Table of Contents

In the evolving world of lithium-ion battery manufacturing, the internal assembly method has become a vital differentiator—especially when it comes to pouch cell battery for custom-shaped devices. As custom shaped battery manufacturer, we have seen first-hand how the choice between the stacking process and the traditional winding process can lead to significant differences in performance, reliability and manufacturability.

In this article, we will dig deep into why stacking beats winding for pouch cell battery applications—covering energy density, internal structure stability, thermal management, safety, and how these advantages translate into custom-battery success.

What is a Pouch Battery?

A pouch cell battery is a lithium-ion cell format that uses a flexible laminated aluminium-polymer film instead of a rigid metal can. It offers high packaging efficiency (90-95 %) and flexible form factors. Pouch cells are increasingly used in robotics, drones, custom wearables, and e-mobility platforms thanks to their lightweight, adaptable shape and high performance.

What is Stacking Process?

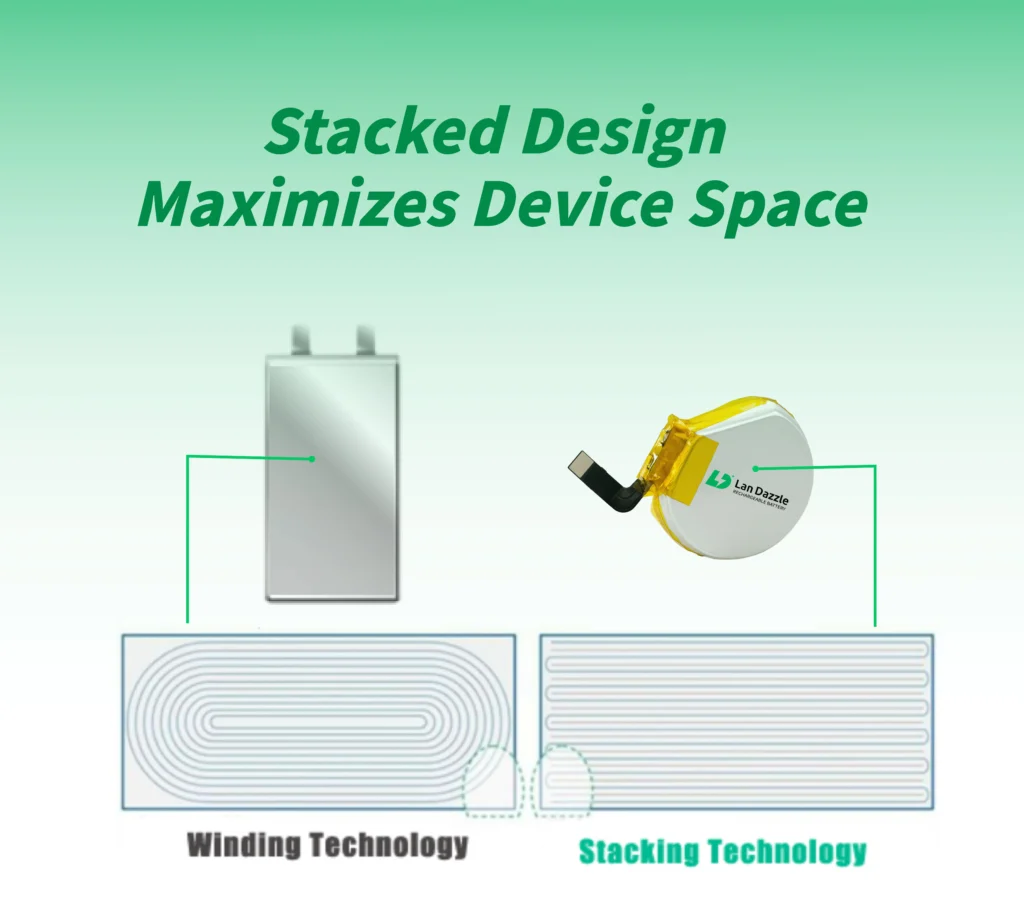

The stacking process — also known as lamination or Z-stacking — is a cell assembly method used in lithium-ion battery manufacturing, especially for pouch cells and prismatic cells.

Instead of rolling the electrode sheets into a spiral (as in the winding process), stacking cuts and layers the electrodes and separators into a flat, multi-layered structure.

What is Winding Process?

The winding process is one of the most traditional and widely used methods for assembling lithium-ion battery cells. In this process, the electrode sheets — a long strip of anode, separator, and cathode — are wound together into a tight spiral or roll, often called a “jelly roll” structure. This technique is commonly used for cylindrical cells (like 18650 or 21700), but it’s also applied in some prismatic and pouch cells where high-volume, low-cost production is required.

