Table of Contents

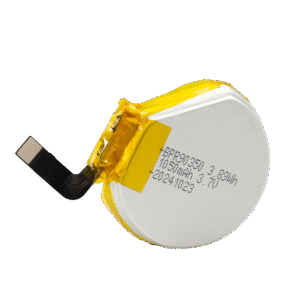

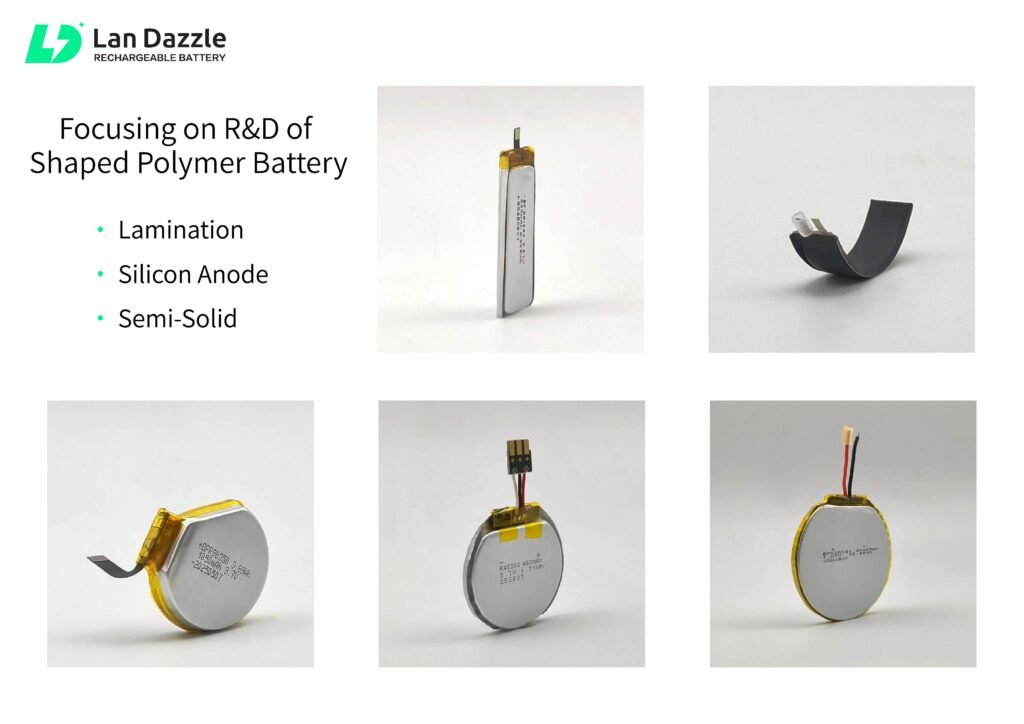

A lithium polymer battery cell is a type of rechargeable lithium-ion battery that uses a polymer-based electrolyte instead of liquid. This design makes LiPo cells lighter, thinner, and more flexible, allowing for custom shapes and sizes to fit modern electronic devices.

LiPo cells are ideal for applications where space, weight, and design flexibility matter, including consumer electronics like smartwatches and tablets, as well as drones, robotics, and medical devices. Their high energy density and reliable power output make them suitable for both compact and high-performance devices.

What the “Polymer” Means?

The term “polymer” in a lithium polymer battery cell refers to the solid or gel-like polymer electrolyte used instead of the liquid electrolyte found in conventional lithium-ion cells. This polymer electrolyte allows the battery to maintain flexibility and a lightweight, thin form factor, enabling custom shapes that suit modern device designs.

Compared to traditional liquid electrolytes, the polymer structure also enhances safety by reducing the risk of leakage and offering better mechanical stability. Additionally, it can influence performance characteristics such as internal resistance, charge/discharge efficiency, and thermal behavior, making LiPo cells particularly well-suited for compact, high-performance applications.

Key Components of a LiPo Cell

A lithium polymer battery cell is composed of several essential components that work together to store and deliver electrical energy efficiently:

- Cathode (Positive Electrode) – The cathode is typically made of a lithium metal oxide and serves as the source of lithium ions during discharge. It determines the battery’s capacity and voltage.

- Anode (Negative Electrode) – Usually made of graphite or other carbon-based materials, the anode stores lithium ions during charging and releases them during discharge. It plays a key role in energy density and cycle life.

