Clent Requirements for the Battery

The client specified the following requirements for the battery:

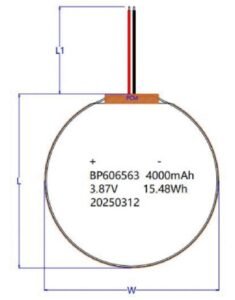

Dimensions: Φ65 × 6.0 mm

Capacity: 4000 mAh

A Φ65 × 6 mm pouch battery is extremely flat, with a thickness of only 6 mm and a diameter of 65 mm.

Analysis of the Battery Requirements

This size corresponds to a battery volume:

V = π r2 h = 3.1416 × (32.5 mm)2 × 6 mm

First, calculate the square of the radius: 32.52 = 1056.25

Multiply by π:

1056.25 × 3.1416 ≈ 3315.9 mm2

Multiply by the thickness 6 mm:

3315.9 × 6 ≈ 19895.4 mm3 ≈ 19.9 cm3

Total effective volume ≈ 20 cm3

The battery is required to have a 4000 mAh capacity. Assuming a nominal voltage of 3.7 V (typical for LiPo), the energy is approximately:

E = 3.7 × 4.0 ≈ 14.8 Wh

Corresponding volumetric energy density:

Volumetric energy density = 14.8 Wh / 19.9 cm3 ≈ 0.744 Wh/cm3 ≈ 744 Wh/L

This means we need to achieve an energy density of 744 Wh/L to meet the customer’s requirements, while standard LiPo batteries only offer 250–600 Wh/L.

How We Make the High Energy Density Battery (778WH/L)?

Using Silicon-Carbon Anodes for High Energy Density

To achieve an exceptional volumetric energy density of 778 Wh/L in our compact battery, we employ silicon-carbon (Si-C) composite anodes. Silicon is known for its extremely high theoretical capacity—about 10 times higher than traditional graphite—which allows more lithium ions to be stored in the same volume, directly boosting the battery’s energy density.

However, incorporating silicon comes with its own challenges:

Volume expansion: Silicon can expand up to 300% during lithiation, which can lead to mechanical stress, cracking, and capacity fading.

Increased weight: Silicon has higher density compared to graphite, which can negatively affect gravimetric energy density.

Electrochemical instability: Silicon can cause excessive formation of the solid electrolyte interphase (SEI), increasing irreversible capacity loss.

We carefully balance these factors through a combination of material design and advanced electrode engineering:

Optimized silicon content: We use a carefully controlled ratio of silicon to carbon in the composite, maximizing energy density without excessive volume expansion or weight gain.

Nano-structured silicon particles: Reducing silicon particle size to the nanoscale mitigates expansion stress and improves cycle stability.

Elastic binders and conductive networks: Special polymeric binders and conductive additives maintain structural integrity and electrical connectivity even as silicon expands during charge/discharge cycles.

Layered electrode architecture: The anode is engineered with graded thickness and porosity to accommodate volume changes, enhancing both safety and longevity.

Precision Electrode Stacking (Layering) Process

We employ a fine-tuned electrode stacking process, carefully controlling the thickness of each electrode layer and separator.

This ensures maximum active material utilization while minimizing wasted space, which is crucial for achieving volumetric energy densities close to 778 Wh/L.

Tight tolerances in electrode alignment reduce internal resistance and improve power delivery.

Optimized Cathode Formulation

High-capacity cathode materials are blended to balance energy density, cycle life, and thermal stability.

Cathode coating thickness is precisely controlled to match the anode’s characteristics, ensuring uniform lithiation and minimal stress during charge/discharge.

Advanced Electrolyte System

We use high-conductivity, low-viscosity electrolytes that enhance ion transport even in densely packed electrodes.

Additives are selected to form a stable SEI layer, mitigating degradation of the silicon anode and improving cycle life.

Thermal and Mechanical Management

Advanced cell design accounts for heat dissipation and mechanical expansion, especially important with silicon anodes.

Flexible packaging and controlled pressure distribution prevent deformation and maintain long-term stability.

Finished Product: High Energy Density Battery (778 Wh/L)

Custom Round Battery Design

High Energy Density: 778Wh/L

Lightweight Construction: 47g

Low Internal Resistance

Silicon-Carbon Anode Technology

Higher Nominal Voltage: 3.87V

Conclusion

Our achievement of 778 Wh/L energy density demonstrates our ability to push the limits of compact battery design. By combining silicon-carbon anodes, precision electrode stacking, and robust thermal management, we have created a battery that is not only ultra-compact but also highly reliable, safe, and long-lasting.

This high energy density battery is ideal for compact applications such as wireless power banks, portable electronics, and other space-constrained devices. Our innovative approach ensures that clients can enjoy maximum performance without compromising safety or longevity.

With LanDazzle, achieving cutting-edge battery solutions for even the most challenging compact applications is not just a goal—it’s our standard.

Ready to take your product to the next level? Contact us today for a free consultation and discover how our custom LiPo battery solutions can elevate your wearable device.

Related Articles:

Custom 1mm Ultra Thin Battery Enables High-Performance Smart Cards

Custom Curved Lipo Battery Solves Space Challenge in Smart Rings

Prismatic vs. Round Batteries: How We Increased Capacity for Smart Watches

Zero Wasted Space: LanDazzle Helps Client Overcome Smart Glasses Battery Fit Issues

50% More Battery Space: How LanDazzle Optimized Early Education Robots