A Brief Introduction to Client Requirements

The client is a global smart-card solutions provider preparing to launch a next-generation payment and access card with advanced security features and integrated sensors. Their design team faced three critical requirements:

Extreme Thinness – The entire power source needed to be no thicker than 1 mm to comply with ISO/IEC smart-card standards while leaving room for antennas, NFC chips, and biometric modules.

Reliable Power & Long Life – The card demanded a stable 3.7 V supply with enough capacity to drive an embedded display and secure authentication electronics for hundreds of charge cycles without degradation.

Flexible & Lightweight Construction – The battery had to withstand daily bending, swiping, and lamination processes without compromising safety or performance, while keeping total weight to just a few grams.

Meeting all three targets simultaneously—especially the sub-1 mm profile paired with high energy density—was the core challenge that brought the client to LanDazzle for a custom solution.

Challenges of Ultra Thin Battery Thickness

Limited Energy Density

The severely constrained thickness limits the amount of active materials (cathode, anode) and the volume of electrolyte inside the battery, resulting in very little space for energy storage. The core challenge is how to maximize energy storage within an extremely thin form factor.

Mechanical Strength and Encapsulation

As the battery becomes thinner, its mechanical strength decreases significantly, making it fragile and susceptible to physical damage (e.g., cracking, delamination) when bent, twisted, or compressed. The encapsulation must be extremely reliable to prevent air/moisture ingress (causing failure) and electrolyte leakage, all while maintaining flexibility.

Thermal Management

The small volume of a thin battery means it has low thermal mass. Heat generated during fast charging or discharging can concentrate more easily, causing rapid localized temperature spikes. This poses significant safety risks (e.g., overheating, fire), making heat dissipation a major challenge.

Manufacturing Process and Yield

Producing ultra-thin batteries requires extremely high precision. Processes like coating, slitting, and stacking/winding of electrode foils and separators are very difficult. They are prone to defects (e.g., pinholes, short circuits), typically resulting in low production yield and high costs.

Cycle Life

The minimal amount of active material means that each charge-discharge cycle causes more significant degradation to the electrodes. This can lead to faster capacity fade and a shorter overall lifespan.

Risk of Internal Short Circuit

The separator itself is extremely thin. Any tiny metallic particles or manufacturing defects can easily pierce the separator, causing the cathode and anode to make direct contact. This leads to an internal short circuit, creating a serious safety hazard.

