance under different load conditions. For example, a 1C discharge rate means that the battery will discharge its entire capacity in one hour, while a higher C-rate indicates a faster discharge which may lead to increased internal resistance and voltage sag.

Key Factors Influencing Lipo Battery Discharge

A variety of variables can significantly influence the Battery Discharge Rate in LiPo batteries. Understanding these factors helps in predicting performance, prolonging battery life, and ensuring safety:

-

Temperature:

Temperature plays a critical role in the chemical reactions within the battery. High temperatures can accelerate chemical activity, temporarily lowering internal resistance but at the cost of long-term degradation of the electrolyte and electrode materials. Conversely, low temperatures hinder the mobility of lithium ions, resulting in a steeper voltage drop and reduced effective capacity. Maintaining an optimal thermal range is essential to achieving a stable Lipo Battery Discharge. -

Current Draw and Load:

The rate at which a device draws current directly impacts the discharge behavior. High current draws cause rapid energy depletion and can lead to temporary voltage drops—often termed as voltage sag. This is particularly significant in applications with intermittent high-power demands. Designing circuits and devices to manage these load fluctuations is vital for sustaining optimal battery discharge performance. -

Age and Cycle Count:

Over time, repeated charging and discharging cycles contribute to the gradual degradation of battery components. The formation of solid-electrolyte interface (SEI) layers and other chemical changes result in increased internal resistance, directly impacting the efficiency of the discharge process. Monitoring cycle counts and overall battery health is crucial, as aging batteries show a more pronounced drop in performance even under similar load conditions. -

C-rate Rating:

The C-rate is a measure of the discharge current relative to the battery’s capacity. Operating above the specified C-rate stresses the battery, leading to excessive heat generation and potential degradation. Staying within the recommended C-rate is key to preserving the battery’s integrity and ensuring a consistent Lipo Battery Discharge profile. -

Internal Resistance:

Variations in internal resistance, whether from manufacturing differences or aging, can lead to significant energy losses in the form of heat. Higher internal resistance not only diminishes the effective energy output but also accelerates the discharge rate beyond the designed specifications.

How to Discharge a Lipo Battery

Properly discharging a LiPo battery is a critical process that not only ensures the battery’s longevity but also guarantees safety during handling and operation. This section provides a comprehensive guide on how to discharge a LiPo battery safely and effectively.

Preparation and Required Equipment

-

Select the Right Discharge Equipment:

Use a LiPo battery charger/discharger or a dedicated electronic load that supports controlled discharge. These devices are designed to regulate current draw and voltage, ensuring a safe and steady discharge process. -

Set Up a Safe Environment:

Always discharge LiPo batteries in a well-ventilated area, free from flammable materials. Place the battery on a non-conductive surface or within a LiPo-safe bag to mitigate risks in case of accidental short-circuiting. -

Monitoring Tools:

Equip yourself with a reliable multimeter or integrated Battery Management System (BMS) that continuously monitors voltage, current, and temperature throughout the process.

Discharge Procedure

-

Establish a Target Voltage:

LiPo batteries should not be discharged below their recommended minimum voltage, usually around 3.0V per cell (always refer to the manufacturer’s specifications). Setting a target voltage ensures that you avoid over-discharging, which can cause irreversible damage. -

Apply a Constant Load:

Utilize an electronic load or a suitable resistor to apply a steady and controlled load. A constant discharge rate prevents sudden drops in voltage and helps maintain battery health. This controlled method ensures a stable Lipo Battery Discharge profile. -

Monitor Battery Temperature:

Continuously check the battery’s temperature during discharge. If the battery becomes excessively warm, stop the process immediately. Overheating can indicate excessive current draw or potential battery damage.

Safety Precautions

-

Avoid Over-Discharge:

Over-discharging can lead to permanent chemical changes in the battery cells, resulting in reduced capacity or even complete failure. Always adhere to the specified minimum voltage threshold. -

Use a Battery Management System (BMS):

A sophisticated BMS is vital, as it not only oversees voltage and temperature but also helps balance cells, ensuring that no cell falls below safe operating limits. -

Follow Manufacturer Guidelines:

Always consult and adhere to the battery manufacturer’s instructions. This includes specific advice on discharge rates, load requirements, and safe handling practices to prevent any operational hazards.

Post-Discharge Handling

-

Immediate Recharge:

Once the discharge is complete, recharge the battery promptly using a charger that is compatible with LiPo technology. Avoid leaving the battery at low voltage for extended periods, as this can compromise its lifespan. -

Safe Storage:

After recharging, store the battery in a cool, dry location. For enhanced safety, use a LiPo-safe storage bag or container to protect against potential risks and environmental damage.

Conclusion

Understanding and controlling the factors that influence Lipo Battery Discharge is essential for any technology relying on Lithium Polymer Batteries. By addressing temperature effects, managing load and current draw, monitoring battery age and internal resistance, and implementing a robust battery management system, manufacturers can dramatically improve battery performance and safety. These strategies not only optimize battery life but also contribute to more reliable and efficient products. As technology evolves, continuous research and adaptation of best practices will remain key to achieving optimal Lipo Battery Efficiency.

FAQs

-

What are the primary safety measures to prevent LiPo battery fires?

Ensure proper storage, avoid overcharging, and always use chargers designed for LiPo batteries. Additionally, regularly inspect batteries for physical damage and swelling. -

How can I determine when my LiPo battery needs to be replaced?

Monitor changes in performance, such as reduced capacity and irregular voltage drops, and use a battery management system to flag significant degradation. -

Do LiPo batteries require a specific charging method to maintain optimal discharge performance?

Yes, using a charger that matches the battery’s specifications and supports balanced charging is crucial to avoid overcharging and maintain consistent performance. -

What certifications or standards should I look for when purchasing LiPo batteries?

Look for certifications like UL, CE, or IEC, which indicate compliance with international safety and performance standards. -

How do LiPo batteries compare to other battery types in terms of discharge performance and efficiency?

LiPo batteries typically offer higher energy density and faster discharge rates than many traditional batteries, making them ideal for high-demand applications where weight and size are critical.