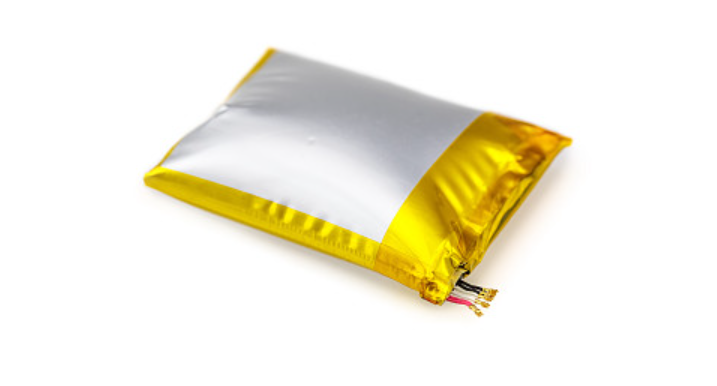

An ultra-thin battery is a cutting-edge power source designed to be as thin as possible while maintaining efficiency, safety, and long-lasting performance. These batteries are revolutionizing industries by enabling the development of increasingly compact and versatile devices. Ultra-thin batteries are particularly suited for applications where space is at a premium, such as in wearable electronics, medical devices, and advanced consumer products.

Introduction to Ultra-Thin Batteries

Ultra-thin batteries are typically made using lithium-ion or lithium-polymer technologies. These batteries are designed with minimal thickness, which allows them to fit into ultra-compact devices while still providing sufficient power. Ultra-thin batteries are also highly customizable, making them an ideal choice for industries that require unique shapes or sizes for specific applications.

Technical Requirements for Manufacturing Ultra-Thin Batteries

The manufacturing of ultra-thin batteries involves sophisticated engineering and design processes that must meet specific technical requirements to ensure high performance, safety, and durability. As the demand for smaller, more efficient power sources grows, these technical challenges are becoming increasingly important. Below, we dive deeper into the essential factors that influence the production of ultra-thin batteries.

1. Material Selection

Material selection is one of the most critical aspects when manufacturing ultra-thin batteries. The materials chosen must not only be lightweight and thin but also capable of maintaining high energy density and power output.

-

Electrode Materials: The electrodes in ultra-thin batteries need to have high conductivity and stability. Materials such as graphene, silicon, and lithium cobalt oxide (LiCoO2) are commonly used for ultra-thin electrodes. Graphene, in particular, has become a material of interest due to its high electrical conductivity and flexibility. Silicon, with its ability to store more lithium ions than conventional carbon-based anodes, is also widely researched for enhancing energy capacity while keeping the overall thickness low.

-

Electrolyte Materials: In ultra-thin batteries, solid-state electrolytes, such as sulfide-based and oxide-based solid electrolytes, are becoming more common because they can offer better stability and safety compared to liquid electrolytes. Liquid electrolytes, while still used, pose challenges in ultra-thin batteries due to leakage risks in thin packaging.

-

Separator Materials: Separators in ultra-thin batteries must be incredibly thin while still preventing short circuits between the anode and cathode. Advanced polymer and ceramic materials are often used because of their durability and insulating properties. These materials must be both thin and resilient to mechanical stress, ensuring long-term battery reliability.

2. Battery Capacity and Energy Density

One of the primary technical challenges in ultra-thin battery manufacturing is achieving a balance between capacity and energy density while keeping the battery thin. The goal is to create a power source that is small enough to fit into compact devices but still provides sufficient energy to power them for a reasonable period.

-

Energy Density: Ultra-thin batteries often need to maximize energy density (measured in Wh/kg or Wh/L) without increasing thickness. Advances in high-energy-density cathodes and high-capacity anodes are crucial in meeting these demands. For instance, combining lithium cobalt oxide with graphene can significantly increase the energy density while keeping the battery thin.

-

Capacity: The capacity of an ultra-thin battery is directly tied to its energy density. A key factor is the choice of electrode material, as mentioned earlier. Using a combination of nanoscale electrode structures allows for more efficient packing of energy, which can improve battery capacity without sacrificing its thin form factor.

3. Flexible Design and Mechanical Stress Resistance

Ultra-thin batteries are often required to be flexible, which introduces unique challenges in their design and manufacture. These batteries are used in applications like wearable devices and flexible electronics, where they need to bend and conform to the shape of the device without damaging the internal components.

-

Flexible Substrates: The battery’s substrate, typically the current collector, needs to be flexible while maintaining electrical conductivity. Materials such as stainless steel, copper foil, and polymer-based substrates are used to create these flexible foundations.

-

Thin-Film Electrodes: To achieve the necessary flexibility, ultra-thin batteries rely on thin-film electrodes. These are typically manufactured using processes like pulsed laser deposition (PLD), sputtering, or electroplating to create extremely thin yet effective layers of active materials.

-

Bendable Components: The battery’s components, including the anode, cathode, and electrolyte, must be designed in such a way that they can withstand mechanical stress and deformation without losing their functionality. Thin layers of polymers or ceramic materials are often used to ensure that the components retain their integrity under bending or flexing.