- Separator – This thin, porous layer keeps the anode and cathode physically apart while allowing ions to pass through. It is crucial for preventing short circuits and maintaining safe operation.

- Electrolyte – In LiPo cells, the electrolyte is a solid or gel polymer that conducts lithium ions between the electrodes. It contributes to the battery’s flexibility, stability, and safety.

- Flexible Aluminum-Laminated Pouch – The soft, lightweight casing protects internal components while allowing custom shapes and sizes. It also enhances thermal management and reduces overall battery weight compared to rigid metal casings.

LiPo vs Li‑Ion – Key Differences

While both lithium polymer and lithium-ion batteries share the same basic electrochemical principles, their design and performance characteristics differ significantly:

- Casing – LiPo cells use a flexible, lightweight aluminum-laminated pouch, whereas Li‑Ion cells typically have a rigid metal casing. This makes LiPo cells more adaptable to custom shapes and thinner designs.

- Energy Density and Weight – LiPo batteries generally offer comparable energy density to Li‑Ion cells but are lighter, which is advantageous for drones, wearables, and other portable devices.

- Form Factor Flexibility – LiPo’s soft pouch allows for custom shapes and sizes, while Li‑Ion cells are usually limited to cylindrical or prismatic forms.

- Safety and Swelling – LiPo cells are more prone to swelling under improper charge or temperature conditions but reduce leakage risks due to their polymer electrolyte. Li‑Ion cells are mechanically more robust but heavier.

- Typical Applications – LiPo cells excel in drones, robotics, wearables, and compact electronics, where weight and flexibility are critical. Li‑Ion cells are often preferred for power banks, electric vehicles, and larger energy storage systems, where structural rigidity and slightly higher energy density per volume are advantageous.

What Are the Advantages of Lipo Cell?

High Energy Density – LiPo cells can store a large amount of energy relative to their size, enabling longer operation times in compact devices.

Custom Shapes and Curved Designs – The flexible pouch allows for curved or uniquely shaped batteries, providing design freedom for innovative device form factors. This makes curved LiPo batteries particularly useful in wearables, VR headsets, and other space-constrained applications.

Lightweight and Compact – LiPo cells are significantly lighter than traditional rigid batteries, making them perfect for portable electronics, drones, and micro-devices where weight reduction is critical.

High Discharge Rate – LiPo batteries can deliver high current output, which is essential for devices like drones, robotics, and electric tools that require bursts of power. These high-discharge LiPo batteries ensure reliable performance under demanding conditions.

Safety and Low Internal Resistance – The polymer electrolyte reduces leakage risk, while low internal resistance enhances efficiency and thermal stability, improving both performance and safety.

What Are the Disadvantages of Lipo Cell?

While lipo batteries offer many advantages, there are several limitations and considerations to keep in mind:

- Higher Cost – Compared to traditional lithium-ion batteries, LiPo cells are generally more expensive due to their flexible packaging and manufacturing complexity.

- Limited Cycle Life – LiPo batteries typically have a shorter lifespan than some rigid Li-ion cells, and performance can degrade faster under frequent high-current discharge.

- Swelling and Puffing Risk – Improper charging, over-discharge, or exposure to high temperatures can cause the battery to swell or puff, which may compromise safety and device fit.

- Temperature Sensitivity – LiPo cells are sensitive to extreme temperatures, both hot and cold, which can affect capacity, performance, and safety.

- Battery Management System (BMS) Requirement – Proper BMS or protection circuitry is essential to prevent overcharge, over-discharge, and short circuits.

- Storage and Transportation – Special care is required during storage and shipping to avoid mechanical damage, temperature extremes, and potential hazards.

What Are the Applications of Lithium Polymer Battery?

Consumer Electronics

LiPo cells are commonly found in smartwatches, wireless earbuds, tablets, and VR devices, where compact size and lightweight design are essential. Their high energy density ensures longer operating times in small devices without adding bulk.

Drones & UAVs

For drones and UAVs, LiPo batteries provide the high current output required for motors and flight control systems while keeping the overall weight low. This combination of power and lightness enables longer flight times and better maneuverability.