Features of the Stacking Process vs Winding Process

| Feature | Stacking Process | Winding Process |

|---|---|---|

| Structure Type | Flat, layered stack of electrodes and separators | Spiral roll of continuous electrodes and separators |

| Shape Compatibility | Excellent — supports flat, thin, curved, or custom shapes | Limited — mainly suited for cylindrical or rectangular cells |

| Energy Density | Higher (no empty corners, better material use) | Slightly lower due to curved edges and winding gaps |

| Electrode Alignment | Precisely aligned layers; uniform thickness | Uneven inner/outer stress and coating deformation risk |

| Thermal Management | Superior — heat spreads evenly across flat layers | Moderate — inner layers may trap more heat |

| Electrical Resistance | Lower — multiple parallel tabs and short current paths | Higher — longer current paths in spiral form |

| Mechanical Stress During Cycling | Uniform expansion and contraction; longer cycle life | Uneven stress distribution; potential for deformation |

| Safety & Reliability | High — less risk of burrs, deformation, or short circuits | Moderate — bending points can damage separator coatings |

| Manufacturing Complexity | Higher — requires precise cutting and stacking machines | Lower — simpler and faster process for mass production |

| Production Speed & Cost | Slower and costlier; ideal for high-performance cells | Faster and cheaper; ideal for high-volume production |

| Customization Flexibility | Excellent — ideal for irregular or thin pouch designs | Limited — constrained by roll geometry |

| Applications | High-end pouch or prismatic cells (drones, robotics, wearables) | Cylindrical cells (18650, 21700), EVs, e-bikes, power tools |

Why Stacking Beats Winding for Pouch Battery?

Higher Energy Density & Better Space Utilisation

The flat geometry of a stacked core allows for more efficient use of the internal space of the pouch format. Winding leaves curved edges and unused volume at the roll’s corners, reducing volumetric capacity.

Enhanced Internal Structure Stability

In a wound cell, the inner layers and outer layers of the roll undergo different expansion and contraction during charge–discharge cycles. This non-uniform stress can lead to deformation, interface degradation and reduced life. By contrast, stacked cells have more uniform layer geometry, resulting in better thickness control, less bulging and improved cycle life.

Superior Thermal & Electrical Performance

Stacked cells permit multiple tabs (connections) in parallel, reducing internal resistance and heat generation. Also, thermal management is easier in flat-stacked formats, heat is more evenly distributed and the risk of hot spots is reduced compared to wound cores with curved geometry.

Safety Benefits & Long-Term Reliability

The absence of tight bends and wrap corners in stacked cells reduces the risk of coating deformation, separator damage, burr formation and subsequent internal short-circuits. For applications requiring extended life-cycles (robotics, drones, industrial) and stringent safety requirements, these structural advantages matter.

Considerations & Trade-Offs in Manufacturing

While stacking offers many performance benefits, the process has its own challenges.

Manufacturing Complexity & Yield

Stacking involves precise cutting, alignment, multi-layer stacking and often more tab welding than simple winding. These add process complexity, cost and can reduce yield. In contrast, winding is mature, efficient and lower-cost for standard formats.

Production Efficiency & Cost

Because the stacking machines are more complex and slower, unit throughput may be lower and equipment cost higher. This means stacking is often favoured when performance or form-factor demands justify it.

Suitability for Custom or Unique Form Factors

Stacking gives much greater flexibility in electrode shape and cell geometry, making it ideal for custom pouch cell battery designs — thin, curved, or irregular shapes required by robots, drones or aerospace components. Winding is more constrained by its roll geometry.

Why LanDazzle Chooses Stacking for Custom Pouch Cell Solutions

LanDazzle specializes in custom pouch cell battery manufacturing (including curved pouch, high-energy density, and low-temperature variants) for applications in medical devices and wearables. The decision to adopt stacking technology aligns with our commitment to performance, flexibility and quality.

- Higher volumetric energy density: By using stacking, we maximise active material loading in custom pouches, enabling longer run times in compact volumes.

- Design flexibility: Our stacking process supports bespoke shapes and sizes—whether a thin curved battery for a wearable or a compact module for an agricultural drone.

- Enhanced reliability: Flat stacked cores mean fewer stress points, fewer chances of internal deformation—critical for high-cycle, high-reliability devices.

- Tailored manufacturing: While stacking requires more sophisticated equipment and process control, our facility is fully equipped for these demands, making us a leader in custom solutions.

Conclusion

In summary, when designing a pouch cell battery for custom, high-performance applications—especially where form-factor, run-time, reliability or thermal/structural performance matter—the stacking process beats the traditional winding method. With higher energy density, better internal consistency, superior thermal and electrical performance and greater shape flexibility, stacked pouch cells offer compelling advantages.

At LanDazzle, our customised stacking-based pouch cell battery solutions empower engineers and product designers to turn demanding specifications into reality. If you’re looking for a trusted lithium-ion battery partner who delivers bespoke pouch cell solutions built on stacking technology—get in touch with us today to discover how we can help your device outperform.

Contact LanDazzle today to discuss your custom pouch battery needs and discover how our solutions can enhance your product.

Email: info@landazzle.com

Whatsapp: +8618938252128