4. Safety and Reliability

Safety is a paramount concern in all battery manufacturing processes, but it is even more critical for ultra-thin batteries due to their delicate nature. Ultra-thin batteries are more susceptible to damage, such as punctures, deformation, or short-circuiting, which could lead to overheating or even fires.

-

Safety Features: Manufacturers of ultra-thin batteries must implement various protective layers and fail-safe mechanisms. These may include thermal shut-down separators, pressure-sensitive layers, and overcharge protection circuits. For ultra-thin batteries, multi-layer protection films are crucial to prevent internal short circuits or leaks.

-

Encapsulation: A robust encapsulation is required to protect the internal components from external mechanical damage. Thin, flexible encapsulation materials such as epoxy resins or polymer films help ensure that the battery is resistant to punctures or bending beyond its threshold.

-

Thermal Management: As ultra-thin batteries generate heat during charge and discharge cycles, efficient thermal management is critical. Thin-film heat dissipation techniques, such as integrating heat-dissipating materials or using conductive polymer films, are employed to maintain safe temperature levels and prevent overheating.

5. Precision Manufacturing and Quality Control

Due to the ultra-thin nature of these batteries, manufacturing precision is essential. Even the smallest imperfection in the battery structure can lead to failure or reduced performance. Advanced manufacturing techniques are used to ensure high precision and quality in ultra-thin battery production.

-

Automated Manufacturing Processes: Ultra-thin batteries are produced through automated processes that use precision machinery for tasks like cutting, layering, and coating. These processes must be carefully controlled to avoid introducing defects, such as air bubbles or uneven coatings.

-

Testing and Quality Assurance: Every batch of ultra-thin batteries undergoes rigorous testing for electrical performance, mechanical stress resistance, and safety. This involves testing for factors like charge-discharge cycles, voltage stability, and the ability to maintain performance after exposure to various environmental conditions.

Characteristics of Ultra-Thin Batteries

Ultra-thin batteries have several key characteristics that distinguish them from traditional power sources:

- Compact Size: These batteries are extremely small and lightweight, making them ideal for applications where space and weight are critical.

- Flexibility: Many ultra-thin batteries are also flexible, allowing them to conform to various shapes and sizes.

- High Energy Density: Despite their small size, ultra-thin batteries are designed to provide a relatively high energy output, ensuring devices remain powered for extended periods.

- Customizability: Ultra-thin batteries can be tailored to fit the specific requirements of different industries, from medical implants to wearable technology.

- Environmental Friendliness: Some ultra-thin batteries are designed with eco-friendly materials, contributing to sustainability efforts.

Applications of Ultra-Thin Batteries

The ultra-thin battery technology has opened up new possibilities in various fields. Some of the key applications include:

-

Wearable Electronics: Ultra-thin batteries are used in smartwatches, fitness trackers, and other wearable devices. These batteries provide power without adding bulk, ensuring a comfortable user experience.

-

Medical Devices: For medical applications, such as implantable devices and smart prosthetics, ultra-thin batteries are essential to provide long-lasting power while maintaining the smallest possible size.

-

Consumer Electronics: Ultra-thin batteries power devices like smartphones, tablets, and other compact gadgets. As these devices become smaller and more portable, the demand for ultra-thin, high-performance batteries increases.

-

IoT Devices: Ultra-thin batteries are used in Internet of Things (IoT) devices, such as sensors and smart home products, where compactness and longevity are key factors.

-

Flexible Displays: In combination with flexible electronics, ultra-thin batteries are crucial for powering flexible displays and other innovative products that require bending and shaping without compromising functionality.

Lan Dazzle’s Ultra-Thin Battery Solutions

At Lan Dazzle, we specialize in providing customized ultra-thin battery solutions for a variety of applications. Our batteries are designed with advanced technologies to ensure maximum performance in the most compact forms. Whether for wearable electronics, medical devices, or flexible displays, our ultra-thin batteries are engineered to meet the specific needs of our clients.

We focus on offering high energy density, flexibility, and safety in every battery we produce. With our expertise in custom lithium polymer batteries and other specialized solutions, Landazzle provides cutting-edge products that help businesses achieve their innovation goals.

FAQs about Ultra-Thin Batteries

1. What are the main advantages of ultra-thin batteries?

Ultra-thin batteries offer advantages such as compact size, flexibility, high energy density, and the ability to be customized to fit unique design requirements.

2. Can ultra-thin batteries be used in flexible devices?

Yes, ultra-thin batteries are often designed to be flexible, making them ideal for use in flexible electronics, wearable technology, and other devices that require bendable power sources.

3. How safe are ultra-thin batteries?

Although ultra-thin batteries are more delicate than traditional batteries, advanced engineering techniques such as multi-layer insulation and reliable encapsulation ensure they are safe and reliable for use.

4. What materials are used in ultra-thin batteries?

Materials commonly used in ultra-thin batteries include lithium-ion and lithium-polymer technologies, as well as advanced materials such as solid-state electrolytes and graphene-based components.

5. What industries use ultra-thin batteries?

Industries such as wearable electronics, medical devices, IoT applications, consumer electronics, and flexible displays all utilize ultra-thin batteries due to their compact and versatile nature.