The rise of augmented reality (AR) and mixed-reality technologies has paved the way for smart glasses to evolve from a niche product to a mainstream device, increasingly adopted across various industries, from healthcare to field services. However, one of the most significant hurdles faced by engineers working on these devices is finding a reliable, slim, and high-performance battery solution. This is where custom flexible lithium polymer (LiPo) batteries come into play.

In this article, we’ll explore how custom flexible LiPo batteries are transforming the smart glasses market, the key technical requirements for these batteries, the manufacturing process, and the benefits of working with a trusted LiPo battery manufacturer to meet your specific design needs.

Market Trends & Opportunity

The global smart glasses market is booming, driven by the rapid adoption of AR technology. The smart glasses battery market is expected to be worth $2 billion by 2025, with a 25% compound annual growth rate (CAGR) through 2033. This growth is attributed to the increasing use of smart glasses in sectors such as healthcare, military, manufacturing, and logistics, where AR offers significant productivity enhancements.

As demand for smart glasses continues to rise, the need for high-performance batteries has never been greater. A crucial segment within this market is flexible batteries, which are essential for wearable devices like smart glasses. Flexible LiPo batteries, specifically, are expected to grow at a 26.6% CAGR from 2024 to 2030. This growth is due to the need for ultra-thin, flexible, and reliable power sources in wearables, where traditional rigid batteries simply won’t fit.

For R&D engineers developing next-generation smart glasses, these trends present both challenges and opportunities. The need for slim and efficient battery solutions is paramount, and flexible LiPo batteries offer the perfect solution.

Technical Requirements for Smart Glasses Batteries

Smart glasses require batteries that can meet the unique challenges posed by their compact form factor and the demands of AR applications. Below are the key technical requirements for smart glasses batteries:

Energy Density & Form Factor

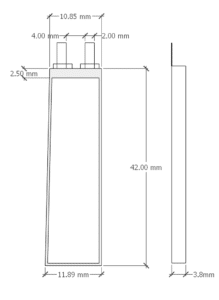

To power smart glasses for an extended period without adding bulk, batteries must offer high energy density. Ideally, the battery should provide at least 200 Wh/kg while maintaining a slim profile, typically under 3 mm in thickness. Custom micro-cells—with capacities ranging from 100 mAh to 200 mAh—are often used to power these devices.

The form factor is equally crucial. Unlike traditional batteries that come in standard shapes, smart glasses require custom-designed batteries that can fit snugly into curved frames or smaller components like the temples or the bridge. A flexible LiPo battery allows for such designs, making it possible to provide power without sacrificing comfort.

Operating Temperature & Reliability

Smart glasses are intended for use in diverse environments, ranging from indoor office settings to outdoor industrial applications. As such, batteries must operate efficiently across a wide temperature range, typically –20°C to +60°C. Ensuring that the battery can withstand extreme temperatures without affecting its performance or safety is essential.

In addition, these batteries must maintain reliability over time. A smart glasses battery should last at least 500 charge cycles and retain 80% of its original capacity after these cycles. This ensures that the device remains functional for years without the need for frequent battery replacements.

Safety & Lifecycle

Safety is another critical factor in designing batteries for wearable devices. Smart glasses batteries must adhere to strict safety standards such as IEC 62133 and UL 2054. Features like Positive Temperature Coefficient (PTC) devices, Current Interrupt Devices (CID), and flame-retardant separators are essential for ensuring safety during normal operation and under abuse conditions.

Flexible LiPo batteries are particularly prone to swelling due to their construction, so it is crucial to ensure that these batteries can withstand mechanical stress while maintaining safe operation.

Flexible LiPo Battery Technology

Flexible LiPo batteries are the ideal power source for smart glasses due to their ability to fit into slim, compact spaces and provide high energy density. Below, we explain the core technologies behind flexible LiPo batteries:

Materials & Electrodes

Flexible LiPo batteries use silicon-composite anodes to enhance capacity. Silicon is known for its higher theoretical capacity compared to traditional graphite anodes, but it faces challenges like volume expansion. To mitigate this, composite anodes that combine silicon with carbon-based materials are used to maintain stability.

On the cathode side, Nickel Manganese Cobalt (NMC) materials are commonly used. This cathode chemistry offers a good balance between energy density, safety, and cycle life.

Thin-Film Techniques

The construction of flexible LiPo batteries requires advanced manufacturing techniques like vacuum deposition and roll-to-roll printing. These methods allow for the creation of thin films that can be rolled or bent without compromising performance, making them perfect for applications like smart glasses, which require batteries that can conform to curved surfaces.

Pouch Cell Construction

Flexible LiPo batteries are often designed as pouch cells. Unlike rigid cells that use metal casings, pouch cells are made with thin, flexible aluminum laminates. This allows them to bend and fit into unconventional shapes, which is critical for wearables. The edge seals of pouch cells are critical and are typically created using high-precision laser welding to prevent electrolyte leakage during bending.