Robotics & Tools

LiPo cells are ideal for electric tools, educational robots, and industrial robotics, offering high discharge rates to drive motors efficiently. Their customizable shapes allow integration into compact or uniquely designed devices.

Wearables & Medical Devices

Wearables such as fitness trackers and heart rate monitors, as well as portable medical devices, benefit from LiPo batteries’ thin and flexible form factor. This enables comfortable, unobtrusive designs while maintaining reliable power delivery.

Low-Temperature / Harsh Environment Applications

Specialized LiPo cells are designed for low-temperature operation, making them suitable for cold-weather drones, electric tools, and e-bikes. These low temperature LiPo batteries ensure consistent performance in extreme conditions, while other batteries for cold weather often struggle with reduced capacity and efficiency.

How to Choose or Customize a LiPo Battery?

Selecting the right polymer battery requires careful consideration of several key factors to ensure optimal performance, safety, and compatibility with your device.

Voltage, Capacity, and Sizing Considerations

Start by calculating your device’s power requirements and determining the appropriate voltage and capacity. Proper matching ensures that the battery can deliver sufficient energy without overloading or underperforming. Physical size and thickness should also be considered to fit the battery seamlessly into the device’s design.

Discharge Rate (C-Rate) and Current Requirements

High-power devices such as drones, electric tools, or robotics require batteries with a high discharge rate (C-rate) to deliver bursts of current safely and efficiently. Selecting the right C-rate ensures consistent performance under heavy load and prevents overheating or premature wear.

Shape/Form Factor & Mechanical Constraints

The flexible nature of LiPo cells allows for curved, thin, or custom-shaped designs. Carefully assessing the device’s available space and mechanical constraints helps optimize battery placement while maintaining the device’s structural integrity and aesthetics.

Safety, Thermal Management, Cycle Life

Incorporate a Battery Management System (BMS) to protect against overcharge, over-discharge, and short circuits. Proper thermal management ensures stable operation and longevity, while attention to cycle life allows the battery to meet expected usage demands over time.

Certifications and Regulatory Considerations

Ensure the battery complies with international safety and quality standards, such as CE, UN38.3, and IEC certifications, especially if the device will be sold commercially or transported globally. Compliance guarantees safe operation, legal distribution, and customer confidence.

Future Trends in LiPo Technology

The field of lipo batteries is evolving rapidly, driven by the demand for higher performance, lighter weight, and flexible energy solutions. Key trends include:

- Solid-State Polymer Batteries – These batteries replace traditional liquid or gel electrolytes with a solid polymer, offering enhanced safety, higher energy density, and longer cycle life.

- High-Energy-Density and High-Voltage LiPo – Designed to provide more power without increasing size or weight, ideal for drones, electric vehicles, and high-performance robotics.

- Ultra-Thin and Flexible Batteries – Enabling curved wearables, foldable electronics, and other devices where space and shape flexibility are critical.

- Sustainability and Recycling – Eco-friendly materials and battery recycling are becoming integral to future LiPo technology, reducing environmental impact.

- Drones and Aerospace Applications – These fields drive innovation, requiring lightweight, high-capacity batteries capable of reliable operation in extreme environments.

These trends indicate that LiPo batteries will remain central to the next generation of portable and high-performance devices, combining efficiency, safety, and design flexibility across diverse applications.

Conclusion

Lithium polymer battery cells offer a unique combination of high energy density, lightweight design, and flexibility, making them ideal for a wide range of applications—from consumer electronics and wearables to drones, robotics, and medical devices. While they come with considerations such as cycle life, temperature sensitivity, and the need for proper battery management, their advantages in performance and design versatility make them a preferred choice for modern, compact, and high-performance devices.

For businesses and engineers seeking custom LiPo battery solutions, we provides expertise in designing tailored batteries that meet specific voltage, capacity, shape, and performance requirements. With experience in curved, flexible, low-temperature, and high-discharge LiPo batteries, LanDazzle helps ensure devices achieve maximum efficiency, safety, and reliability.

Contact LanDazzle today to explore custom solutions and optimize your device’s performance with high-quality, tailored lithium polymer batteries.

Email: info@landazzle.com

Whatsapp: +8618938252128

Related Articles:

Small Lithium Polymer Battery Solutions for Wearable Devices

Li Polymer Battery vs Lithium ion Battery: What’s the Difference