From Challenge to Reality: Our 1 mm Ultra Thin Smart Card Battery

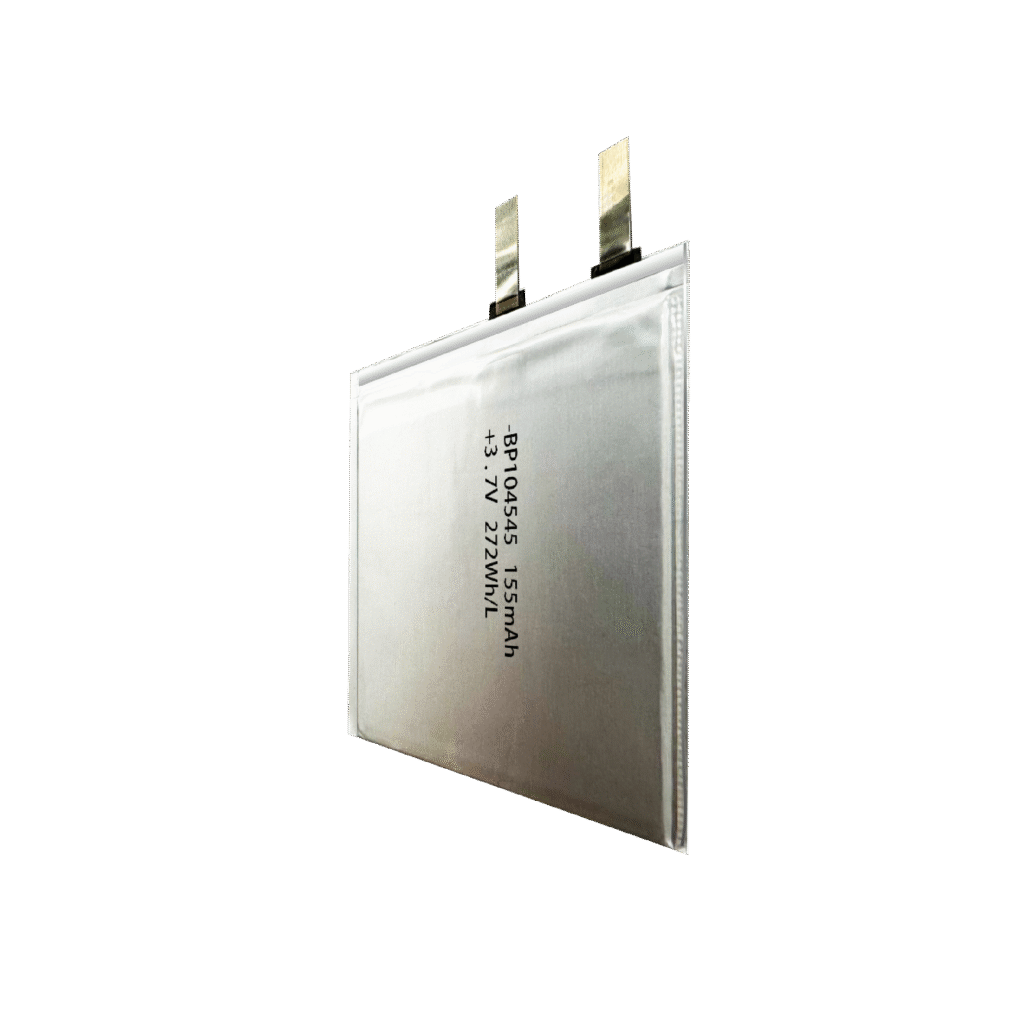

Despite the significant challenges posed by a 1 mm ultra-thin profile, LanDazzle successfully engineered a high-performance ultra thin lipo battery. Our design not only achieves the slim thickness needed for smart cards but also maintains reliable power, long cycle life, and safety.

Capacity: 155 mAh

Provides sufficient energy to power smart card electronics and displays over extended usage.

Voltage: 3.7 V

Delivers a stable 3.7 V output, ensuring reliable operation for embedded devices.

Weight: 3.6 g

Extremely lightweight, contributing to a slim, portable card design without added bulk.

Energy Density: 272 Wh/L

High volumetric energy density maximizes power in minimal space, ideal for ultra-thin applications.

Cycle Life: 500 times

Can sustain up to 500 charge/discharge cycles while maintaining stable performance.

Size: T1.0 × W48 × L44 mm

Ultra-thin 1 mm thickness fits within ISO smart card dimensions while leaving space for antennas and sensors.

How We Solve These Challenges?

Adoption of High-Energy-Density Materials:

High-Voltage Cathodes: LFP, high-nickel NMC (e.g., NMC 811), LCO — store more energy per volume/weight.

Silicon-Carbon Anodes: Higher capacity than graphite; nanostructure and carbon coating reduce expansion.

Solid-State Electrolytes: Partly replace liquid electrolytes, increasing energy density and safety.

Innovative Structural Design & Encapsulation Tech:

- Flexible Stacking Process: Using multi-layer electrode stacking instead of winding.

- Polymer Laminate Encapsulation: Using high-performance pouch film (aluminum composite film) with special lamination processes.

- Integrated Structural Design: Designing the battery to be part of the device’s structure (embedded in a card slot) provides mechanical support.

Material Innovation & Intelligent Design:

- Low Internal Resistance Design: Optimizing tab design and welding processes to reduce internal impedance, minimizing heat generation.

- Thermally Stable Materials: Using high-temperature resistant separators and thermally stable electrolytes to prevent thermal runaway.

- Thermal Interface Management: Using thermal interface materials to efficiently conduct heat from the battery to the device’s metal housing for dissipation.

Precision Manufacturing & Quality Control:

- Ultra-Thin Current Collectors: Using thinner copper and aluminum foils to leave more space for active materials.

- Precision Coating & Slitting: Using high-precision coaters to control coating thickness and uniformity. Laser cutting minimizes burrs and prevents short circuits.

Electrode Interface Stabilization Tech:

- Surface Coating & Modification: Coating cathode/anode materials to reduce side reactions and structural degradation during cycling.

- Functional Electrolyte Additives: Adding film-forming additives to form a stable and robust Solid Electrolyte Interphase (SEI) on the electrode surface, protecting it

Enhanced Separator & Cleanliness Control:

- High-Strength Separators: Using separators based on strong polymers or ceramic-coated separators to improve puncture resistance.

- Cleanroom Manufacturing: Assembling batteries in a high-class cleanroom to strictly control metallic dust and particles

Conclusion

Designing a 1 mm thin lithium polymer battery for smart cards was an ambitious challenge, from extreme space constraints to mechanical flexibility and reliable power requirements. Despite these hurdles, we successfully delivered the BP104545, combining high energy density, long cycle life, and robust mechanical design in an ultra-slim profile.

This battery empowers our client to create sleeker, more versatile products without compromising performance or safety. By leveraging advanced materials, precision stacking, and stringent quality control, LanDazzle demonstrates its ability to turn challenging specifications into real-world, high-performance solutions.

Ready to bring your thin lithium battery project to life?

Contact us today to get a free consultation and explore how our custom battery solutions can bring your devices to life.

Related Articles:

Prismatic vs. Round Batteries: How We Increased Capacity for Smart Watches

Custom Curved Lipo Battery Solves Space Challenge in Smart Rings

Custom High Energy Density Battery: LanDazzle Hits 778 Wh/L for Wireless Power Bank

Zero Wasted Space: LanDazzle Helps Client Overcome Smart Glasses Battery Fit Issues

50% More Battery Space: How LanDazzle Optimized Early Education Robots