Performance Metrics

Flexible LiPo batteries can achieve C-rates of up to 3 C, which means they can discharge at three times their rated capacity. This high discharge rate is necessary for the short bursts of power that smart glasses require for tasks like high-brightness displays or processing-intensive AR applications. These batteries typically offer 300–500 cycles, ensuring longevity without significant degradation.

Custom Manufacturing Process

Creating a custom flexible LiPo battery for smart glasses involves several critical steps:

Design Brief & Prototyping

The first step in the custom battery manufacturing process is the design brief. R&D engineers collaborate with battery manufacturers to create a detailed specification of the battery, including its dimensions, capacity, and any special requirements. Prototyping is then carried out using 3D-printed molds, allowing manufacturers to test the fit and performance of the battery in real-world conditions.

Electrode Fabrication

Once the design is finalized, the electrodes are fabricated. This process involves mixing electrode slurry, coating it onto a substrate, and controlling the thickness to ensure the desired energy density. Precise coating techniques, such as doctor-blade coating, are used to achieve the necessary uniformity.

Cell Assembly & Sealing

The electrodes and separator are assembled in a dry room with low humidity (<1% RH) to prevent moisture from affecting the battery’s performance. The cells are then laminated, vacuum dried, and filled with electrolyte. The final step involves laser welding the pouch seals to create an airtight barrier that prevents electrolyte leakage.

Testing & Validation

Before the battery is integrated into a smart glasses design, it undergoes rigorous testing. Accelerated life tests simulate years of use by subjecting the battery to high temperatures and cycles of charge and discharge. Thermal cycling tests ensure that the battery can perform reliably under extreme temperature fluctuations. Additionally, safety tests such as overcharge, short-circuit, and nail penetration tests are conducted to meet UL 2054 and IEC 62133 standards.

Quality Assurance & Compliance

Ensuring the quality and safety of flexible LiPo batteries for smart glasses requires adherence to strict standards. The primary safety certifications for these batteries are IEC 62133 and UL 2054, which specify the safety requirements for portable and household lithium batteries.

Testing protocols include overcharge/over-discharge tests, which ensure that the battery does not overheat or degrade under excessive charge or discharge conditions. Thermal abuse tests simulate exposure to high temperatures to confirm that the battery does not enter thermal runaway.

Additionally, traceability is crucial in the manufacturing process. Each battery is assigned a lot code that tracks its components, ensuring that any issues can be quickly identified and addressed.

LanDazzle: Smart Glasses Battery Manufacturer

At Lan Dazzle, we specialize in designing and manufacturing high-quality smart glasses battery. Our trapezoid battery batteries are engineered to meet the specific needs of compact devices like smart glasses and other portable electronics. We ensure that our batteries deliver reliable power, long-lasting performance, and safety in the smallest form factors.

With years of experience in battery manufacturing, Lan Dazzle offers customized battery solutions for a wide range of applications. Whether you’re developing a new smart card or upgrading existing technology, we provide the perfect battery solutions for your products.

You can get the following services from Lan Dazzle:

●Flexible support for customized solutions

●Reliable and stable performance

●Samples and mass production available

●OEM, ODM services available

FAQ Section

1. What capacity do smart glasses batteries typically require?

Smart glasses typically require batteries with capacities ranging from 100 mAh to 200 mAh, depending on the desired runtime and form factor.

2. How do flexible LiPo batteries improve wearer comfort?

Flexible LiPo batteries can conform to the slim, curved shape of smart glasses, making them more comfortable for long-term wear without compromising on power.

3. Which safety certifications should I look for?

Look for batteries that comply with IEC 62133 and UL 2054 for safety standards, ensuring reliable performance and safety in wearable applications.

4. Can custom LiPo packs support wireless charging (Qi)?

Yes, custom LiPo packs can be designed to support wireless charging by incorporating appropriate coils and charging circuits.

5. How many cycles can I expect from a flexible pouch cell?

Flexible pouch cells typically offer between 500 to 1000 cycles while retaining 80% of their original capacity.

6. What factors influence the cost of bespoke micro-batteries?

The cost of custom micro-batteries is influenced by factors such as cell capacity, cycle life requirements, complexity of design, and certification needs.

Conclusion

Custom flexible LiPo batteries are essential for powering the next generation of smart glasses. By offering high energy density, slim form factors, and excellent performance in diverse conditions, these batteries ensure that smart glasses can deliver the best user experience without compromising on design. Working with a trusted manufacturer can help you bring your innovative smart glasses vision to life. Contact us today at info@landazzle.com to discuss how our custom flexible LiPo battery solutions can meet your specific needs.